- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

shaker screen mesh

Understanding Shaker Screen Mesh A Vital Component in Drilling Operations

In the realm of drilling operations, whether in the oil and gas industry or the mining sector, the shaker screen mesh is an essential component that plays a pivotal role in separating solids from liquids. Rendered in various materials and designs, shaker screen mesh is vital for enhancing the efficiency and effectiveness of the drilling process.

At its core, a shaker screen mesh is a filter designed to classify drilled cuttings and facilitate the recycling of drilling fluids. These screens are mounted on shale shakers, which are the first stage of the separation process. Upon drilling, the mixture of drilling fluid and rock cuttings is transported to the shaker, where the mesh screens allow the liquid to pass while retaining the solids.

The design and material composition of the mesh are significant factors that influence the performance of the shale shaker. Typically crafted from stainless steel or polyester, shaker screens come in various mesh sizes, typically ranging from 20 to 400 mesh. The choice of mesh size depends on the specific requirements of the drilling operation, with coarser meshes better suited for handling larger solids while finer meshes are effective for silt and clay removal.

One of the primary advantages of using shaker screen mesh is its ability to enhance drilling efficiency. By separating the cuttings from the drilling fluids, operators can recycle and reuse the fluids, which reduces operational costs and environmental impact. This, in turn, leads to a more sustainable drilling operation. Additionally, efficient solids control allows for better wellbore stability, reducing the likelihood of complications such as stuck pipe or formation damage.

shaker screen mesh

It's also important to consider the wear and tear associated with shaker screens. Given that drilling environments are often harsh—with abrasive materials and corrosive fluids—high-quality shaker screens are designed for durability and longevity. Operators must select screens that match the conditions of their particular drilling project to optimize their performance and reduce downtime due to replacements.

Furthermore, advancements in technology have led to the evolution of shaker screen mesh designs. Recent innovations include composite screens, which offer a combination of the benefits of traditional mesh and enhanced durability. These screens can often withstand higher flow rates and have improved wear characteristics, contributing even further to operational efficiency.

The selection and maintenance of shaker screens are critical aspects of drilling operations. Regular inspection for wear and tear is essential to ensure optimal performance. Operators should also be aware of the characteristics of the formations they are drilling into, as this knowledge can guide them in choosing the appropriate mesh size.

In conclusion, shaker screen mesh plays a fundamental role in the success of drilling operations by separating solids from liquids and facilitating the recycling of drilling fluids. With its ability to enhance efficiency, reduce costs, and promote sustainability, the significance of this component cannot be overstated. As technology continues to advance, the future of shaker screen design looks promising, leading to even greater efficiencies in drilling practices. Understanding its function, benefits, and maintenance can greatly improve overall drilling operations and contribute to more sustainable practices in the industry.

-

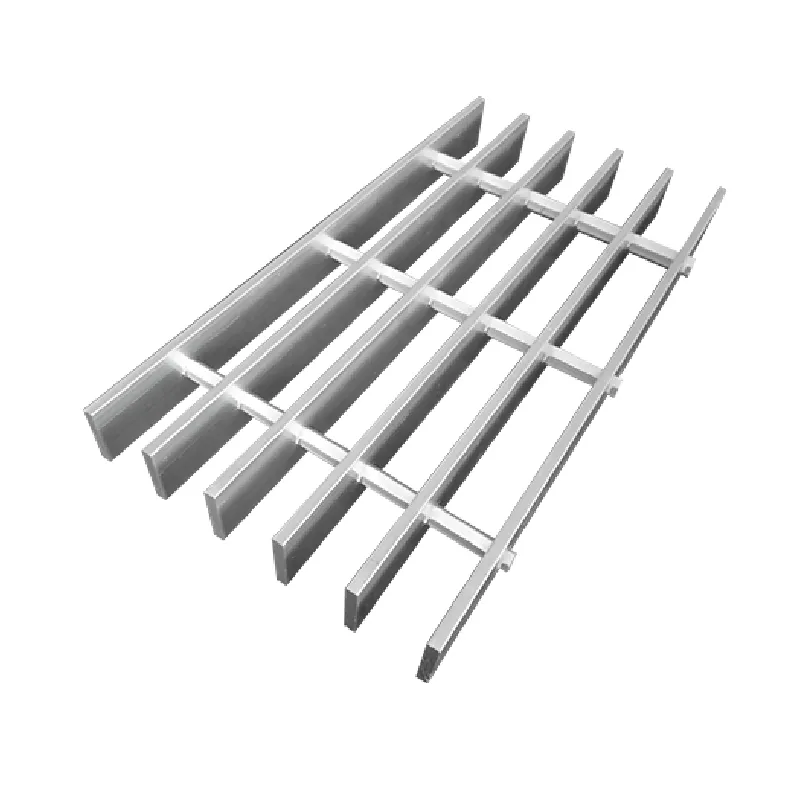

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025