- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

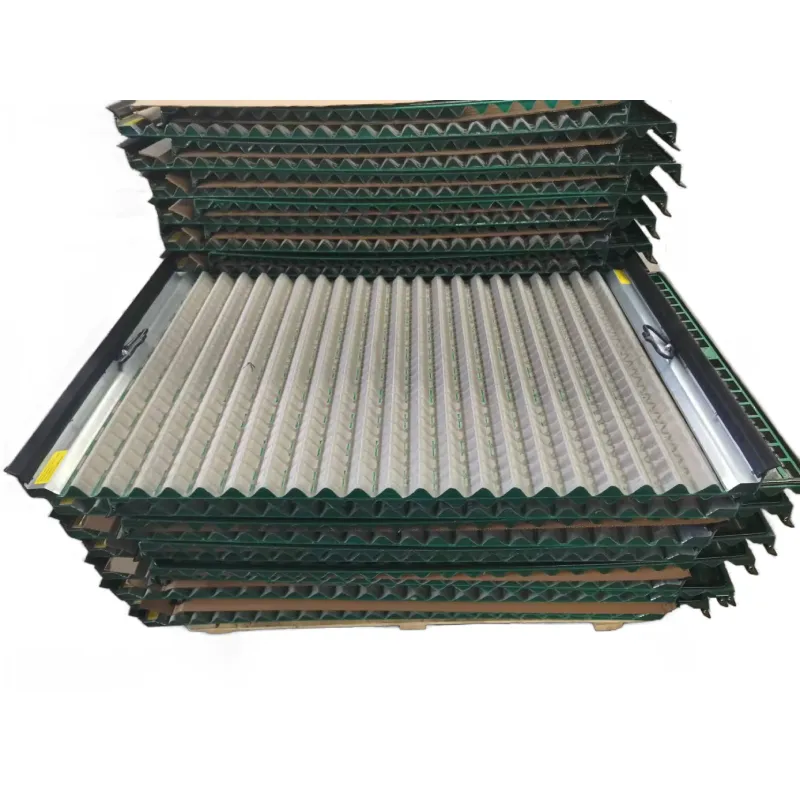

Serrated Flat Bars for Enhanced Grip and Structural Support in Various Applications

The Versatility of Serrated Flat Bars in Modern Industry

Serrated flat bars are an essential component in various industries, offering unique features and functionalities that cater to a diverse range of applications. With a specific focus on their design, manufacturing processes, and practical applications, this article aims to highlight the significant advantages and versatility of serrated flat bars in contemporary industrial settings.

What is a Serrated Flat Bar?

A serrated flat bar is characterized by its flat, elongated shape with a series of serrations or grooves along its length. These serrations are designed to enhance grip, reduce slip, and improve overall traction when the bars are used as structural or supportive elements. Typically fabricated from materials like stainless steel, carbon steel, or aluminum, serrated flat bars come in various sizes and thicknesses, making them adaptable for multiple uses.

Manufacturing Process

The production of serrated flat bars typically involves processes such as hot rolling, cold rolling, or plasma cutting, depending on the desired specifications. During hot rolling, for instance, the raw material is heated and then passed through rollers to achieve the flat bar shape. The serrations are often created through a subsequent milling or stamping process, where the patterns are pressed into the material to ensure precision and uniformity. This meticulous manufacturing ensures that the final product is durable, resistant to wear and tear, and capable of withstanding various loads and stresses.

Applications in Industries

Serrated flat bars find applications across numerous industries due to their strength, resilience, and functional design

. Here are a few notable examples1. Construction and Architecture In the construction sector, serrated flat bars are often used as stair treads and platforms. Their serrated surface provides excellent slip resistance, improving safety for workers and visitors alike. Additionally, they are used as supports for railings and guardrails, enhancing structural integrity while offering aesthetic appeal.

serrated flat bar

2. Manufacturing and Machinery In manufacturing, these bars are often employed as components in conveyor systems and material handling equipment. The serrations assist in securely holding materials in place during movement, minimizing the risk of slipping or shifting.

3. Automotive Industry Serrated flat bars are utilized in the automotive sector for various applications, including frame components and supports. The enhanced grip provided by the serrated design is crucial for ensuring stability, which is particularly important in automotive assembly processes.

4. Power Generation In power generation plants, serrated flat bars are used in various applications, such as platforms and walkways, where personnel need secure footing. Their resistance to corrosion, especially when made from stainless steel, is essential in environments exposed to moisture and harsh chemicals.

5. Marine Applications The marine industry also benefits from serrated flat bars, utilizing them in shipbuilding and offshore platforms. The serrations contribute to safety in wet conditions, where slips can be a significant hazard.

Advantages of Serrated Flat Bars

The benefits of using serrated flat bars extend beyond their physical properties. Their design allows for easy customization to meet specific requirements, and they can be easily machined or cut to fit particular dimensions. Additionally, the serrated surface can often be modified for various applications, making them highly versatile.

Moreover, serrated flat bars are cost-effective options compared to other types of safety equipment, providing a balance of performance and value. Their durability ensures a long service life, reducing replacement costs and maintenance efforts over time.

Conclusion

In summary, serrated flat bars are a crucial element in modern industry, serving a wide array of purposes across various sectors. Their unique design, combined with the versatility of materials used in their manufacture, allows them to meet the demands of both functionality and safety. As industries continue to evolve, the relevance of serrated flat bars is likely to increase, cementing their place as indispensable tools in the landscape of contemporary manufacturing and construction. Whether in enhancing safety, improving efficiency, or offering robust support, these bars will undoubtedly remain a key component in future innovations.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025