- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

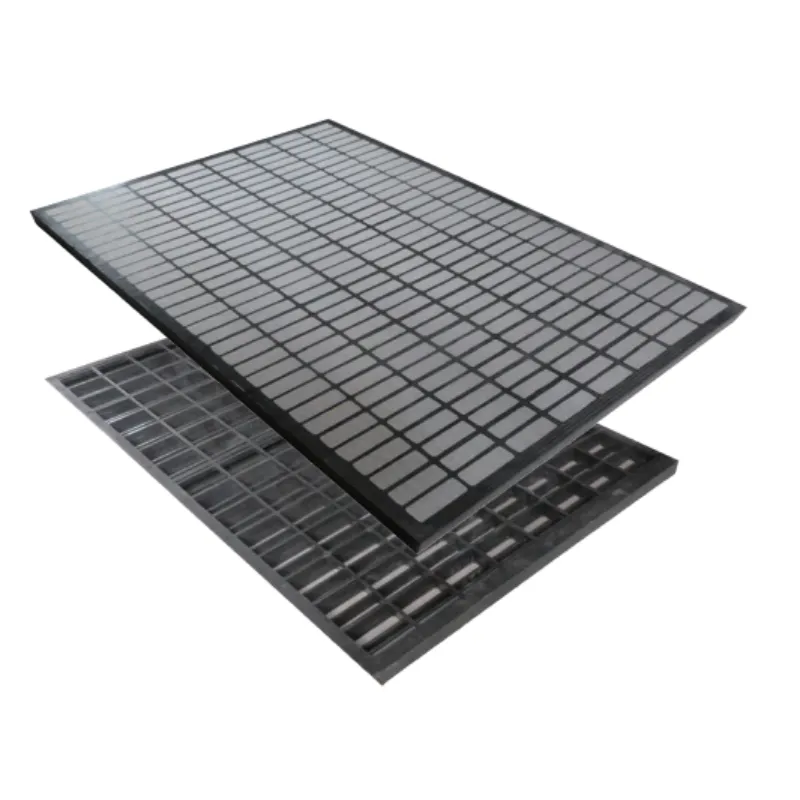

serrated flat bar

The Serrated Flat Bar A Versatile Tool in Modern Industry

In the realm of industrial materials, the serrated flat bar stands out as a significant innovation that provides a combination of strength, flexibility, and functional design. This versatile tool has become increasingly popular across various applications, thanks to its unique properties that meet the demands of modern engineering and manufacturing. To fully appreciate the serrated flat bar, it's essential to understand its design, applications, and advantages.

Design and Structure

A serrated flat bar is essentially a flat piece of metal, typically made from steel or aluminum, with a series of grooves or notches machined along one side. These serrations serve multiple purposes, primarily enhancing grip and reducing slippage when used in conjunction with other components. The thickness, width, and length of these bars can vary greatly, allowing for tailored solutions specific to different applications.

The serrated profile, reminiscent of a saw blade's teeth, ensures that the bar can interlock with other surfaces effectively. This design can significantly increase friction when two surfaces come into contact, making the serrated flat bar ideal for applications where a secure grip is vital. The inherent strength of the materials typically used allows these bars to handle significant loads, making them suitable for heavy-duty applications.

Applications Across Industries

One of the most common applications of serrated flat bars is in the construction industry. They are often used as support beams or tracks for machinery, where their serrated edges help maintain stability and prevent movement. In addition, they play a critical role in the fabrication of platforms, staircases, and walkways, providing a secure surface that minimizes the risk of slipping, particularly in outdoor or industrial environments.

Moreover, in the automotive and aerospace industries, serrated flat bars are crucial components. They are used in various assemblies where high strength and low weight are essential. The serrated edges allow for a firmer connection when bolts or other fastening methods are applied, ensuring structural integrity while maintaining the overall lightweight characteristics of the assembly.

serrated flat bar

In the manufacturing sector, these flat bars are often utilized in conveyor systems. The serrated design helps in securely holding products in place as they are transported throughout the production line, reducing the likelihood of damage and increasing efficiency.

Advantages of Serrated Flat Bars

The benefits of using serrated flat bars are numerous. One of the key advantages is their enhanced grip. In environments where safety is paramount, the ability of a serrated bar to maintain a strong connection can prevent accidents and material failure. This feature is particularly significant in high-traffic areas, such as factories or construction sites.

Another advantage is their durability. Serrated flat bars are designed to withstand harsh conditions, including exposure to chemicals, extreme temperatures, and heavy loads. This resilience not only ensures longevity but also reduces maintenance costs, making them a cost-effective solution for many applications.

Flexibility is yet another reason for the increasing popularity of serrated flat bars. They can be easily customized to meet specific requirements, whether by altering dimensions, selecting different materials, or modifying the serration pattern. This adaptability allows engineers and designers to create solutions tailored to unique challenges, promoting innovation across many fields.

Conclusion

The serrated flat bar exemplifies the synergy between design and functionality in modern industrial applications. Its unique properties allow it to serve diverse purposes, making it indispensable across many sectors, from construction and automotive to manufacturing. As industries continue to evolve and demand higher standards of safety, efficiency, and durability, the serrated flat bar stands ready to meet these challenges. By leveraging its advantages, businesses can enhance their operations, ensuring that they remain competitive in a rapidly changing market. With ongoing advancements in materials and manufacturing techniques, there is no doubt that the serrated flat bar will continue to play a crucial role in shaping the future of industrial design and application.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025