- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

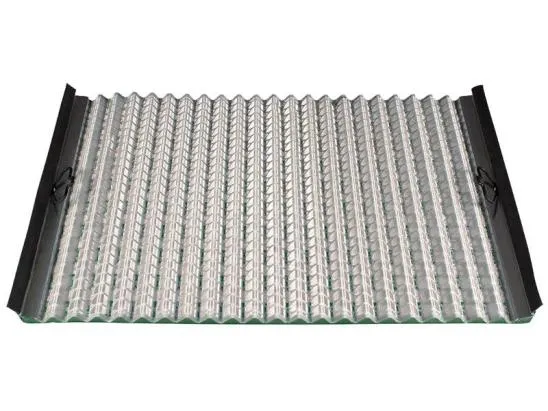

Shale Shaker Screen - Anping County Hangshun Wire Mesh Manufacture Co., Ltd | Drilling Fluid Separation, High Strength Filtering

Shale shaker screen is a critical component in drilling operations, designed to separate drilling cuttings from mud. This fine mesh, often composed of stainless steel wire cloths, ensures efficient filtration and solid control, making it indispensable in the oil and gas industry.

Introduction to Shale Shaker Screens

Shale shaker screens are specialized mesh screens installed in shale shakers to filter and separate solid particles from drilling fluids. These screens are essential for maintaining the quality of drilling mud, which is crucial for efficient drilling operations. The screens are typically made of multiple layers of stainless steel wire cloths, offering high filtering accuracy and durability.

Key Features of Shale Shaker Screens

- High Strength and Bearing Capacity: Engineered to withstand heavy drilling fluids and abrasive cuttings.

- Excellent Processing Efficiency: Optimized for high throughput and minimal downtime.

- Wear and Corrosion Resistance: Long-lasting performance in harsh drilling environments.

- Flexibility: Compatible with various shale shaker models and drilling conditions.

- Superior Appearance: Free from defects like bumps, deformation, or solder spatter.

- Easy Installation and Maintenance: Designed for quick replacement and minimal upkeep.

Product Specifications

| Parameter | Details |

|---|---|

| Material | Stainless steel, carbon steel |

| Surface Treatment | Coating (black, green, blue; customizable) |

| Production Process | Weaving and perforating |

| Type | Steel or composite frame screen, hook strip screen, wave screen |

| Standards | ISO 13501, API RP 13C, GBT 11648, GBT 11650 |

Applications in Drilling Operations

Shale shaker screens are widely used in various drilling scenarios, including:

- Oil Drilling: Ensuring efficient separation of cuttings from drilling mud.

- Non-Excavation Horizontal Directional Crossing: Maintaining fluid purity in trenchless drilling.

- Coal Bed Methane and Shale Gas Drilling: Enhancing the efficiency of mud recycling systems.

- Environmental Protection: Purifying sludge and reducing waste in river and soil remediation projects.

Types of Shale Shaker Screens

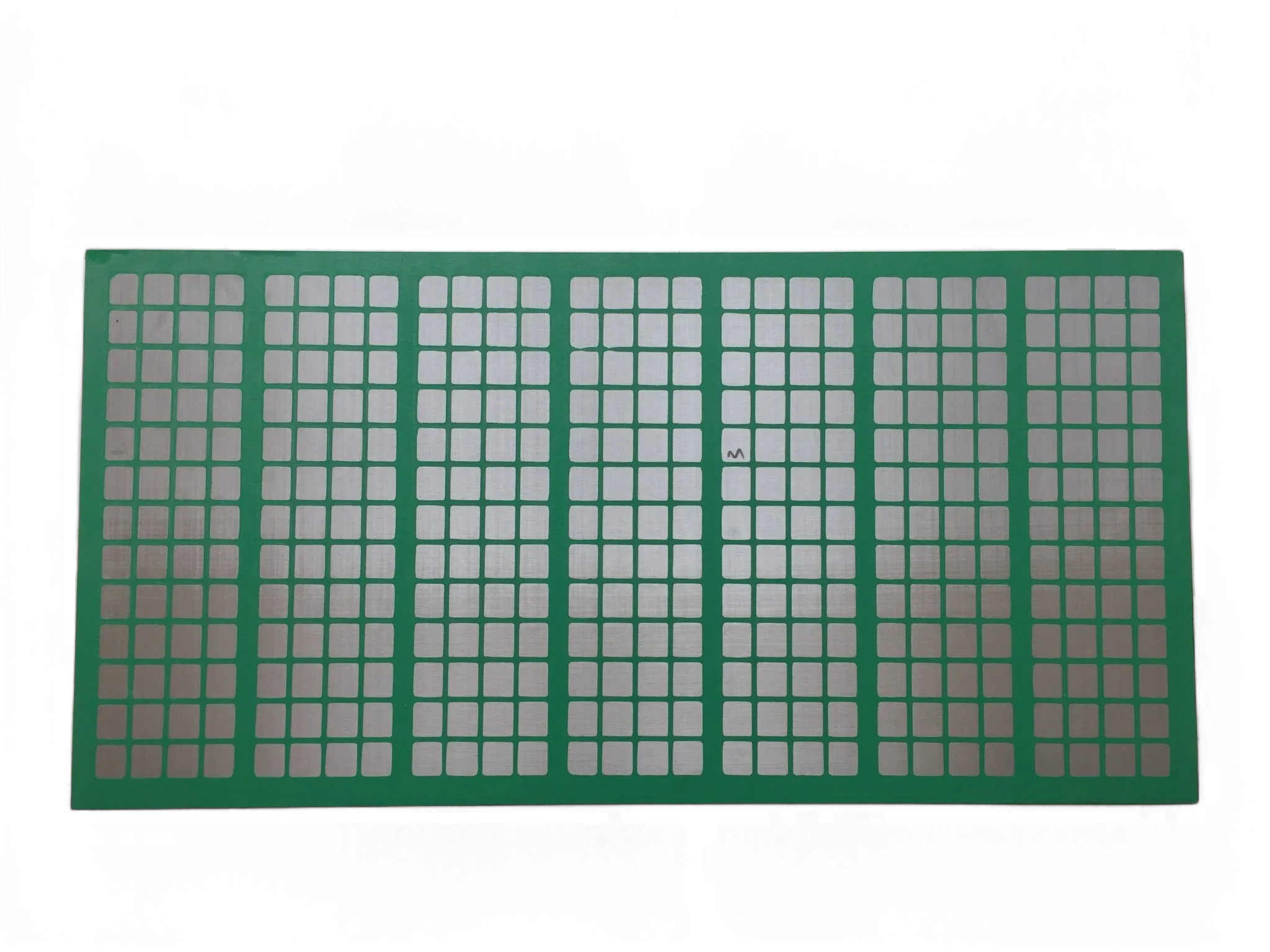

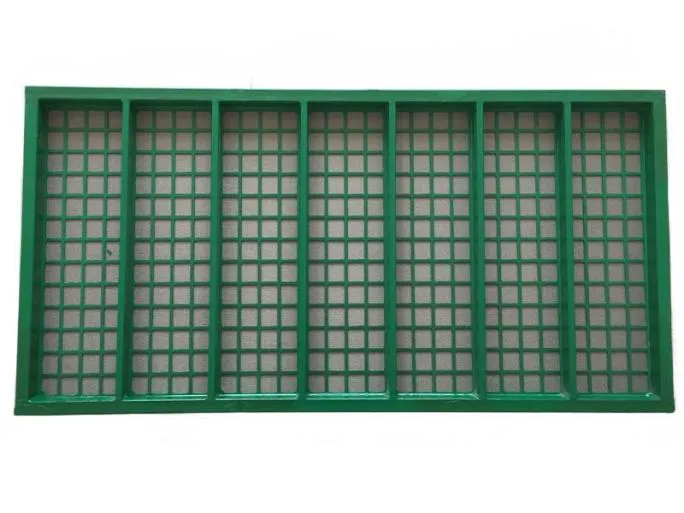

Steel Frame Screen: Offers high load-bearing capacity, ideal for heavy-duty drilling. Shale Shaker Screen for detailed specifications.

Composite Frame Screen: Combines durability with flexibility, suitable for diverse drilling conditions.

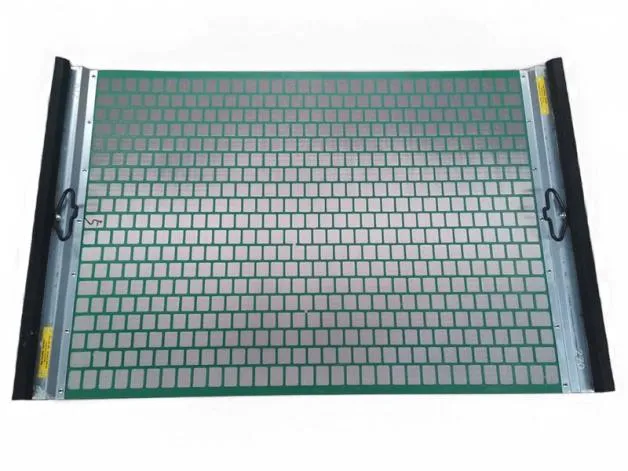

Wave Screen: Provides the best processing efficiency, ideal for high-volume operations. Shale Shaker Screen Mesh for advanced filtration solutions.

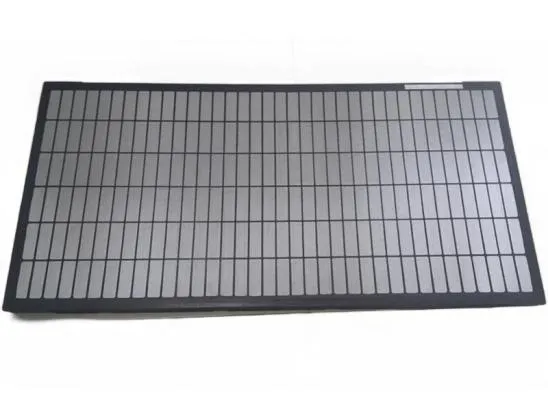

Hook Strip Screen: Designed for easy installation and maintenance, ensuring minimal downtime.

Company Background: Anping County Hangshun Wire Mesh Manufacture Co., Ltd.

As a leading manufacturer in the wire mesh industry, Anping County Hangshun Wire Mesh Manufacture Co., Ltd. specializes in producing high-quality shale shaker screens tailored to meet global drilling demands. With a commitment to innovation and precision, the company adheres to international standards such as ISO 13501 and API RP 13C, ensuring reliability and performance in every product. Shale Shaker Screen Factory offers a wide range of solutions for oil and gas, environmental, and industrial applications.

Why Choose Our Shale Shaker Screens?

Our shale shaker screens are engineered to deliver unmatched efficiency and durability. Whether you're drilling for oil, gas, or in environmental projects, our products are designed to handle the harshest conditions while maintaining optimal performance. Shale Shaker Screen Price offers cost-effective solutions without compromising on quality.

Industry Standards and Certifications

Compliance with industry standards is a cornerstone of our manufacturing process. Our products meet the following certifications:

- ISO 13501: Ensures quality management systems for consistent product performance.

- API RP 13C: Standards for drilling and production equipment, ensuring safety and reliability.

- GBT 11648 and GBT 11650: Chinese national standards for wire mesh and screening equipment.

Enhancing Drilling Efficiency with Advanced Technology

According to the National Institute of Standards and Technology (NIST), precision in material specifications is critical for industrial applications. NIST emphasizes the importance of accurate measurements in ensuring the longevity and performance of drilling equipment. Our shale shaker screens are designed with these principles in mind, offering precise filtration and robust construction.

Conclusion

In summary, shale shaker screens are vital for maintaining the efficiency and sustainability of drilling operations. With their advanced features, compliance with international standards, and tailored solutions for diverse applications, Anping County Hangshun Wire Mesh Manufacture Co., Ltd. stands as a trusted partner in the oil and gas industry. For more information, visit our Shale Shaker Screen page.

References

NIST (National Institute of Standards and Technology). "Standards and Measurements." https://www.nist.gov/

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025