- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

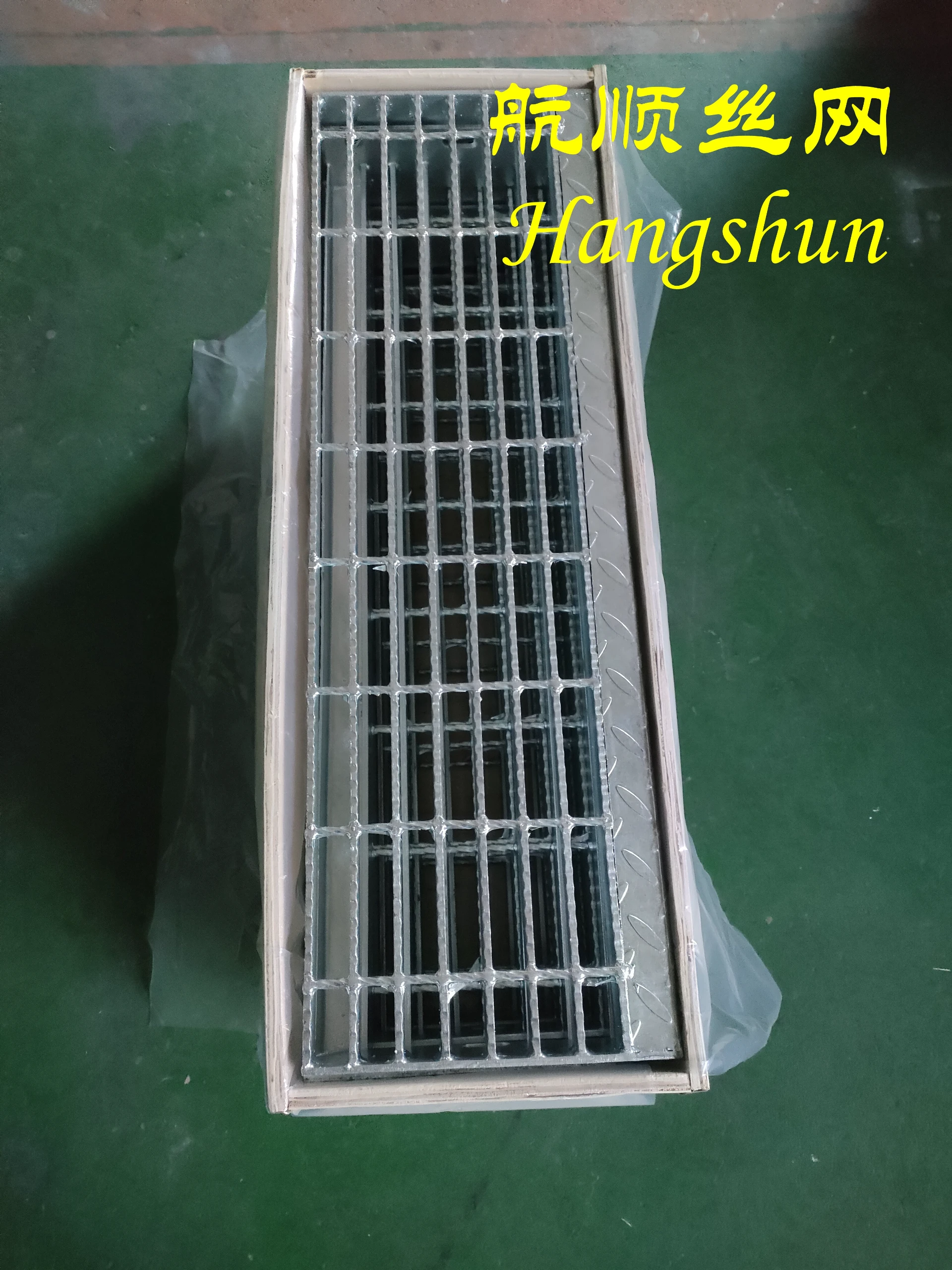

serrated steel flat bar

Understanding Serrated Steel Flat Bars Applications, Benefits, and Manufacturing

Serrated steel flat bars are a specialized steel product that has gained traction across various industries due to their unique features and applications. Characterized by a serrated edge, these flat bars offer enhanced grip and structural stability, making them an excellent choice for a wide range of projects. In this article, we will delve into the characteristics of serrated steel flat bars, their benefits, applications, and the manufacturing process that ensures their quality and effectiveness.

Characteristics of Serrated Steel Flat Bars

Serrated steel flat bars are typically made from high-quality carbon steel or stainless steel, which ensures durability and resilience. The serration, or the patterned grooves, along the edge of the flat bar provides a non-slip surface, making it an ideal choice for safety applications. These bars come in various dimensions and can be cut to specific lengths, allowing for versatility in their usage. The serrations can be customized in depth and pattern, depending on the intended application.

Benefits of Serrated Steel Flat Bars

One of the primary advantages of serrated steel flat bars is their enhanced grip. The serrated surface increases friction, reducing the risk of sliding or movement, especially in environments where safety and stability are paramount. This feature makes them particularly useful in construction, scaffolding, and floor applications where workers are at risk of slipping.

Additionally, serrated flat bars offer improved weight distribution characteristics. The design allows them to bear heavier loads without warping or bending, an essential property for structural applications. This makes them suitable not only for pedestrian walkways but also for industrial settings where heavy machinery and equipment are present.

Another benefit is their resistance to wear and tear. Due to their steel composition, serrated flat bars can withstand harsh weather conditions, chemical exposure, and impact, maintaining their integrity over time. This durability translates to lower maintenance costs and longer-lasting installations, ultimately providing a better return on investment.

Applications of Serrated Steel Flat Bars

Serrated steel flat bars are widely used across various industries, due to their versatility and functional advantages. Some common applications include

serrated steel flat bar

1. Construction Serrated flat bars serve as an essential component in scaffolding systems, providing a stable and secure platform for workers at various heights. Their non-slip surface is crucial in high-stakes construction environments.

2. Walkways and Platforms They are often used to create outdoor walkways, platforms, and stairs where additional grip is needed. The serrated edges help prevent accidents, ensuring safety for pedestrians.

3. Ramps In the manufacturing industry, serrated flat bars are frequently utilized for constructing ramps. Their sturdy structure and non-slip properties allow for the safe movement of materials and equipment.

4. Industrial Equipment These bars can be found in various machines and equipment where a secure gripping surface is required, ensuring safe operation within factories and warehouses.

5. Railings and Fencing Serrated steel flat bars can also be used in the fabrication of railings and fencing systems, providing added safety with their ability to deter slips and falls.

The Manufacturing Process

The manufacturing of serrated steel flat bars involves several key steps to ensure precision and quality. It typically begins with selecting high-grade steel, which is then heated and formed into flat bars through a process called hot rolling. Once the desired thickness and width are achieved, the serration is added using specialized machines. This can involve stamping or milling the serrated pattern onto the bar’s surface.

Quality control is a critical aspect of the manufacturing process. Each batch of serrated steel flat bars is subjected to rigorous testing to ensure it meets industry standards for strength, durability, and slip resistance. Additionally, the final product can be treated with coatings to enhance corrosion resistance, making them suitable for outdoor applications.

Conclusion

Serrated steel flat bars represent an essential element in modern safety and construction applications. Combining durability, non-slip capabilities, and structural integrity, these products are ideal for various industrial contexts. As industries continue to prioritize safety and efficiency, serrated steel flat bars will undoubtedly remain a vital component in their operations. Their adaptability and effectiveness make them a worthwhile investment for businesses looking to enhance safety and performance in their projects.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025