- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

serrated grating weight

Understanding Serrated Grating Weight An Overview

Serrated grating, a crucial component in various engineering and architectural applications, serves a multitude of purposes ranging from safety to aesthetic appeal. The weight of a serrated grating is an important consideration in both the design and installation phases. In this article, we will delve into what serrated grating is, the factors influencing its weight, its applications, and why understanding its weight is vital for engineers and architects.

What is Serrated Grating?

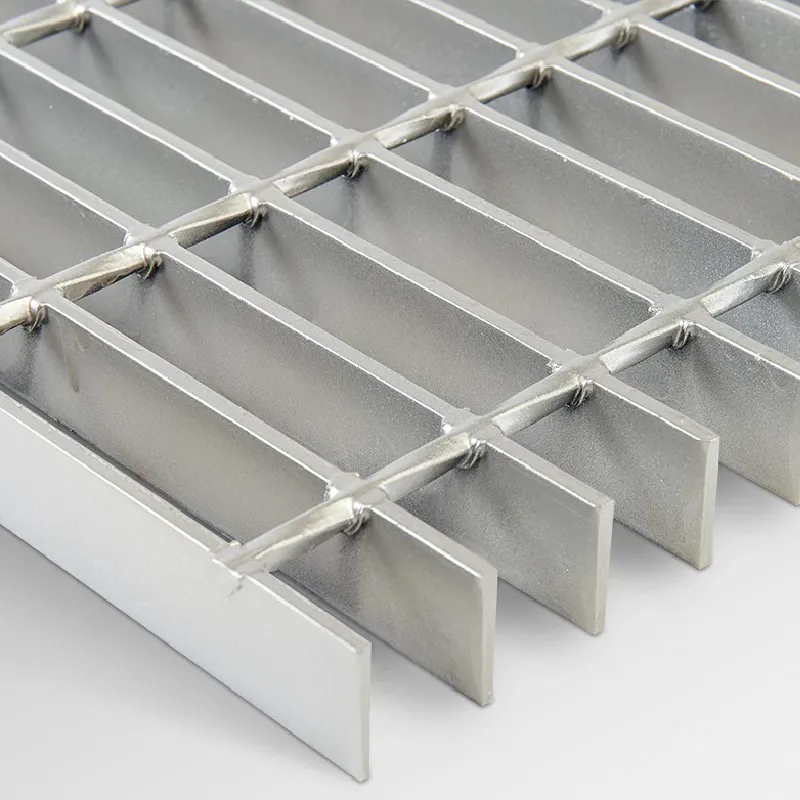

Serrated grating is a type of flooring or platform system made from metal (often steel or aluminum) that features a serrated or notched surface. This design improves traction and prevents slipping, making it ideal for industrial environments where safety is paramount. Serrated gratings come in various sizes and shapes, tailored to meet specific load-bearing requirements and environmental challenges.

Factors Affecting Serrated Grating Weight

The weight of serrated grating is influenced by several factors, including material type, dimensions, and design features

1. Material The choice of material significantly impacts weight. For instance, steel serrated gratings are heavier than aluminum variants due to the difference in material density. While steel is often chosen for its durability and strength, aluminum is preferred for its lightweight nature and corrosion resistance.

2. Thickness The thickness of the grating directly correlates with its weight. Thicker grates provide better load resistance but also increase overall weight. Designers must balance the required strength with practicality in terms of weight.

3. Dimensions The width and length of the serrated grating also contribute to its weight. Larger gratings will, understandably, be heavier. Architectural and industrial design constraints may dictate the dimensions of the grating, affecting the overall weight.

4. Serration Pattern The specific design of the serration can influence both weight and functionality. Different patterns may create variations in material usage, thereby affecting weight while also providing various levels of slip resistance.

Applications of Serrated Grating

Serrated gratings are used in a variety of settings

serrated grating weight

- Industrial Flooring In factories and warehouses, where heavy machinery operates, serrated grating provides a safe surface for workers.

- Walkways and Platforms Exposed outdoor areas frequently utilize serrated grating to ensure safe passage, especially in wet conditions.

- Mezzanines Many industrial buildings feature serrated gratings in their mezzanine levels to provide a sturdy and safe walking surface.

- Staircases The anti-slip feature of serrated grates also makes them ideal for stair treads in both public and private buildings.

Importance of Understanding Grating Weight

Understanding the weight of serrated grating is crucial for several reasons

- Load-Bearing Calculations Engineers must ensure that the supporting structures can handle the weight of the grating, especially in multi-story applications.

- Transportation and Installation Knowing the weight can help in planning the logistics of transporting the grating to the installation site and determining how many workers or what equipment will be needed to safely handle the material.

- Safety Compliance In many jurisdictions, building codes require that materials used in construction meet specific weight-bearing standards to prevent accidents. Ensuring that serrated grating complies with these regulations is essential.

- Cost Efficiency By understanding the weight and material properties, architects and engineers can make more informed decisions, potentially reducing unnecessary costs.

Conclusion

In summary, serrated grating is an essential element in numerous applications where safety and functionality converge. The weight of these gratings, influenced by various factors including material, thickness, and dimensions, must be carefully considered by engineers and architects. This understanding ensures that serrated gratings are not only effective in providing safety and durability but also align with compliance regulations, transportation logistics, and cost management. As industries continue to evolve, the significance of serrated grating and its weight will undoubtedly remain a focal point in engineering design and implementation.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025