- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

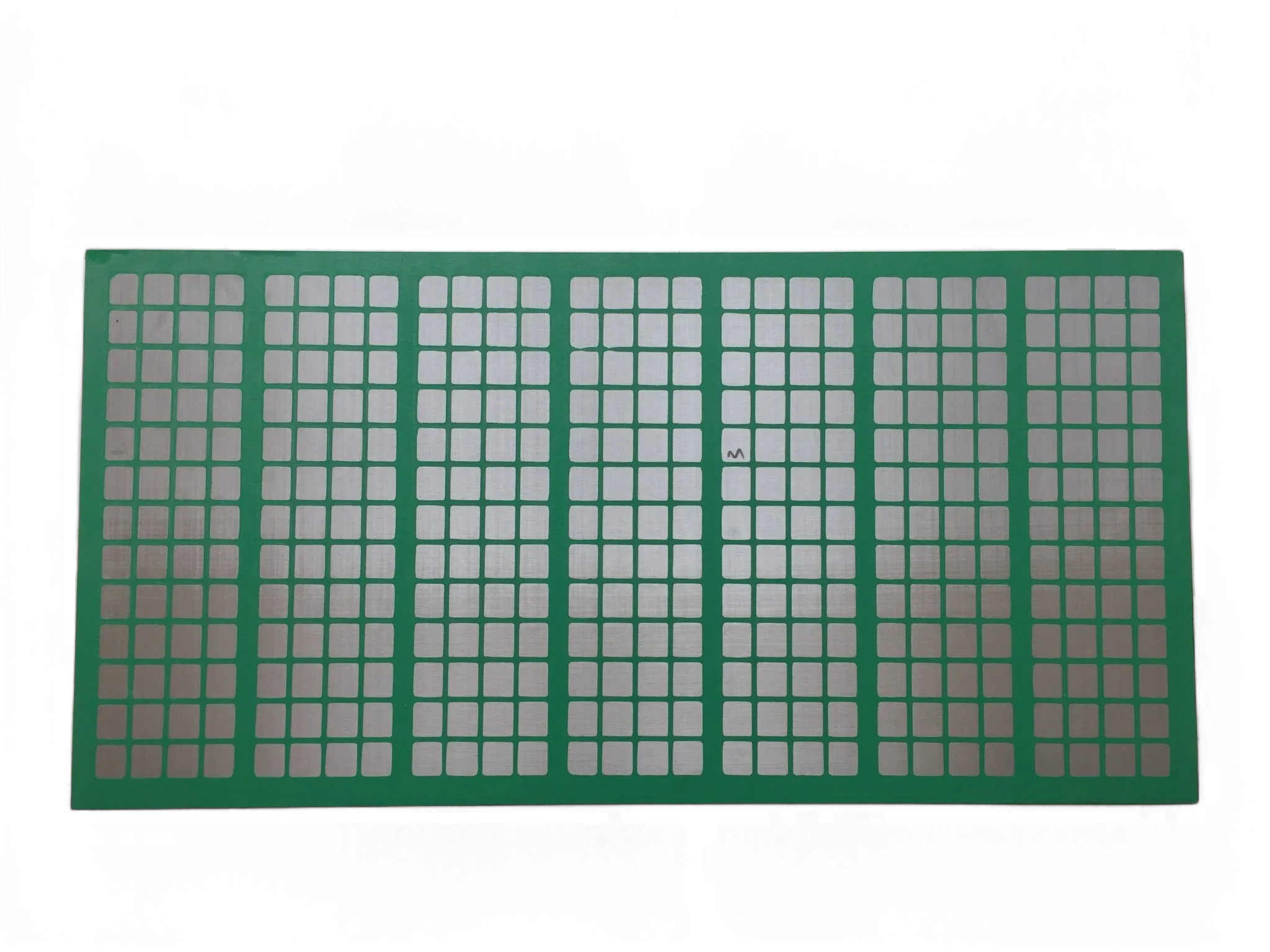

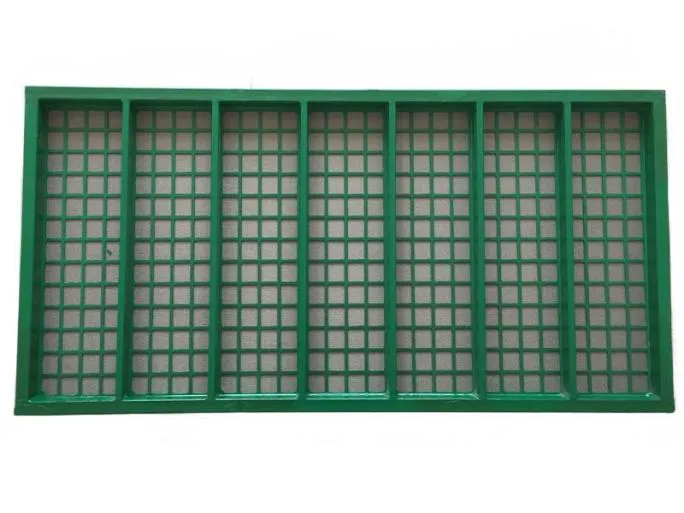

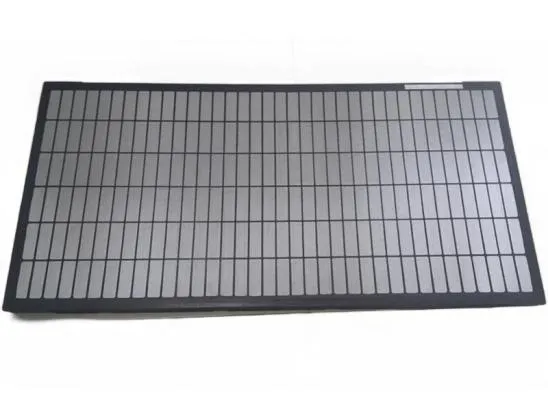

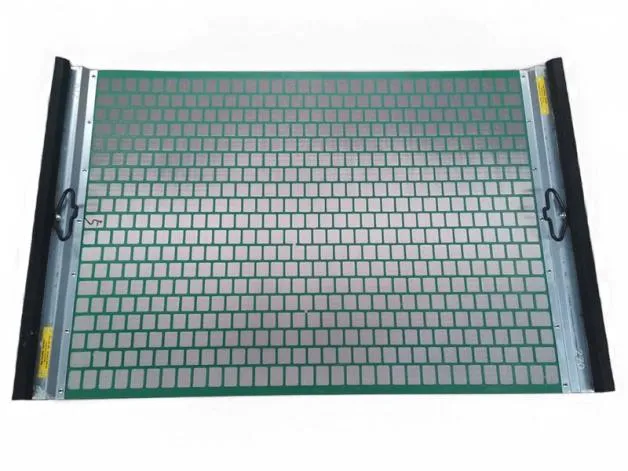

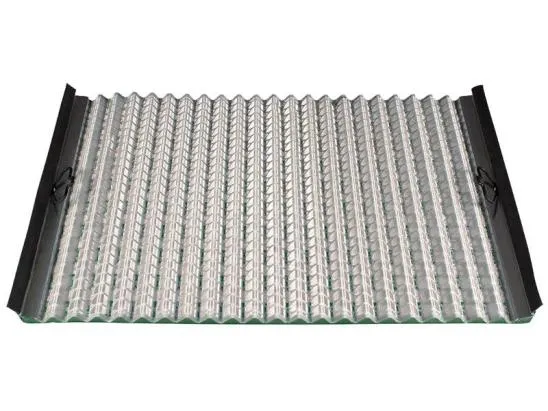

Shale Shaker Screen - Anping | High Strength, Filtration

The Shale shaker screen is a critical component in modern drilling operations, designed to efficiently separate solid cuttings from drilling fluids. This advanced mesh technology plays a pivotal role in maintaining the integrity of drilling processes across various industries, including oil and gas exploration, coal bed methane extraction, and environmental remediation projects.

Key Features and Advantages

- High Strength and Load Capacity: Engineered with stainless steel or carbon steel wire cloths, these screens withstand heavy drilling fluid weights while maintaining structural integrity.

- Exceptional Filtration Accuracy: Multi-layered (dual or triple) mesh configurations ensure precise separation of solid particles, with options like wave screens offering optimal processing efficiency.

- Corrosion and Wear Resistance: Advanced surface treatments enhance durability in harsh drilling environments, reducing maintenance frequency.

- Adaptability: Available in steel frame, composite frame, and hook strip designs, these screens accommodate various shale shaker models and operational conditions.

- Superior Flexibility: The design prevents common defects like deformation or metal spatter, ensuring smooth installation and long-term performance.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Stainless steel, carbon steel |

| Surface Treatment | Coating (black, green, blue, or custom colors) |

| Production Process | Weaving and perforating |

| Standards Compliance | ISO 13501, API RP 13C, GBT 11648, GBT 11650 |

| Types | Steel frame, composite frame, hook strip, wave screens |

Applications in Modern Drilling Operations

The shale shaker screen is indispensable in several critical applications:

- Oil and Gas Drilling: Removes cuttings from drilling mud, ensuring fluid efficiency and equipment longevity.

- Horizontal Directional Drilling: Enhances precision in non-excavation projects by maintaining fluid cleanliness.

- Coal Bed Methane and Shale Gas Extraction: Critical for managing drilling fluids in unconventional reservoirs.

- Environmental Remediation: Purifies sludge and contaminated fluids in river and soil cleanup projects.

Company Background: Anping County Hangshun Wire Mesh Manufacture Co., Ltd

As a leading manufacturer in the wire mesh industry, Anping County Hangshun Wire Mesh Manufacture Co., Ltd specializes in producing high-performance shale shaker screens tailored to global drilling requirements. With a commitment to innovation and quality, the company adheres to international standards, ensuring products meet the rigorous demands of modern drilling operations.

Industry Standards and Certification

The shale shaker screen complies with critical industry standards such as ISO 13501 and API RP 13C, which are referenced in NIST (National Institute of Standards and Technology) guidelines for manufacturing precision equipment. According to NIST, adherence to such standards ensures "consistent quality and performance in industrial applications" (NIST, 2023). This alignment with recognized benchmarks underscores the product's reliability and technical excellence.

Choosing the Right Screen for Your Needs

With options like steel frame screens for heavy-duty use or wave screens for maximum efficiency, the company offers customizable solutions. Factors such as drilling fluid weight, cuttings size, and operational environment determine the optimal choice.

Conclusion

The shale shaker screen represents a convergence of advanced materials, precise engineering, and industry expertise. By integrating cutting-edge technology with rigorous quality controls, Anping County Hangshun Wire Mesh Manufacture Co., Ltd continues to set benchmarks in drilling fluid management. For further details, visit the product page or explore the company website.

References

NIST (National Institute of Standards and Technology). (2023). "Standards for Industrial Equipment." Retrieved from https://www.nist.gov/

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025