- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Design and Functionality of Shaker Screens in Industrial Applications

Understanding Shaker Screens A Crucial Component in the Mining and Oil Industries

Shaker screens, also known as drilling screens or vibrating screens, play a vital role in the mining, oil, and gas industries. These devices are essential for separating valuable materials from unwanted substances, ensuring the efficiency and effectiveness of the extraction process. As industries continue to evolve, understanding the importance of shaker screens and their operational mechanics becomes increasingly important.

Shaker screens are primarily used in drilling operations, particularly in the extraction of oil and gas from underground reservoirs. The fundamental purpose of these screens is to filter drilling fluid, also known as mud, which is circulated during the drilling process. The mud serves several functions it cools the drill bit, carries drilled solids back to the surface, and helps prevent well blowouts. However, this mud also collects solid particles, such as rock cuttings, which need to be separated to maintain the drilling efficiency.

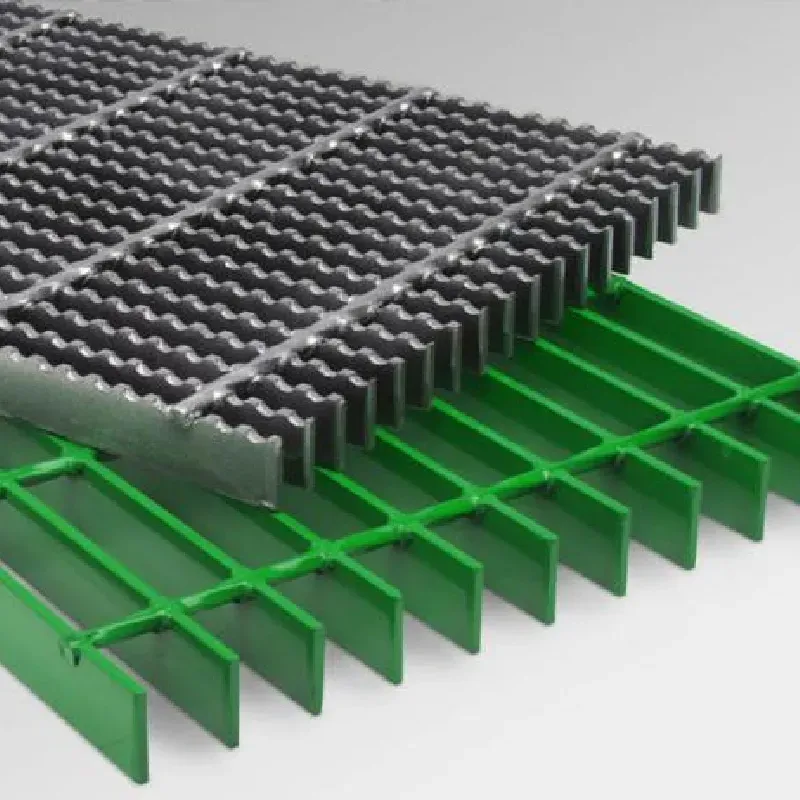

The design of shaker screens is simple yet effective. Essentially, they consist of a frame with a mesh surface that is mounted on a vibrating mechanism. As the drilling fluid flows across the screen, the vibration aids in the separation process. Smaller particles pass through the mesh, while larger debris is discharged, allowing for the recycling of drilling fluids and the recovery of valuable minerals. This process not only improves efficiency but also minimizes waste, making it environmentally friendly.

shaker screens

Different types of shaker screens are available, each designed for specific applications and materials. The most common types include flat screens, pyramid screens, and composite screens. Flat screens are versatile and used for general purposes, while pyramid screens offer enhanced performance for finer materials. Composite screens, made from a combination of materials, provide durability and resistance to wear. The choice of screen type depends on factors like the type of drilling fluid used, the size of particles being filtered, and the specific requirements of the drilling site.

Maintenance of shaker screens is critical for ensuring their longevity and effectiveness. Regular inspection and cleaning can prevent blockages and prolong the service life of the equipment. Operators are trained to monitor the performance of shaker screens and to replace them as needed to maintain optimal efficiency. A well-maintained shaker screen not only improves the overall productivity of the drilling operation but also contributes to safety by preventing potential equipment failures.

The importance of shaker screens extends beyond just the oil and gas sectors. In mining applications, shaker screens are employed to separate ores from waste material during the processing stages. This ensures that the extraction operations are not only efficient but also cost-effective. Industries that require material classification, such as construction and recycling, also rely on shaker screens for their ability to handle various materials and improve production processes.

In conclusion, shaker screens are indispensable tools in the mining and oil sectors, playing a critical role in the extraction and processing of resources. Their design and operational mechanics greatly influence the efficiency of drilling operations, leading to significant cost savings and reduced environmental impact. As technology advances, the development of more efficient and effective shaker screens will continue to shape the future of these industries, promoting sustainable practices and economic viability. Understanding and investing in shaker screen technology will undoubtedly remain a priority for industry operators looking to optimize their processes and minimize waste.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025