- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen – Durable, High-Flow, OEM Factory

Shale Shaker Screen is a key solution in the energy industry, specifically within Oil and Gas and Oil and gas drilling and production equipment and services. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Shale Shaker Screen Overview

- Benefits & Use Cases of Shale Shaker Screen in Oil and gas drilling and production equipment and services

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in energy

- Conclusion on Shale Shaker Screen from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Shale Shaker Screen Overview

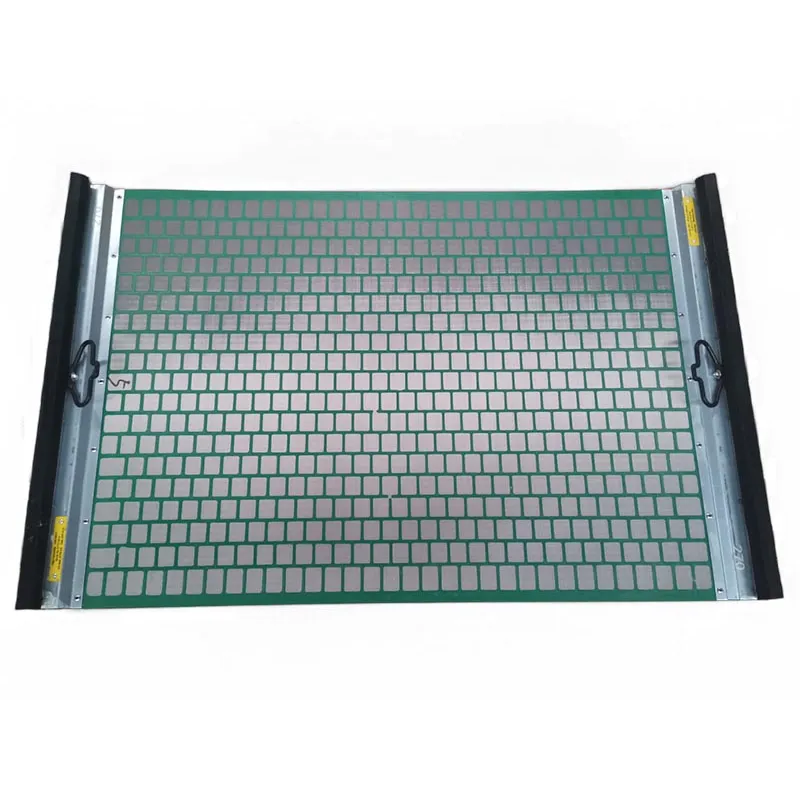

In drilling fluids processing, the shale shaker is the primary solids control stage—and the screen is its heart. A Shale Shaker Screen is a layered wire mesh panel that separates drilled solids from mud, protecting downstream equipment and preserving mud properties. Built on composite or steel frames with precisely selected shale shaker screen mesh counts, it delivers the cut point and conductance your program demands. Anping County Hangshun Wire Mesh Manufacture Co., Ltd designs and manufactures screens that align with API RP 13C for consistent D100 results, available in multiple mesh ranges (from coarse to fine) and configurations (2–4 layers) for water-, oil-, and synthetic-based muds.

Typical specifications include corrosion-resistant stainless steel mesh, bonded or welded to high-strength frames, with robust perimeter seals to minimize by-pass. Options include pyramid/flat profiles, reinforced repairable panels, and anti-blinding systems for sticky formations. Our manufacturing in Anping—China’s wire-mesh capital—equips us as a dependable shale shaker screen factory with tight QC and rapid delivery. If you’re benchmarking a shale shaker screen China supplier, Hangshun combines technical support with flexible OEM/ODM solutions to match rig-specific deck dimensions and quick-lock systems.

Benefits & Use Cases of Shale Shaker Screen in Oil and gas drilling and production equipment and services

Across land rigs, offshore platforms, and HDD rigs, operators rely on the shaker to control drilled solids, reduce dilution, and extend mud life. High-performance Shale Shaker Screens maximize non-blanked area and conductance to move large volumes while holding the target cut point. This improves centrifuge efficiency, reduces desander/desilter load, and protects pumps and MWD/LWD tools from abrasive particles. Hangshun screens are engineered for stable tension, edge sealing, and fast installation—so crews maintain flow and cut NPT associated with screen changeouts and overflow events.

- Applications: surface hole with gumbo, intermediate hole with high-solids rates, and production zones requiring precise fine solids removal; compatible with leading shaker models and deck geometries.

- Competitive advantages: API RP 13C compliance, durable composite frames, optimized wire grades, anti-corrosion coatings, and mesh selections tailored to ROP, mud weight, and rheology.

- Expertise: As a focused shale shaker screen factory, Anping County Hangshun Wire Mesh Manufacture Co., Ltd provides engineering recommendations on mesh layering, screen panel count per deck, and changeout strategy to balance rate and recovery.

Cost, Maintenance & User Experience

For B2B decision makers, total cost of ownership extends beyond the headline shale shaker screen price. The real ROI comes from screen life, stable cut point, reduced dilution, and minimized downtime. Hangshun’s composite frames resist warping and corrosion, helping extend service life and maintain deck sealing integrity. Consistent shale shaker screen mesh specification lowers the risk of mud property swings, improving solids control efficiency and reducing centrifuge and pump wear. Bulk packaging and optimized logistics from our shale shaker screen China facility further control landed cost.

- Maintenance guidance: select API-designated mesh for formation changes; check deck tensioning and gaskets; adjust deck angle for flow; wash with appropriate pressure to avoid delamination; store screens flat and dry.

- User feedback: drilling teams value fast fit-up, predictable performance across long runs, and local stocking options. Procurement teams appreciate transparent pricing tiers, technical documentation, and QA traceability per batch.

Sustainability & Market Trends in energy

Stricter waste regulations and ESG mandates are reshaping solids control. High-efficiency Shale Shaker Screens cut drilled solids at the first stage, improving fluid recovery and reducing waste volumes and hauling. This supports operator targets for lower emissions and responsible resource use while maintaining rate of penetration. As the market standardizes around API RP 13C and higher performance composites, procurement increasingly favors suppliers that combine process know-how with verifiable QA and responsible sourcing.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd invests in material selection, repeatable mesh weaving, and recyclable packaging—positioning the company as a forward-thinking partner. Our shale shaker screen factory emphasizes quality control and continuous improvement to deliver screens that last longer and reduce waste handling. For operators balancing cost, compliance, and performance, partnering with a dependable shale shaker screen China manufacturer ensures supply chain resilience and consistent field results across global rig fleets.

Conclusion on Shale Shaker Screen from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

From surface hole to production intervals, a well-chosen Shale Shaker Screen safeguards mud systems, cuts waste, and protects downstream equipment. Anping County Hangshun Wire Mesh Manufacture Co., Ltd delivers API-aligned mesh options, robust frames, and responsive service—helping drilling teams reduce NPT and optimize total cost of ownership. For reliable supply from a proven shale shaker screen factory, we’re ready to support your next well.

- Contact us: email: sales@hfpetromesh.com

- Visit our website: https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025