- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

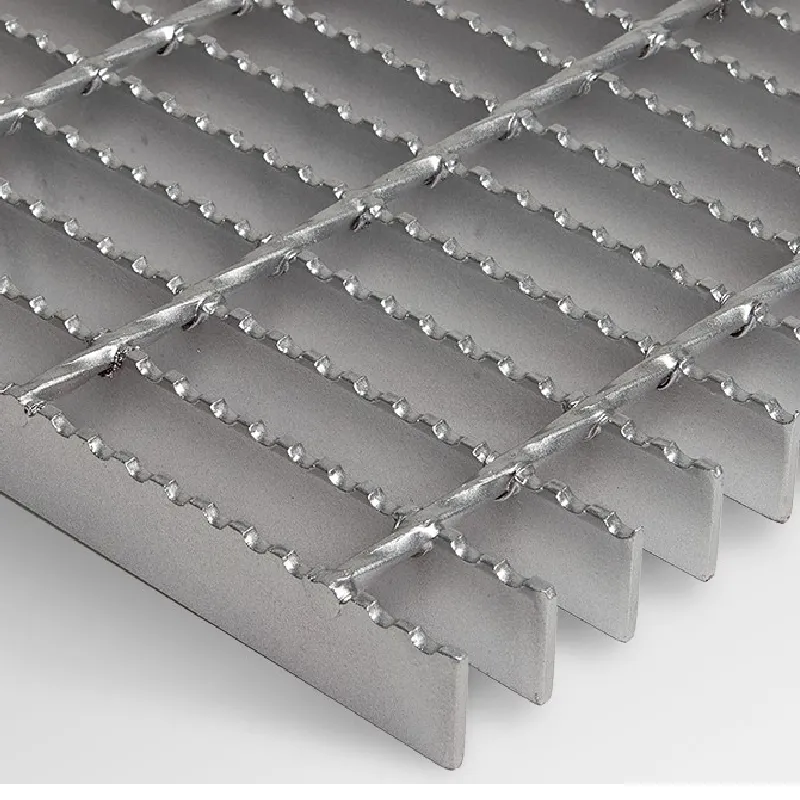

serrated galvanized grating

Serrated Galvanized Grating An Essential Component in Modern Infrastructure

In the realm of industrial applications and construction, safety and functionality are paramount. Among the various materials that contribute to these aspects, serrated galvanized grating has carved a niche for itself due to its unique properties and multifunctional applications. This article delves into the features, benefits, and applications of serrated galvanized grating, demonstrating its significance in contemporary infrastructure.

Understanding Serrated Galvanized Grating

Serrated galvanized grating is a type of metal grating characterized by a series of ridges or serrations along its surface. Typically manufactured from steel, the grating undergoes a galvanization process, where a protective layer of zinc is applied. This not only enhances its corrosion resistance but also prolongs its lifespan, making it ideal for various outdoor and industrial environments.

The combination of serrated surface and galvanized coating presents a perfect solution for areas exposed to moisture, chemicals, and heavy foot traffic. The serration feature provides increased traction, reducing the likelihood of slips and falls—a crucial factor in maintaining workplace safety.

Key Benefits of Serrated Galvanized Grating

1. Enhanced Safety The serrated surface is designed to offer superior grip compared to traditional grating. This is particularly important in environments such as factories, construction sites, and even public walkways, where the risk of slipping can be high.

2. Corrosion Resistance The galvanization process protects steel from rust and deterioration. This is especially beneficial in harsh environments, such as chemical plants or coastal areas, where metal components are more susceptible to the elements.

3. Lightweight Yet Durable Despite its robust nature, serrated galvanized grating remains lightweight, making it easier to handle and install. This characteristic allows for the efficient movement of grating panels, reducing labor costs and installation time.

4. Versatility Serrated galvanized grating can be adapted for a variety of applications—ranging from walkways and platforms to stair treads and drainage covers. Its customizable dimensions and configurations mean that it can fit into numerous designs and specifications.

serrated galvanized grating

5. Easy Maintenance The smooth surface of galvanized grating allows for easy cleaning, which is crucial in maintaining hygiene in environments like food processing plants or pharmaceutical facilities. Regular maintenance is simple, often requiring just a rinse with water or mild detergent.

Applications of Serrated Galvanized Grating

The applications of serrated galvanized grating are extensive and span several industries

- Industrial Facilities Used in power plants, oil refineries, and manufacturing units, serrated grating provides safe walkways for personnel and machinery access.

- Commercial Spaces In shopping malls, airports, and public buildings, serrated grating can be employed in flooring and ramps, ensuring safety and compliance with accessibility standards.

- Transportation It plays a crucial role in the design of bridges and walkways, offering a safe surface for pedestrians and vehicles alike.

- Wastewater Treatment Plants The grating’s resistance to corrosion and ease of cleaning make it ideal for use in facilities that require durability and hygiene.

- Marine Applications In coastal and harbor settings, where metal equipment is frequently exposed to saltwater, serrated galvanized grating proves to be a reliable choice due to its anti-corrosive properties.

Conclusion

In today’s fast-paced industrial landscape, the importance of utilizing reliable and efficient materials cannot be overstated. Serrated galvanized grating stands out as an exceptional choice that combines safety, durability, and versatility. Its unique design ensures that workplaces comply with safety regulations while maintaining functionality across various applications. As infrastructure continues to evolve, embracing advanced materials like serrated galvanized grating will undoubtedly play a crucial role in fostering safer and more efficient industrial environments. Investing in such quality materials is not just a choice but a necessity for anyone involved in construction, manufacturing, or maintenance.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025