- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shaker Screen for Sale | Durable, OEM Fit, Fast Shipping

shaker screen for sale is a key solution in the Oil and Gas industry, specifically within Oil and gas exploration and production services and equipment and Drilling solid control equipment and accessories. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- shaker screen for sale Overview

- Benefits & Use Cases of shaker screen for sale in Drilling solid control equipment and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Oil and Gas

- Conclusion on shaker screen for sale from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

shaker screen for sale Overview

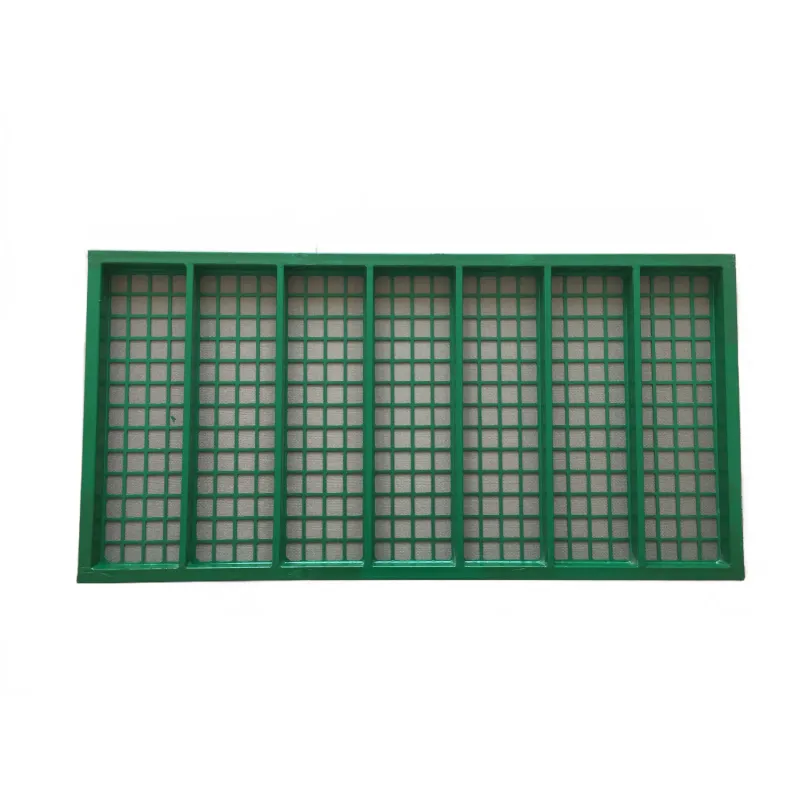

In drilling operations, the shale shaker is the first line of defense in solids control—and the screen is its critical wear part. A high-quality shaker screen separates cuttings from drilling fluids, safeguarding mud properties, reducing dilution costs, and protecting downstream equipment like desanders and centrifuges. An industrial shaker screen must balance open area, conductance, and mechanical strength to deliver consistent cut and long field life across both WBM and OBM. Anping County Hangshun Wire Mesh Manufacture Co., Ltd provides steel-frame shale shaker screens engineered for demanding rigs, with tight mesh tolerances and robust bonding for reliable performance.

- The product: steel-frame, pre-tensioned shale shaker screens with multi-layer stainless steel wire mesh (304/316) bonded to a reinforced steel support grid; optional repair plugs extend lifecycles.

- Technical notes: API RP 13C-compliant labeling, wide API mesh range (approx. API 20–325), optimized open area for higher conductance, strong perimeter sealing to minimize fluid bypass.

- Case insight: Operators using Hangshun’s steel-frame screens report fewer changeouts per well section and more stable cuttings dryness during high-ROP intervals compared with generic options.

- Manufacturer: As one of the experienced shaker screen manufacturers in Anping—China’s wire mesh hub—Hangshun leverages precision weaving, automated bonding, and 100% visual inspection to ensure consistency lot-to-lot.

Benefits & Use Cases of shaker screen for sale in Drilling solid control equipment and accessories

From spud mud to production hole sections, the right shaker screen selection (mesh count and layering) dictates how effectively solids are removed while preserving rheology. Hangshun’s industrial shaker screen lineup serves onshore and offshore rigs, batch drilling, geothermal, and workover applications. Typical use cases include high-solids surface sections (coarser API sizes), directional drilling in reactive shales (balanced capacity and cut), and fine control in reservoir sections (finer API sizes to protect fluid loss control agents).

- Key features: durable steel frame, optimized mesh layering for throughput and cut-point accuracy, robust bonding for vibration resistance, and effective side/perimeter seals to minimize bypass.

- Competitive advantages: consistent API RP 13C labeling for predictable performance, broad compatibility with common shaker dimensions, fast delivery, and engineered open area to improve conductance without sacrificing integrity.

- Operational benefits: improved cuttings dryness, reduced mud losses, fewer unplanned screen changes, and better protection of downstream solids control assets—all translating to a lower cost per foot drilled.

- Sector expertise: Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports drilling contractors and service companies with technical selection guidance, stocking strategies, and custom screen sizes on request.

Cost, Maintenance & User Experience

Total cost of ownership for shaker screens extends beyond unit price. The real savings come from longer life, stable conductance, fewer trips to the shaker house, and decreased mud dilution. Hangshun’s steel-frame design resists warping and delamination under high G-loading, helping teams avoid premature failures. B2B users note dependable fit-up and sealing, reducing fluid bypass that erodes ROI. For procurement, dependable lead times and consistent quality reduce inventory buffers and stockout risk across multi-rig fleets.

- Durability & ROI: Reinforced support grid, strong bonding, and quality mesh deliver longer on-rig service life; repair plugs address minor tears to extend usable hours.

- Maintenance best practices: store screens flat and dry; inspect for edge wear and tears at every connection; match API size to formation/ROP; avoid high-pressure direct spraying to protect the mesh weave.

- User feedback: drilling superintendents value predictable API labeling, quick installation, and stable performance in both WBM and OBM—particularly during high-flow, high-solids transients.

Sustainability & Market Trends in Oil and Gas

Solids control is central to both performance and environmental stewardship. Effective screening lowers dilution, reduces waste volumes, and helps keep fluids within specification—supporting compliance and ESG goals. Market trends include higher throughput requirements, tighter cut-points in challenging formations, and procurement strategies that emphasize lifecycle impacts over unit cost. Steel-frame screens remain a strong choice for recyclability and structural rigidity, while ongoing material and bonding innovations enhance service life.

- Sustainability angle: longer-lasting screens mean fewer disposals and less packaging waste; improved dryness lowers transport and treatment costs for cuttings.

- Forward-looking stance: Anping County Hangshun Wire Mesh Manufacture Co., Ltd invests in precision weaving, process control, and material selection to extend screen life and reduce waste—helping operators align procurement with HSE and cost objectives.

Conclusion on shaker screen for sale from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

For B2B decision-makers seeking a dependable shaker screen for sale, Hangshun’s steel-frame designs deliver the balance of capacity, cut-point accuracy, and durability demanded by modern drilling programs. As experienced shaker screen manufacturers, the company pairs quality-controlled production with responsive support—helping fleets lower TCO and protect mud systems across wells and basins.

- Value recap: robust steel-frame construction, consistent API RP 13C labeling, reliable sealing and fit, and strong lifecycle economics for solids control operations.

- Reputation: Anping County Hangshun Wire Mesh Manufacture Co., Ltd is a trusted partner for industrial shaker screen supply, customization, and technical selection support.

- Strong CTA: Contact us: email: sales@hfpetromesh.com — Visit our website: https://www.hfpetromesh.com — Product page: Steel-Frame Shale Shaker Screen

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025