- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

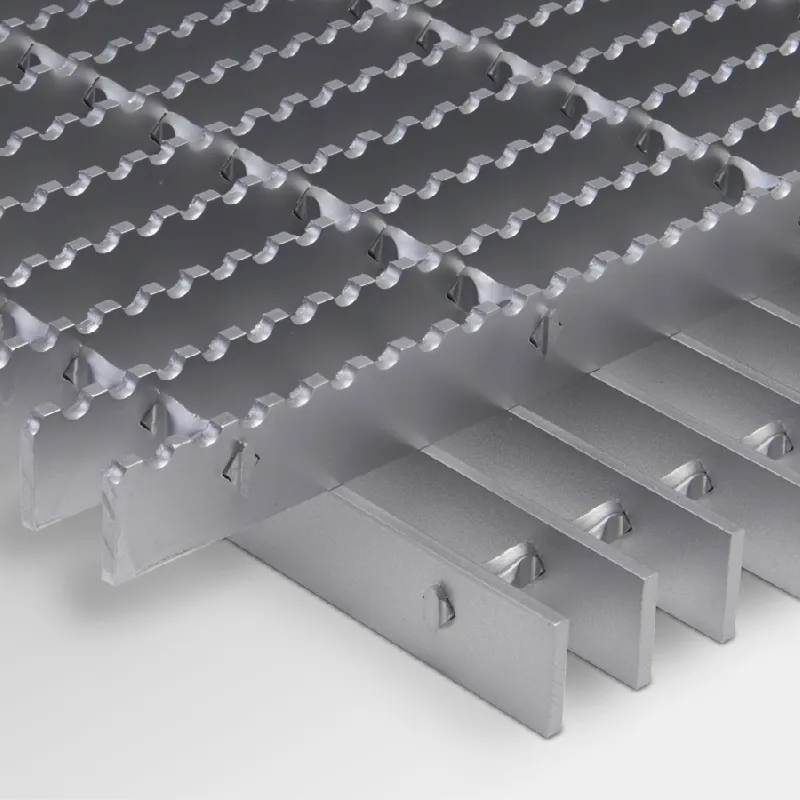

Serrated Bar Grate Design for Enhanced Filtration and Efficient Liquid Flow Management

Understanding Serrated Bar Grate A Comprehensive Overview

The serrated bar grate has gained significant attention in various industrial applications, primarily due to its unique design and functionality. This specialized type of grate, characterized by its serrated edges, offers numerous advantages that make it an essential component in many sectors, including wastewater treatment, food processing, and heavy machinery operations.

What is a Serrated Bar Grate?

A serrated bar grate is a type of filter or screening device made up of parallel bars, typically crafted from metal or high-density plastic. The bars feature serrated or notched edges, which enhance their ability to trap particles while allowing liquids or gases to pass through. This design makes serrated bar grates particularly effective for separating unwanted materials from desired fluids or for providing structural support in various settings.

Applications of Serrated Bar Grates

The use of serrated bar grates spans across multiple industries

1. Wastewater Treatment In sewage treatment plants, these grates are employed to remove large debris from incoming wastewater. The serrations help to catch and hold onto larger particles, preventing them from damaging pumps and other equipment downstream. Effective filtration at this stage is crucial to ensuring that the subsequent treatment processes run smoothly and efficiently.

2. Food Processing The food industry often utilizes serrated bar grates for their ability to facilitate the separation of solids from liquids. For example, during juice extraction or in washing systems, these grates can help remove pulp and other solids, ensuring higher purity and quality of the final product.

3. Mining and Aggregate Industries In mining operations, serrated bar grates are used for sorting and sizing materials. Their robust nature allows them to handle heavy loads, while their serrated edges effectively separate desired materials from waste.

serrated bar grate

4. Industrial Manufacturing In manufacturing settings, these grates serve as perforated support platforms or flooring, offering drainage solutions and preventing the accumulation of waste materials. Their design ensures safety by providing traction while allowing spills to drain away, minimizing hazards.

Advantages of Serrated Bar Grates

The adoption of serrated bar grates in industrial applications comes with several benefits

- Enhanced Filtration Efficiency The serrated design increases the surface area that comes into contact with particles, improving the grate's ability to capture debris and contaminants.

- Durability and Strength Typically made from corrosion-resistant materials, serrated bar grates are built to withstand harsh operating conditions, making them suitable for both indoor and outdoor environments.

- Maintenance Ease Many serrated bar grates are designed for easy cleaning and maintenance. This is particularly important in industries where hygiene standards are paramount, such as food processing.

- Customizability Serrated bar grates can be tailored to specific needs, with variations in bar spacing, height, and material composition. This flexibility allows industries to design a solution perfectly fit for their operational requirements.

Conclusion

The serrated bar grate is a versatile and essential component in various industrial applications, bringing along improved operational efficiencies and enhanced safety. Whether in the realm of wastewater treatment, food processing, or heavy machinery, their unique design and functionality make them indispensable. As industries continue to evolve and seek more effective methods for filtration and separation, the serrated bar grate will likely remain a vital tool in meeting these demands. In summary, it’s clear that investing in high-quality serrated bar grates can lead to significant long-term advantages for any organization looking to optimize their processes.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025