- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

shaker screen manufacturers

Shaker Screen Manufacturers Pioneering the Future of Separation Technology

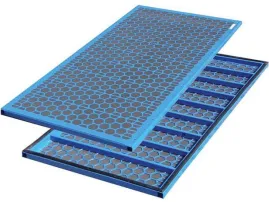

In the world of industrial processes, the importance of separation technology cannot be overstated. Among the various tools and equipment employed in these processes, shaker screens play a crucial role in efficiently separating materials based on size and density. As industries expand, the demand for high-quality shaker screens has surged, leading to the emergence of numerous shaker screen manufacturers. This article explores the significance of shaker screen manufacturers, their contributions to various industries, and what sets them apart in today’s competitive market.

Understanding Shaker Screens

Shaker screens, also known as vibrating screens, are essential components used to separate and classify materials in numerous industrial applications. They function by utilizing a rapid, oscillating motion that allows particles to pass through perforated surfaces or mesh, enabling the efficient sorting of materials. Common industries that rely on shaker screens include mining, drilling, recycling, and food processing. Each industry has specific requirements regarding the type of shaker screen needed, which emphasizes the necessity for a diverse range of manufacturers capable of meeting these varying demands.

The Role of Shaker Screen Manufacturers

Shaker screen manufacturers play a pivotal role in providing tailored solutions that enhance productivity and efficiency in industrial processes. These manufacturers design and produce a wide variety of shaker screens made from different materials such as stainless steel, carbon steel, and polyurethane. The choice of material impacts the durability, weight, and resistance of the screen to various environmental factors, including temperature variations and chemical exposure.

Moreover, shaker screen manufacturers invest in research and development to innovate and improve their products continually. This commitment to innovation ensures that their screens can adapt to the changing needs of industries, such as increased automation and advancements in material science. Manufacturers also provide custom solutions, allowing clients to integrate shaker screens that align perfectly with their specific operational needs.

Key Features of Reliable Shaker Screen Manufacturers

1. Quality Assurance A hallmark of any reputable shaker screen manufacturer is their commitment to quality. This includes rigorous testing of materials and production processes to meet or exceed industry standards. High-quality shaker screens not only enhance operational efficiency but also reduce the frequency of maintenance and replacement, leading to cost savings in the long run.

shaker screen manufacturers

2. Diverse Product Range The best manufacturers offer a comprehensive selection of shaker screens, catering to various applications. Whether clients require flat screens for linear motion vibrating screens or hooked screens for circular applications, a versatile product range signifies a manufacturer’s ability to adapt to market needs.

3. Technical Expertise Shaker screen manufacturers with robust technical knowledge can provide valuable insights and recommendations for clients. This expertise often translates into better product design and selection, ensuring optimal performance in specific applications.

4. Customer Support Strong customer support is essential in the manufacturing landscape. Established manufacturers offer installation, maintenance, and troubleshooting assistance, helping clients maximize the lifetime and effectiveness of their shaker screens.

The Future of Shaker Screen Manufacturing

As industries continue to evolve, shaker screen manufacturers are at the forefront of developing solutions that cater to modern industrial challenges. Trends such as sustainability and eco-friendliness are becoming increasingly significant in manufacturing processes. This shift encourages manufacturers to explore sustainable materials and methods, thereby reducing their environmental impact.

Furthermore, the integration of digital technologies—including IoT and AI—into shaker screen operations is on the rise. These advancements not only enhance monitoring capabilities but also enable predictive maintenance, allowing manufacturers and clients to minimize downtime and optimize performance.

Conclusion

Shaker screen manufacturers are essential partners in the world of industrial separation technology. Their ongoing commitment to quality, innovation, and customer service positions them as leaders in a dynamic labor market. As industries continue to expand and embrace new technologies, these manufacturers will undoubtedly play a crucial role in shaping the future of separation technology, ensuring that the needs of diverse industries are met with excellence and precision.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025