- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen - Anping County Hangshun Wire Mesh Manufacture Co., Ltd | High-Efficiency Separation, Durable Filtration

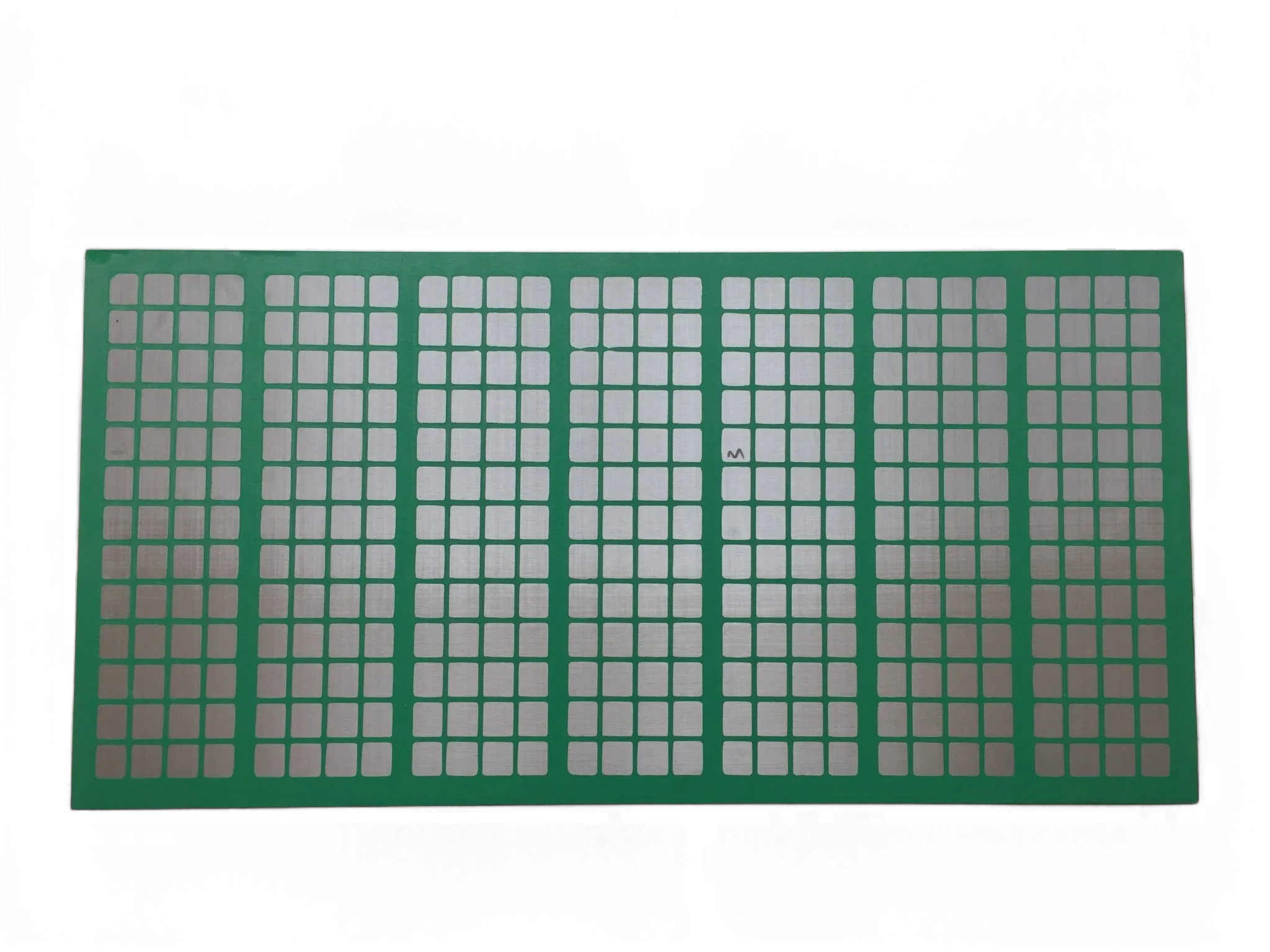

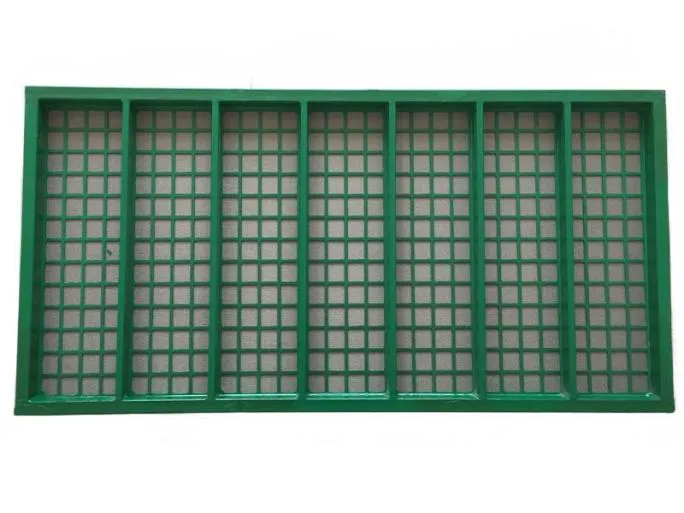

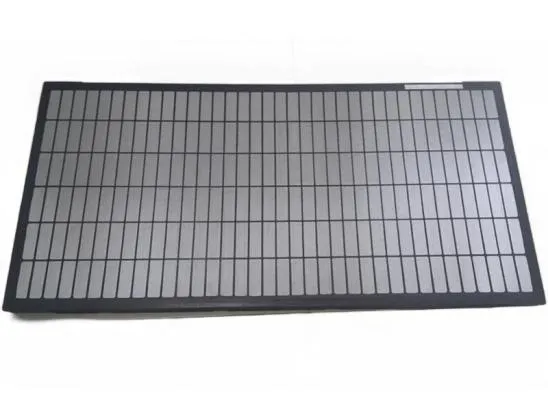

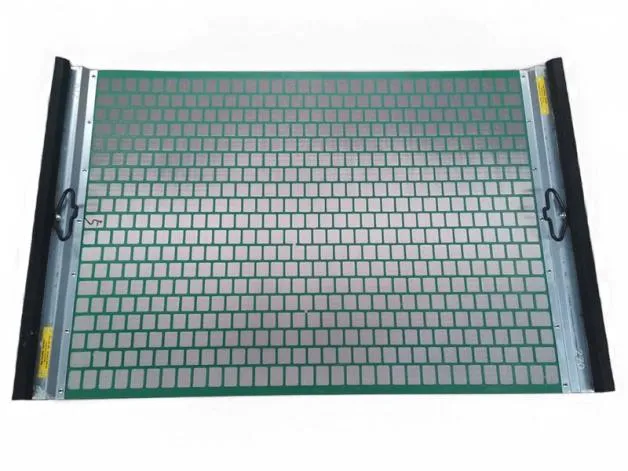

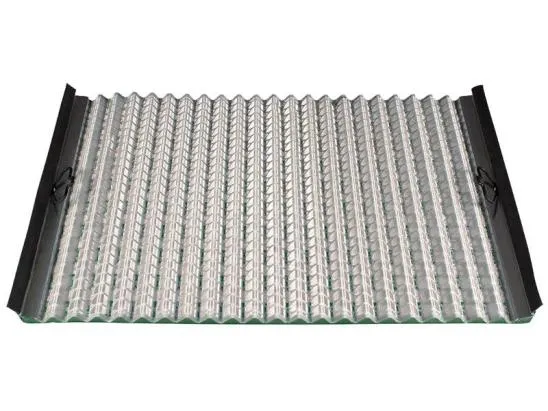

Shale shaker screen is a critical component in the drilling industry, designed to filter and separate solid cuttings from drilling mud. This fine mesh screen, often composed of multiple layers of stainless steel wire cloth, plays a pivotal role in maintaining the efficiency and sustainability of drilling operations. By capturing solid particles and allowing excess mud to drain back into the tank, shale shaker screens ensure optimal performance in various drilling environments.

Manufactured by Anping County Hangshun Wire Mesh Manufacture Co., Ltd, these screens are engineered to meet the rigorous demands of modern drilling systems. The company's commitment to quality and innovation is evident in the advanced materials and precise manufacturing processes used in their products.

Product Images

Key Features of Shale Shaker Screens

- High Strength and Bearing Capacity: Engineered to withstand the heavy loads of drilling fluids, ensuring durability under demanding conditions.

- Excellent Filtering Accuracy: Multi-layered stainless steel wire cloth provides precise separation of solids from drilling mud.

- Superior Processing Efficiency: Designs like wave screens maximize throughput while maintaining high filtration efficiency.

- Wear and Corrosion Resistance: Advanced surface treatments enhance longevity, even in harsh environments.

- Flexibility and Adaptability: Available in various types (steel frame, composite frame, wave, etc.) to suit different drilling equipment and conditions.

- Easy Installation and Maintenance: User-friendly design reduces downtime and simplifies routine maintenance tasks.

Product Specifications

| Specification | Details |

|---|---|

| Material | Stainless steel, carbon steel |

| Surface Treatment | Coating (black, green, blue, or custom colors) |

| Production Process | Weaving and perforating |

| Type | Steel or composite frame screen, hook strip screen, wave screen |

| Standards | ISO 13501, API RP 13C, GBT 11648, GBT 11650 |

Applications in the Drilling Industry

Shale shaker screens are indispensable in a wide range of drilling operations, including:

- Oil Drilling: Efficient separation of cuttings from drilling mud to maintain fluid integrity.

- Non-Excavation Horizontal Directional Crossing: Ensures minimal environmental impact by purifying drilling fluids.

- Coal Bed Methane Drilling: Enhances efficiency in extracting methane from coal seams.

- Shale Gas Drilling: Critical for processing large volumes of drilling fluid in unconventional gas operations.

- Environmental Protection: Used in river sludge treatment to purify water and reduce contamination.

These screens are also vital in solid control systems, where they contribute to the sustainability and cost-effectiveness of drilling projects.

About Anping County Hangshun Wire Mesh Manufacture Co., Ltd

As a leading manufacturer in the wire mesh industry, Anping County Hangshun Wire Mesh Manufacture Co., Ltd specializes in producing high-quality shale shaker screens tailored to the needs of the drilling sector. With a focus on innovation and precision, the company adheres to international standards such as ISO 13501 and API RP 13C, ensuring that their products meet the highest quality benchmarks.

The company's commitment to excellence is reflected in its advanced production processes and rigorous quality control measures. By leveraging cutting-edge technology and skilled craftsmanship, Hangshun Wire Mesh delivers solutions that enhance the efficiency and reliability of drilling operations worldwide.

Industry Standards and Certifications

The shale shaker screens produced by Anping County Hangshun Wire Mesh Manufacture Co., Ltd are designed to comply with stringent industry standards. These include:

- ISO 13501: Specifies requirements for the design and testing of shaker screens.

- API RP 13C: A recommended practice for the operation and maintenance of shale shakers.

- GBT 11648 and GBT 11650: Chinese national standards for wire mesh and screening equipment.

These certifications underscore the company's dedication to quality and safety, ensuring that their products meet the expectations of global customers.

Relevance to NIST Standards

The National Institute of Standards and Technology (NIST) plays a crucial role in establishing standards that ensure the accuracy and reliability of industrial equipment. While NIST does not directly regulate shale shaker screens, its work in material science and measurement standards underpins the development of high-performance drilling components.

For instance, NIST's research on materials science contributes to the creation of durable and corrosion-resistant materials used in drilling equipment. Additionally, NIST's standards for scientific uncertainty ensure that measurements in drilling operations are precise and consistent.

By aligning with NIST's principles of precision and reliability, Anping County Hangshun Wire Mesh Manufacture Co., Ltd ensures that its shale shaker screens meet the highest standards of performance and safety.

Conclusion

Shale shaker screens are essential tools in the drilling industry, offering efficient separation of solids from drilling fluids while maintaining operational efficiency. The products from Anping County Hangshun Wire Mesh Manufacture Co., Ltd exemplify the perfect blend of innovation, durability, and precision, making them a trusted choice for drilling professionals worldwide.

With a wide range of applications and adherence to international standards, these screens not only enhance the performance of drilling systems but also contribute to environmental sustainability. As the demand for efficient and reliable drilling solutions continues to grow, the role of high-quality shale shaker screens becomes increasingly vital.

References

1. National Institute of Standards and Technology (NIST). Retrieved from https://www.nist.gov

2. Anping County Hangshun Wire Mesh Manufacture Co., Ltd. Retrieved from https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025