- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

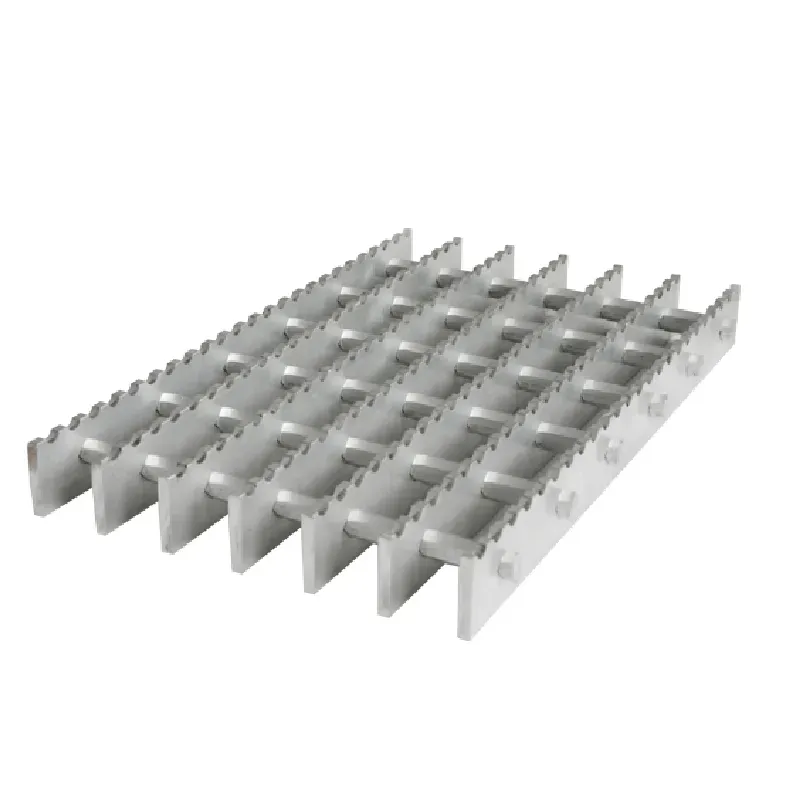

Serrated Edge Gratings for Enhanced Light Manipulation and Diffraction Efficiency

Serrated Type Grating An Overview

Serrated type gratings represent an innovative advancement in the field of optical components, particularly in the manipulation of light. These unique structures are characterized by their distinct serrated edges, which play a crucial role in their functioning and enhance their performance in various applications.

At its core, a serrated grating comprises a surface with a series of grooves or teeth that create a pattern reminiscent of a saw blade. This serration adds complexity to the way light interacts with the grating. When light waves strike the serrated surface, they undergo diffraction. The serrations enable the grating to diffract light at different angles, depending on the wavelength of the light. This property is particularly valuable in spectroscopy, where the ability to separate different wavelengths of light is essential for analysis.

One of the primary benefits of serrated type gratings is their high efficiency

. Compared to traditional smooth gratings, serrated gratings can achieve greater diffraction efficiency due to their enhanced surface area and the ability to redirect more light. This is particularly important in applications where maximum light capture is necessary, such as in telecommunications and laser systems.serrated type grating

Moreover, serrated gratings can be designed to provide specific dispersion characteristics. By altering the angle, depth, and spacing of the serrations, engineers can fine-tune the grating to achieve desired optical properties. This customization makes serrated gratings highly versatile, catering to a range of wavelengths from ultraviolet to infrared. Their adaptability also extends to different applications, including imaging systems, sensors, and spectrometers.

In addition to optical performance, serrated type gratings offer advantages in terms of durability and robustness. The serrated design can enhance the mechanical strength of the grating, making it less susceptible to damage. This durability is vital in harsh environments where traditional optical components might fail.

However, the design and manufacturing of serrated gratings come with their own set of challenges. The precision required to create the serrated patterns necessitates advanced fabrication techniques. Modern methods, such as electron beam lithography and laser ablation, have made it possible to produce high-quality serrated gratings with intricate designs. The research into improving these fabrication techniques continues to evolve, opening the door for more complex and efficient grating structures.

In summary, serrated type gratings are a significant development in optical engineering, offering enhanced efficiency, customizable dispersion properties, and durability. Their ability to manipulate light makes them invaluable in various scientific and industrial applications. As advancements in fabrication technologies progress, the potential for serrated gratings to contribute to innovative optical systems will undoubtedly grow, paving the way for new discoveries and applications in the realm of photonics.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025