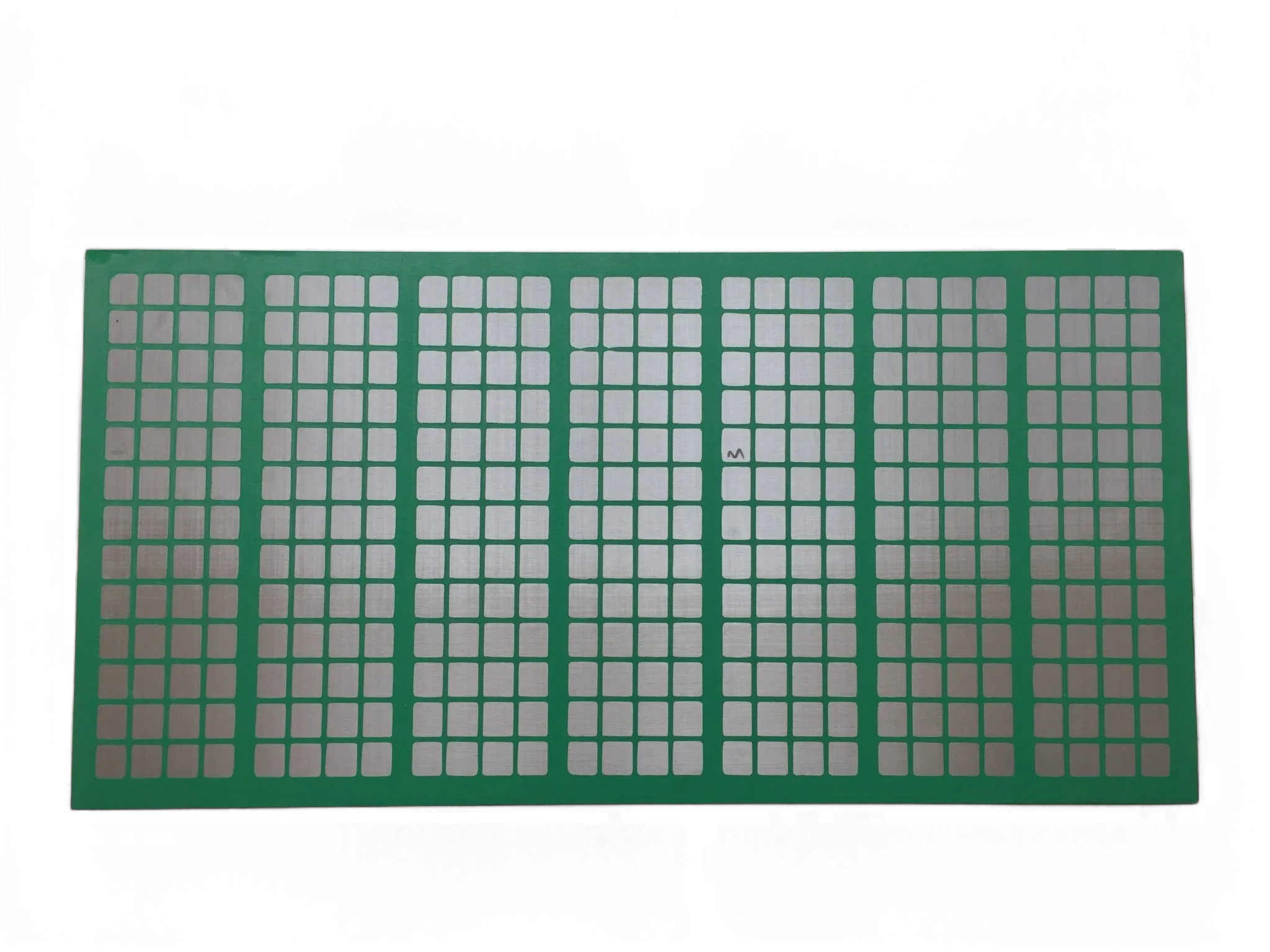

Introduction to Shale Shaker Screens

The Shale Shaker Screen is a critical component in the drilling process, designed to filter and separate drilling cuttings from mud (drilling fluid). This fine mesh, often composed of multiple layers, plays a vital role in maintaining the efficiency and effectiveness of drilling operations. By capturing solid particles and allowing excess mud to drip through, the Shale Shaker Screen ensures that the drilling fluid is recycled, reducing waste and enhancing operational efficiency.

Key Features of Shale Shaker Screens

The Shale Shaker Screen is engineered with several key features that make it indispensable in the drilling industry:

- High Strength and Bearing Capacity: The Shale Shaker Screen is constructed using high-quality stainless steel or carbon steel, ensuring it can withstand the rigorous conditions of drilling operations.

- Good Filtering Accuracy: The multi-layered design of the Shale Shaker Screen allows for precise separation of solids from the drilling fluid, enhancing the overall efficiency of the process.

- Wear and Corrosion Resistance: The Shale Shaker Screen is treated to resist wear and corrosion, ensuring longevity even in harsh environments.

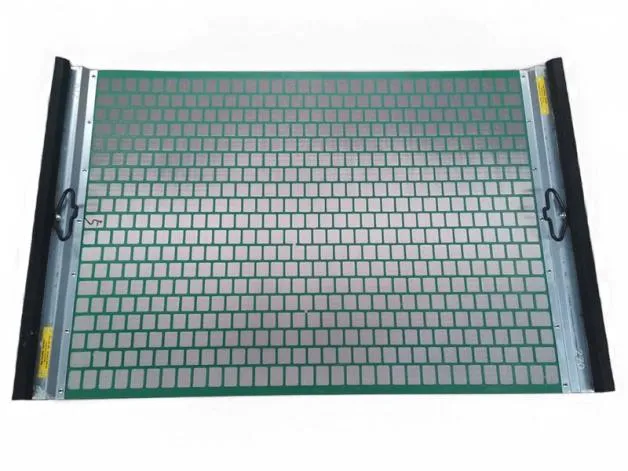

- Flexibility and Adaptability: The Shale Shaker Screen can be customized to fit various shale shaker models, making it a versatile solution for different drilling conditions.

- Easy Installation and Maintenance: Designed for user convenience, the Shale Shaker Screen is easy to install and maintain, reducing downtime and operational costs.

Technical Specifications

| Specification | Details |

|---|---|

| Material | Stainless steel, carbon steel |

| Surface Treatment | Coating |

| Production Process | Weaving and perforating |

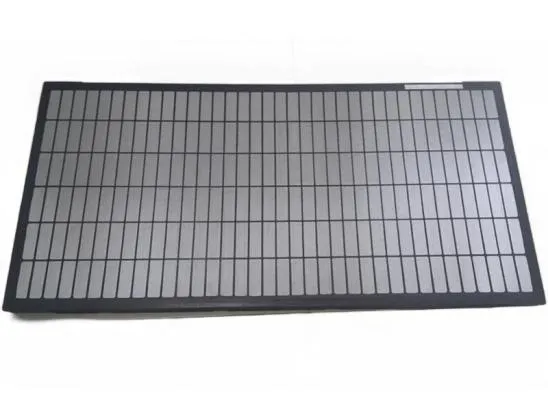

| Color | Black, green, blue (customizable) |

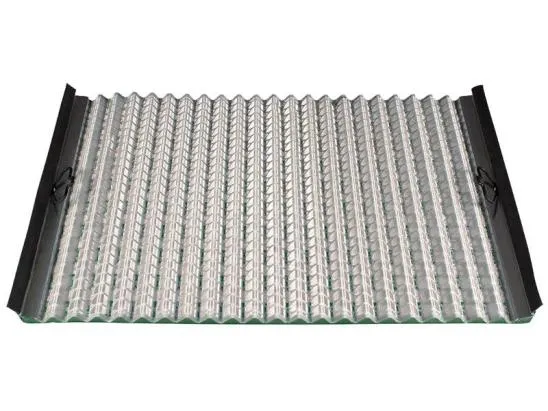

| Type | Steel or composite frame screen, hook strip screen, wave screen |

| Standards | ISO 13501, API RP 13C, GBT 11648, GBT 11650 |

Applications of Shale Shaker Screens

The Shale Shaker Screen is widely used in various industries, including:

- Oil Drilling: Essential for separating cuttings from drilling fluid in oil extraction processes.

- Non-Excavation Horizontal Directional Crossing: Used to purify mud during trenchless drilling operations.

- Coal Bed Methane Drilling: Ensures efficient separation of solids from drilling fluid in coal bed methane extraction.

- Shale Gas Drilling: Critical for maintaining the quality of drilling fluid in shale gas operations.

- Environmental Protection: Applied in river sludge treatment to purify mud and reduce environmental impact.

Company Background: Anping County Hangshun Wire Mesh Manufacture Co., Ltd.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd. is a leading manufacturer of high-quality Shale Shaker Screens. With years of experience in the industry, the company has established itself as a trusted provider of innovative solutions for the drilling and solid control sectors. Their commitment to quality and customer satisfaction has made them a preferred choice for clients worldwide.

The company adheres to strict quality control standards, including NIST and international standards such as ISO 13501 and API RP 13C. This ensures that their products meet the highest levels of performance and reliability. Anping County Hangshun Wire Mesh Manufacture Co., Ltd. is dedicated to continuous improvement and innovation, providing cutting-edge solutions that meet the evolving needs of the drilling industry.

Product Variants and Customization

Anping County Hangshun Wire Mesh Manufacture Co., Ltd. offers a variety of Shale Shaker Screens to suit different drilling conditions and requirements:

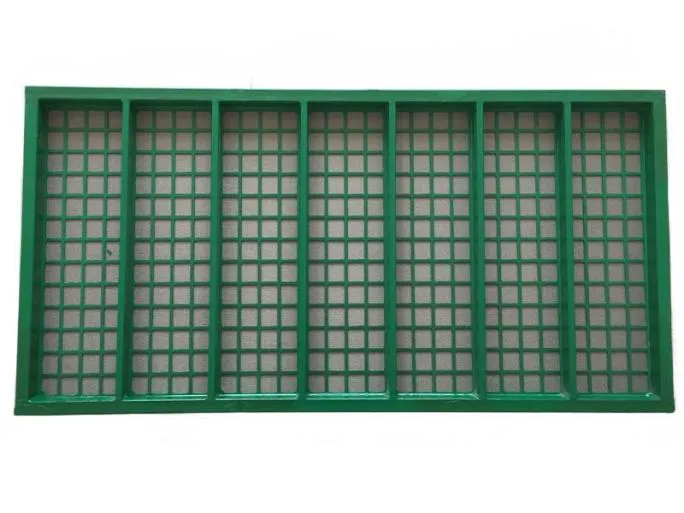

- Steel Frame Shale Shaker Screen: Known for its high load-bearing capacity, ideal for heavy-duty drilling operations.

- Composite Frame Shale Shaker Screen: Combines the benefits of different materials for enhanced performance and durability.

- Hook Strip Shale Shaker Screen: Designed for easy installation and maintenance, providing flexibility in various drilling environments.

- Wave Shale Shaker Screen: Offers the best processing efficiency, making it a popular choice for demanding applications.

The company also provides customization options, allowing clients to specify colors, dimensions, and other requirements to meet their unique needs. This level of flexibility ensures that the Shale Shaker Screen is perfectly suited for each application.

Why Choose Anping County Hangshun Wire Mesh Manufacture Co., Ltd.?

Choosing Anping County Hangshun Wire Mesh Manufacture Co., Ltd. for your Shale Shaker Screen needs offers several advantages:

- Quality Assurance: The company's products are manufactured to meet international standards, ensuring reliability and performance.

- Expertise and Experience: With years of experience in the industry, the company has developed a deep understanding of drilling operations and the specific requirements of the market.

- Customer-Centric Approach: Anping County Hangshun Wire Mesh Manufacture Co., Ltd. prioritizes customer satisfaction, offering personalized solutions and exceptional service.

- Comprehensive Support: From initial consultation to after-sales support, the company provides end-to-end assistance to ensure customer success.

Conclusion

The Shale Shaker Screen is an essential component in the drilling industry, offering efficient and reliable solutions for separating solids from drilling fluid. Anping County Hangshun Wire Mesh Manufacture Co., Ltd. stands out as a leading provider of high-quality Shale Shaker Screens, combining advanced technology, strict quality control, and customer-centric services to meet the diverse needs of the market. Whether you are involved in oil drilling, coal bed methane extraction, or environmental protection, the Shale Shaker Screen from Anping County Hangshun Wire Mesh Manufacture Co., Ltd. is the ideal choice for optimal performance and durability.

References

Standards and Citations:

- National Institute of Standards and Technology (NIST): NIST provides authoritative standards and guidelines for various industries, including drilling and solid control systems.

- ISO 13501: This standard outlines the requirements for the design and testing of shale shaker screens.

- API RP 13C: Recommended Practice for Drilling Fluids and Solids Control Equipment, which includes guidelines for shale shaker screens.

- GBT 11648 and GBT 11650: Chinese national standards that specify the technical requirements for shale shaker screens.