- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

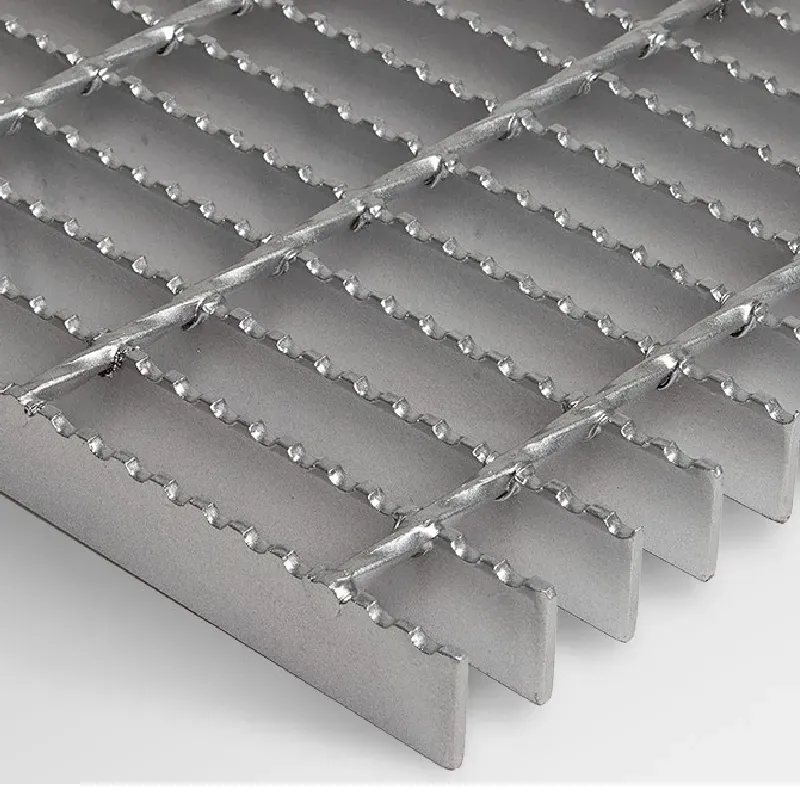

serrated grating sizes

Understanding Serrated Grating Sizes An Overview

Serrated gratings are increasingly recognized in various applications, particularly in fields requiring precise light manipulation and distribution, such as optics, telecommunications, and energy harvesting. A serrated grating consists of a series of parallel grooves or notches that are cut into the surface of a material, forming a patterned structure that can diffract light in specific ways. The size and spacing of these serrations play a crucial role in determining the performance characteristics of the grating.

The Importance of Grating Size

Serrated grating sizes refer to the dimensions of the individual grooves, including their width, depth, and spacing. These parameters directly influence the diffraction efficiency, wavelength selectivity, and angular dispersion of the light. For instance, narrower grooves tend to provide higher diffraction efficiency for shorter wavelengths, while wider grooves are better suited for longer wavelengths. This relationship is essential for applications such as spectroscopy, where accurate wavelength resolution is required.

Moreover, the depth of the serrations is also significant. Deeper grooves might enhance the grating's ability to diffract light, but they could also introduce challenges related to manufacturing precision and structural integrity. This duality indicates that there is a careful balance that engineers and scientists must achieve when designing serrated gratings for specific uses.

Fabrication Techniques

The production of serrated gratings involves various fabrication techniques, including photolithography, diamond turning, and laser engraving. Photolithography is particularly useful for creating intricate patterns on a microscale, making it ideal for applications in nano-optics and photonic devices. Conversely, diamond turning can produce larger, more robust gratings suitable for industrial applications. Selection of the appropriate fabrication method often depends on the intended application and the required precision of the serrations.

serrated grating sizes

As the field of nanotechnology progresses, advances in manufacturing techniques allow for the creation of more sophisticated serrated grating designs. For example, researchers are exploring materials such as graphene and metamaterials, where serrated gratings can be engineered at the atomic level to achieve unprecedented control over light's behavior.

Applications of Serrated Gratings

Serrated gratings are utilized across various applications. In telecommunications, they serve as components in optical filters, enabling the selective transmission of specific wavelengths of light. This function is critical for optical networks that require efficient data transmission over long distances.

In spectroscopy, serrated gratings are invaluable for analyzing the spectral composition of light. By dispersing light into its constituent wavelengths, scientists can glean information about the chemical composition of substances. This capability is essential in fields such as environmental monitoring, medical diagnostics, and materials science.

Energy harvesting technologies also benefit from serrated gratings, particularly in solar cells. By optimizing the structure of the grating, researchers can enhance the absorption of sunlight, thereby increasing the efficiency of photovoltaic systems.

Conclusion

In summary, serrated grating sizes are a fundamental aspect of optical engineering that influences grating performance in multiple applications. Understanding the effects of different dimensions on light behavior is crucial for advancing technologies in optics, telecommunications, and energy harvesting. As research continues in this area, we can anticipate the development of more advanced and efficient serrated gratings that will push the boundaries of what is possible in light manipulation and utilization. These advancements not only promise to enhance existing technologies but also open doors to new applications that can benefit society as a whole.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025