- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

serrated grating sizes

Understanding Serrated Grating Sizes A Comprehensive Overview

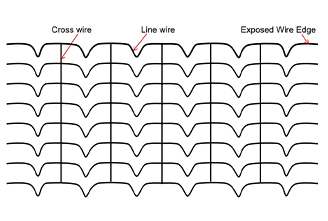

Serrated gratings, often used in various engineering and architectural applications, are designed with a series of notches or serrations along their surface. These unique features allow for improved functionality, particularly in terms of slip resistance and visual appeal. As industries shift towards safety and aesthetics, the importance of understanding serrated grating sizes becomes crucial.

First and foremost, the dimensions of serrated gratings are vital in determining their effectiveness. The size of the serrations, typically measured in millimeters or inches, directly impacts the grip surface. Smaller serrations may be ideal for less demanding environments, where minimal slip resistance is needed. In contrast, larger serrations are better suited for high-traffic areas or environments with increased risk of slips and falls. Various specifications help determine the appropriate sizing for specific applications, from stair treads to walkways.

Moreover, material selection plays a significant role in the performance of serrated gratings. Common materials include steel, aluminum, and fiberglass. Each material can be manufactured with different serration sizes, affecting their overall weight, durability, and maintenance requirements. For instance, steel gratings with larger serrations provide excellent traction and are often used in construction sites or outdoor areas exposed to the elements. On the other hand, fiberglass options may offer lightweight alternatives while still maintaining adequate traction.

serrated grating sizes

Another critical consideration when discussing serrated grating sizes is load-bearing capacity. The spacing between the serrations and their height will influence how much weight the grating can support without bending or breaking. Industries such as transportation, manufacturing, and construction need to carefully calculate the required load capacity based on the intended application. Thus, selecting the correct serrated grating size is fundamental to ensuring safety and durability.

In addition to functionality, aesthetics should not be overlooked. Serrated gratings can be customized in various sizes and finishes to match architectural designs. This flexibility allows for practical applications in commercial settings while enhancing visual appeal. Designers often incorporate these elements into their projects to achieve both safety and style.

Finally, manufacturers provide guidelines and standardized sizes for serrated gratings, simplifying the selection process. Understanding the specifications and application requirements enables engineers and architects to make informed choices about the appropriate grating size for their projects.

In summary, the significance of serrated grating sizes lies in their ability to provide safety, durability, and aesthetic appeal. As industries evolve, the need for versatile and effective grating solutions will continue to grow, emphasizing the importance of understanding the relevant sizing specifications. By considering dimensions, materials, load capacity, and design, professionals can ensure the successful integration of serrated gratings into their projects.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025