- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen-Anping County Hangshun Wire Mesh Manufacture Co., Ltd.|Precision Drilling Fluid Separation&Durability

Shale shaker screen is a critical component in modern drilling operations, designed to efficiently separate drilling cuttings from mud. This advanced mesh technology ensures optimal performance in various industrial applications, from oil and gas extraction to environmental protection projects.

Introduction to Shale Shaker Screen

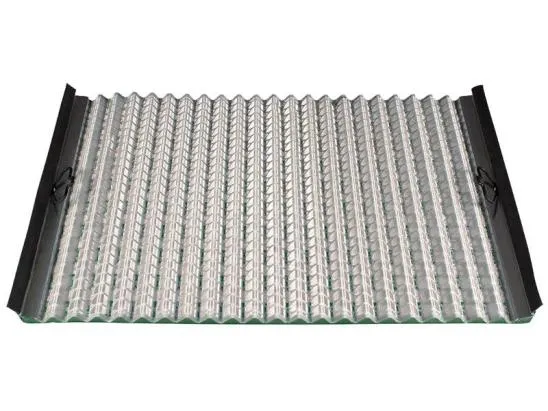

The Shale Shaker Screen is a specialized mesh screen installed in shale shakers, which are essential in drilling fluid management systems. These screens are typically constructed from stainless steel or carbon steel wire cloths, arranged in dual or triple layers to achieve precise filtration. The primary function of the screen is to capture solid particles while allowing excess drilling fluid to drain back into the system, ensuring efficient solids control.

Manufactured using weaving and perforating processes, the shale shaker screen is engineered to withstand the demanding conditions of drilling environments. Its design allows for high strength, high bearing capacity, and excellent filtering accuracy. The screen's versatility is evident in its ability to adapt to different drilling scenarios, making it a preferred choice for operators seeking reliable and durable solutions.

Key Features of Shale Shaker Screen

- High Strength and Bearing Capacity: The screen's robust construction ensures it can handle heavy loads of drilling fluid without deformation.

- Excellent Filtering Accuracy: The multi-layered design allows for precise separation of fine particles, enhancing the efficiency of the drilling fluid recycling process.

- Wear and Corrosion Resistance: The use of high-quality materials ensures longevity even in harsh environments.

- Good Flexibility: The screen is compatible with various types of shale shakers, offering adaptability to different operational needs.

- Easy Installation and Maintenance: The design simplifies the process of replacing or repairing the screen, reducing downtime.

Product Specifications

| Specification | Details |

|---|---|

| Material | Stainless steel, carbon steel |

| Surface Treatment | Coating (black, green, blue, or custom colors) |

| Production Process | Weaving and perforating |

| Type | Steel frame, composite frame, hook strip, wave screen |

| Standards | ISO 13501, API RP 13C, GBT 11648, GBT 11650 |

Types of Shale Shaker Screen

There are several types of shale shaker screens, each tailored to specific drilling conditions:

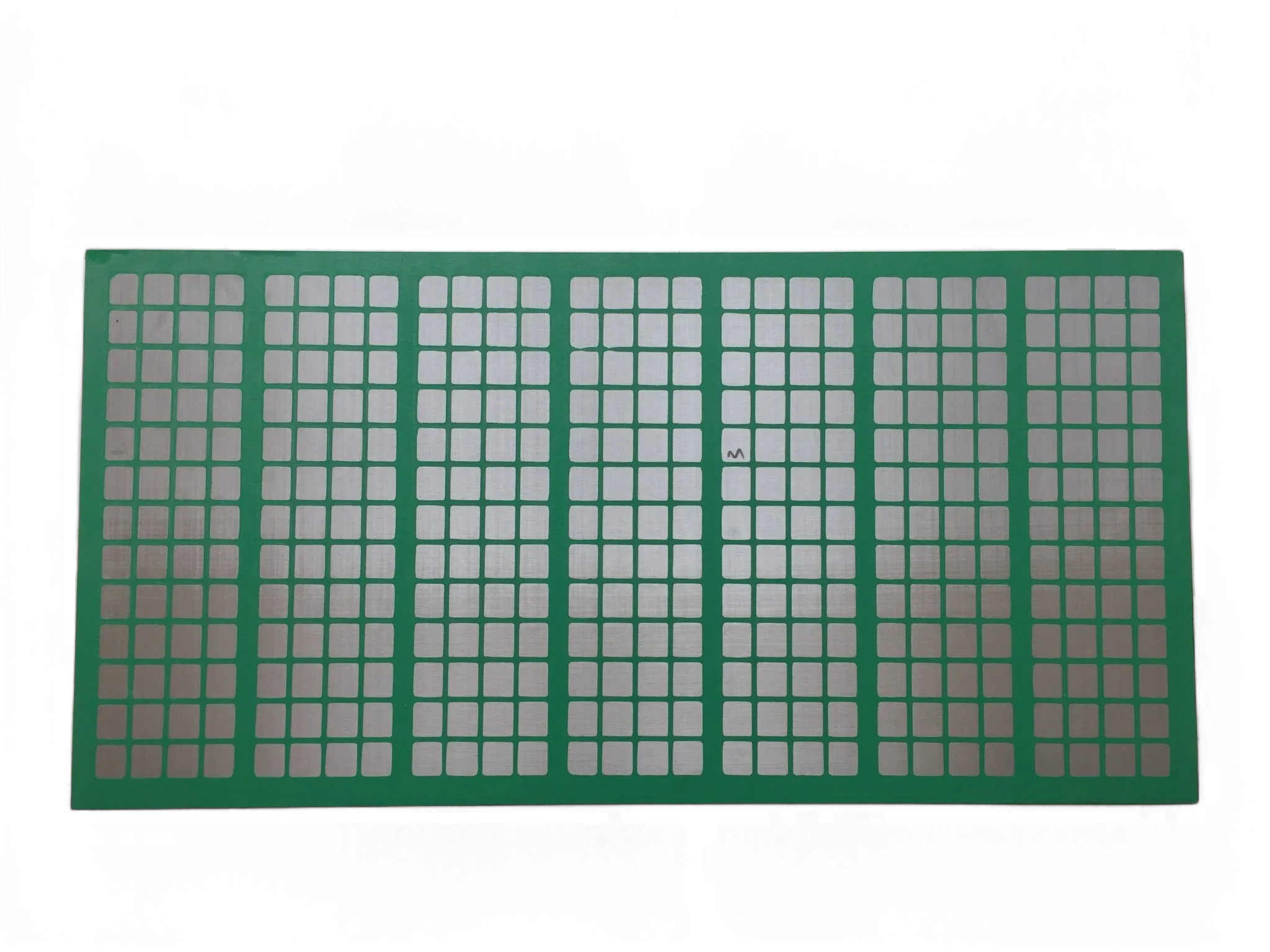

- Steel Frame Screen: Known for its high weight-bearing capacity, this type is ideal for heavy-duty applications.

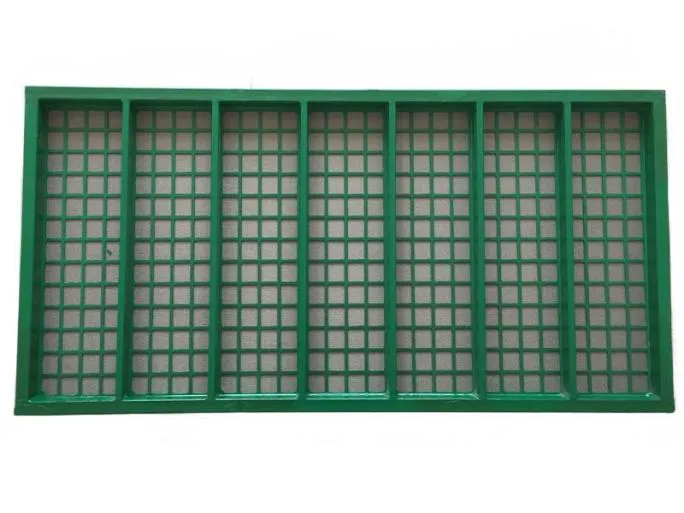

- Composite Frame Screen: Combines the benefits of multiple materials for enhanced durability and flexibility.

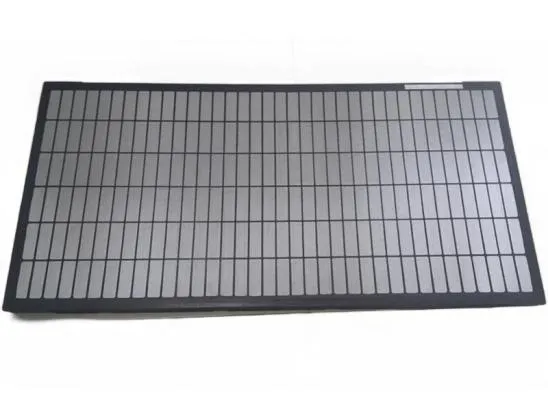

- Hook Strip Screen: Designed for easy installation and maintenance, this type is popular in environments requiring frequent screen changes.

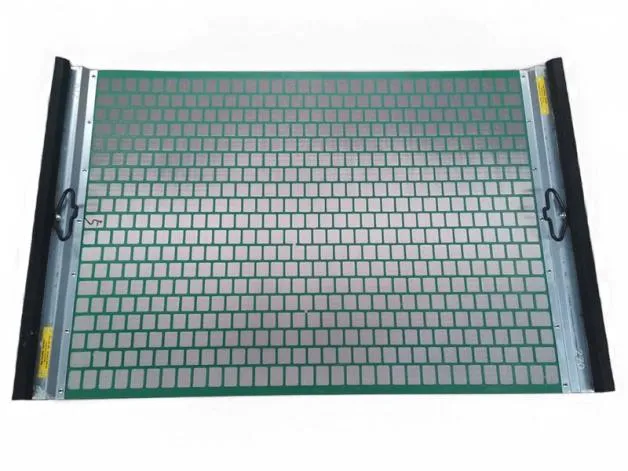

- Wave Screen: Offers the best processing efficiency, making it suitable for high-volume drilling operations.

Steel Frame Shale Shaker Screen is engineered to withstand the heaviest loads, ensuring reliable performance in demanding drilling environments.

Composite Frame Shale Shaker Screen combines the strengths of different materials, offering a balance of durability and flexibility.

Hook Strip Flat Shale Shaker Screen is designed for quick installation and maintenance, minimizing operational downtime.

Wave Shale Shaker Screen provides superior processing efficiency, making it ideal for high-volume drilling operations.

Applications of Shale Shaker Screen

The Shale Shaker Screen is widely used in the following industries:

- Oil and Gas Drilling: Essential for separating cuttings from drilling mud, ensuring efficient fluid recycling.

- Non-Excavation Horizontal Directional Crossing: Used to manage drilling fluids in trenchless construction projects.

- Coal Bed Methane Drilling: Helps in the efficient extraction of methane by maintaining clean drilling fluids.

- Shale Gas Drilling: Critical for separating solids from the drilling fluid in unconventional gas extraction.

- Environmental Protection: Applied in sludge treatment and mud purification systems to reduce environmental impact.

Wave Shale Shaker Screen is specifically designed for shale shaker machines, ensuring optimal performance in gas and oil drilling operations.

Composite Frame Shaker Screen Machine combines durability and flexibility, making it suitable for a wide range of drilling applications.

Steel Frame Shaker Screen Machine is built to handle the heaviest drilling loads, ensuring reliable performance in demanding environments.

Hook Strip Shaker Screen Machine offers quick installation and maintenance, reducing downtime and improving operational efficiency.

Company Background: Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Founded in [year], Anping County Hangshun Wire Mesh Manufacture Co., Ltd is a leading manufacturer of high-quality wire mesh products, including shale shaker screens. The company specializes in producing shale shaker screen mesh, shale shaker screen price, and shale shaker screen factory solutions tailored to meet the needs of the oil and gas industry.

With a commitment to quality, innovation, and customer satisfaction, Anping County Hangshun Wire Mesh Manufacture Co., Ltd. has established itself as a trusted supplier of drilling fluid management systems. The company's products are widely used in various industrial applications, including shale shaker screen china and shale shaker screen factory operations.

For more information about the company and its products, visit the Shale Shaker Screen page on their official website.

Conclusion

The Shale Shaker Screen is an essential component in modern drilling operations, offering superior performance in solids control and fluid management. With its advanced design, durable construction, and adaptability to various drilling conditions, the screen ensures efficient and reliable operation in the oil and gas industry.

For shale shaker screen mesh, shale shaker screen price, and shale shaker screen china solutions, Anping County Hangshun Wire Mesh Manufacture Co., Ltd. provides high-quality products that meet international standards. Their commitment to innovation and customer satisfaction makes them a trusted partner in the drilling industry.

References

Authoritative Sources:

- National Institute of Standards and Technology (NIST) – Standards and measurement guidelines for industrial equipment.

Standards Compliance:

- ISO 13501:2012 – Safety of machinery – Safety distances to prevent hazard zones.

- API RP 13C:2020 – Recommended Practice for Drilling and Well Servicing Equipment.

- GBT 11648:2012 – Technical specifications for wire mesh products.

- GBT 11650:2012 – Standards for the testing of wire mesh.

Citation:

References to NIST and industry standards are used to ensure the credibility and reliability of the information provided. For further details on standards and measurement practices, visit the NIST website.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025