- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Serrated Flat Bar Applications and Advantages in Construction and Manufacturing Industries

Understanding Serrated Flat Bars The Perfect Blend of Functionality and Design

The construction and manufacturing industries continually seek innovative materials that improve the performance and safety of structures. Among these innovations, serrated flat bars have emerged as a noteworthy option, combining practicality with unique design features. Understanding serrated flat bars, their applications, advantages, and manufacturing process can shed light on why they are becoming increasingly popular in various sectors.

What is a Serrated Flat Bar?

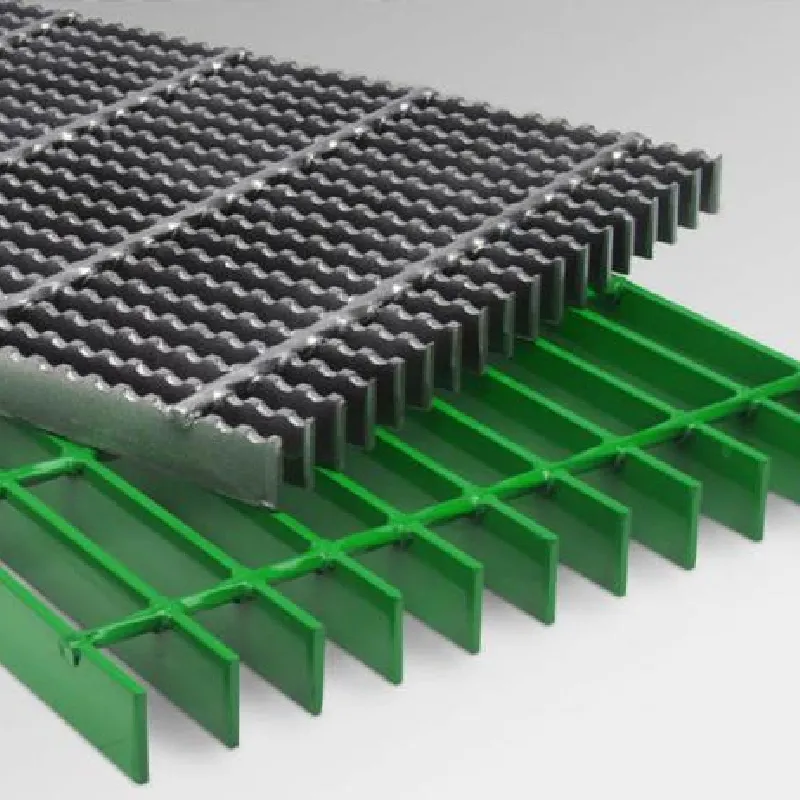

A serrated flat bar is a type of flat bar that features a serrated or notched surface along one side. This unique design provides enhanced grip, making the bars ideal for use in environments where slip resistance is crucial. Serrated flat bars are typically made from metal, such as steel or aluminum, and come in various sizes and thicknesses. Their versatility allows them to be used in numerous applications, from industrial to architectural.

Applications of Serrated Flat Bars

Serrated flat bars find applications in a multitude of settings. One of the most prominent uses is in flooring systems, particularly where pedestrian traffic occurs. The added grip of the serrated surface significantly reduces the risk of slipping, making them an ideal choice for walkways, stairs, and platforms in manufacturing facilities, warehouses, and outdoor environments.

Another significant application is in the construction of safety and support railings. Serrated flat bars can be used to create railings that are not only functional but also architecturally appealing. The serrated surface can provide additional grip for individuals who may need to steady themselves while walking or standing near such railings.

Serrated flat bars are also integral components of industrial equipment and machinery, where their anti-slip properties enhance operational safety. They are commonly used in conveyor systems, ladders, and scaffolding, where maintaining traction is essential.

Advantages of Serrated Flat Bars

serrated flat bar

One of the most significant benefits of serrated flat bars is their enhanced safety features. The serrated design provides excellent traction, reducing the likelihood of slips and falls in high-traffic areas. This feature is particularly beneficial in environments where spills or wet conditions may pose significant risks.

Durability is another crucial advantage of serrated flat bars. Constructed from sturdy materials like steel or aluminum, they are designed to withstand heavy loads and resist wear and tear over time. This durability makes them a cost-effective option, as they do not require frequent replacements.

In addition to safety and durability, serrated flat bars are also praised for their aesthetic versatility. Available in various finishes and styles, they can seamlessly integrate into a wide range of architectural designs. Whether used in industrial settings or more sophisticated architectural projects, serrated flat bars can enhance the visual appeal of any structure.

The Manufacturing Process

The production of serrated flat bars involves several steps, beginning with the selection of high-quality raw materials. Once the material is chosen, it undergoes processes such as cutting, shaping, and the creation of serrated patterns. The serration can be achieved through various methods, including milling or grinding, ensuring precision and uniformity.

After forming the serrated pattern, bars may be subjected to treatments such as galvanization or powder coating to enhance their resistance to corrosion and environmental wear. These treatments also allow for diverse color options and finishes, further increasing their design versatility.

Finally, the bars undergo a quality inspection process to ensure they meet industry standards and safety regulations before being packaged and shipped out for use in various applications.

Conclusion

Serrated flat bars represent a perfect fusion of functionality and design. With their notable anti-slip properties, robust durability, and aesthetic versatility, they are increasingly being integrated into a variety of industries. As safety and efficiency remain paramount in construction and manufacturing, serrated flat bars will continue to grow in popularity, offering innovative solutions for everyday challenges. Understanding their applications and advantages can help industries make informed decisions in material selection, ultimately contributing to safer and more effective work environments.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025