- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Exploring the Different Types and Uses of Shaker Screens in Industry

Understanding Shaker Screens Essential Tools in the Industry

Shaker screens, often referred to as vibrating screens or shale shakers, are crucial components in various industries, particularly in oil and gas drilling, mining, and construction. These specialized screens are designed to separate solids from liquids, facilitating the efficient management of drilling mud and enhancing the overall operational efficiency of processes.

What are Shaker Screens?

Shaker screens are mechanical devices used to filter and separate materials. In the context of oil and gas drilling, they play a vital role in the initial phase of the drilling process, where drilling mud circulates through the borehole. The screens are mounted on shakers, and as the mud passes through them, they effectively remove cuttings and other solid particles from the mixture, allowing for clearer fluid to be reused in the drilling operation.

Types of Shaker Screens

There are several types of shaker screens, each designed for specific applications and materials. The most common types include

1. Flat Screens These are simple, flat panels that can be made from various materials, including polyurethane, steel, or woven wire cloth. They are effective for separating larger particles but may not be suitable for finer materials.

2. Pyramid Screens Featuring a pyramid-like design, these screens provide more surface area and improved stratification of materials. This design optimizes fluid flow and increases the efficiency of solid-liquid separation.

3. Dewatering Screens These specialized screens are designed to remove excess water from the solid materials, making them invaluable in applications such as mining or wastewater management.

4. Composite Screens Combining elements of different materials, composite screens offer enhanced durability and resistance to wear and tear, making them ideal for challenging environments.

Applications in Industry

shaker screens

In the oil and gas industry, shaker screens are used extensively during the drilling process. The removal of cuttings helps maintain the viscosity of the drilling fluid, ensuring that it can effectively cool and lubricate the drill bit while also carrying away extracted rock and soil. Without efficient shaker screens, cuttings could accumulate, potentially leading to costly operational delays and equipment damage.

In mining, shaker screens are employed to separate valuable minerals from waste rock

. The efficiency and effectiveness of these screens can significantly impact the overall yield and profitability of a mining operation. Similarly, in the construction industry, shaker screens are used to sift through materials, ensuring that only the desired sizes are used for specific applications.Benefits of Using Shaker Screens

The primary benefits of using shaker screens in various industries include

- Increased Efficiency By quickly separating solids from liquids, shaker screens enable continuous flow processes, minimizing downtime.

- Cost-Effectiveness Efficient separation reduces the need for additional filtration systems and allows for the recycling of fluids, which can considerably lower operational costs.

- Enhanced Safety By effectively filtering out solids, shaker screens contribute to a safer work environment, reducing the risk of equipment failure and related accidents.

- Environmental Protection Many industries face strict regulations regarding waste management. Shaker screens help reduce waste and ensure compliance with environmental standards by allowing for the recycling of drilling fluids and other materials.

Conclusion

Shaker screens are indispensable tools in the oil and gas, mining, and construction industries. Their ability to efficiently separate solids from liquids not only enhances operational performance but also contributes to safety and environmental compliance. As technology continues to advance, we can expect further innovations in shaker screen designs and materials, leading to even greater efficiencies in industrial processes. Understanding the role and benefits of shaker screens is essential for any industry professional looking to optimize operations and ensure sustainable practices.

-

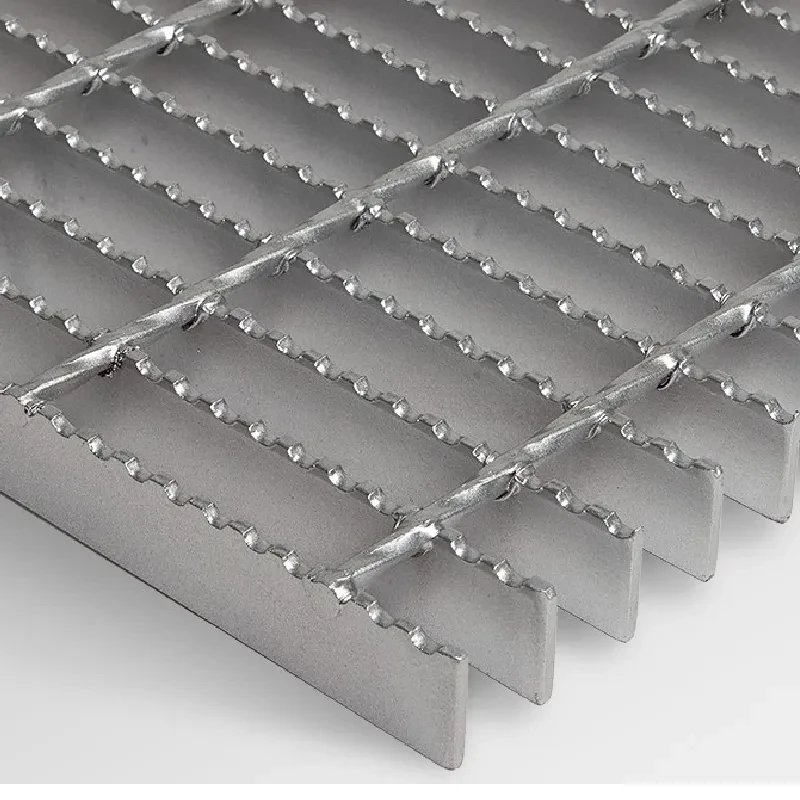

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025