- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

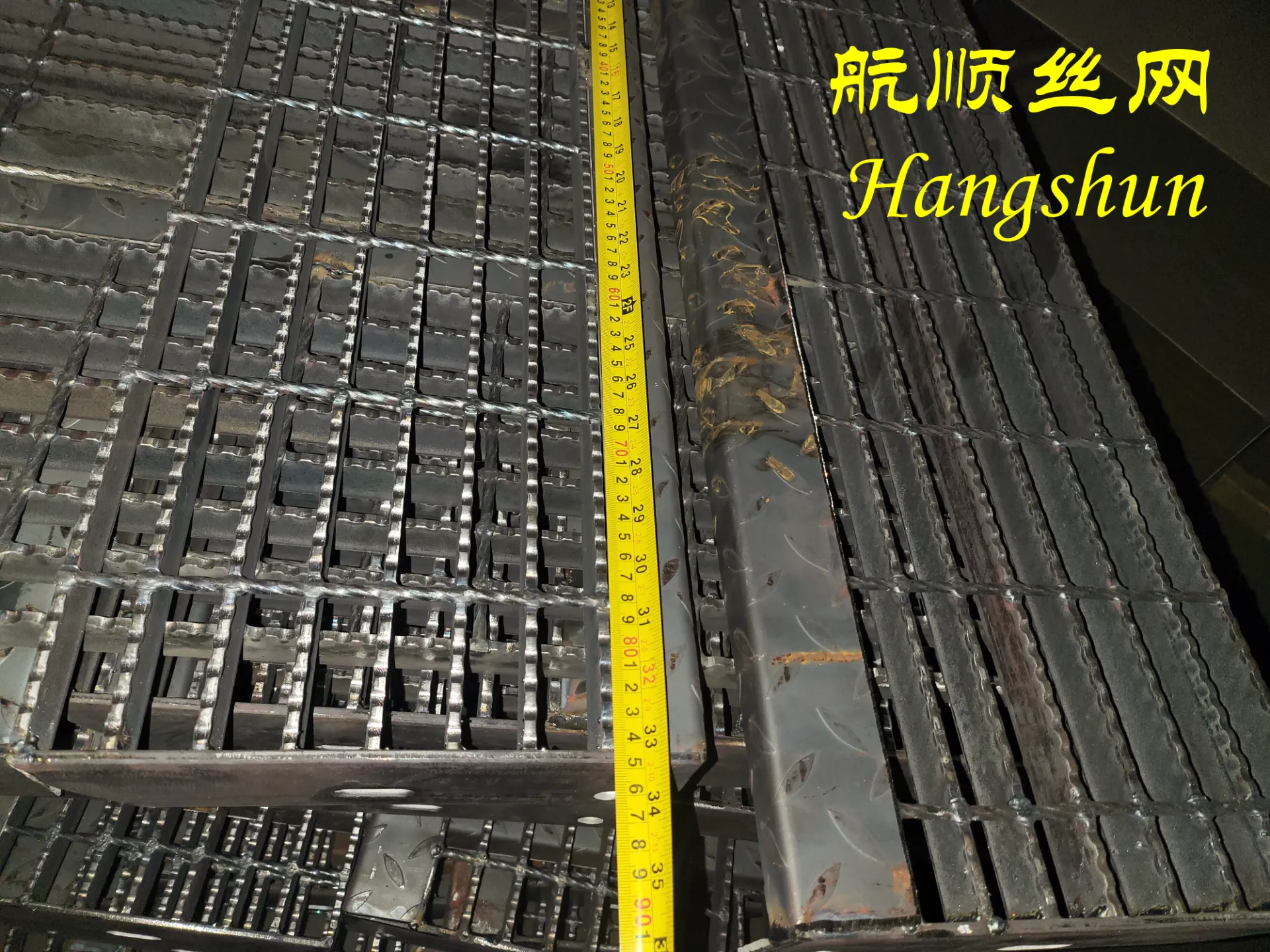

riveted grating

The Technique and Application of Riveted Grating

Riveted grating is an essential component in various construction and engineering applications, known for its strength, durability, and versatility. This technique involves fastening together metal bars or panels using rivets, resulting in a robust structure that can withstand significant loads and resist corrosion. The process and the materials used in riveted grating contribute to its effectiveness in fulfilling numerous roles across different industries.

Understanding Riveted Grating

Riveted grating is primarily made of steel, which can be hot-dip galvanized or otherwise treated to enhance its corrosion resistance. The grating consists of a series of parallel bars with cross bars welded or riveted perpendicularly, creating a stable grid-like structure. These designs can vary in spacing, thickness, and dimensions, depending on the specific application requirements.

Riveting, the process that binds the grating components, utilizes metal fasteners (rivets) to join the parts together securely. It involves creating a hole in the materials, inserting the rivet, and then deforming the tail end of the rivet to create a joint. This method is particularly advantageous in environments where welding may not be suitable due to material properties or where heat exposure could compromise the integrity of the components.

Advantages of Riveted Grating

One of the primary benefits of riveted grating is its ability to support heavy loads. This makes it an ideal choice for flooring, walkways, and platforms in industrial settings, including factories, warehouses, and processing plants. The open design of grating also allows for excellent drainage and ventilation, which is critical in environments where spills or moisture may occur.

In addition, riveted grating can be manufactured to meet specific safety standards, including slip resistance, making it a preferred choice in public spaces and high-traffic areas

. Its solid construction ensures longevity, reducing the need for frequent replacements or repairs, translating into cost savings for businesses and organizations.riveted grating

Applications of Riveted Grating

Riveted grating finds utility in a broad spectrum of applications. In industrial settings, it is commonly used for platforms, stair treads, and catwalks, where strength and safety are paramount. It can also serve as support in wastewater treatment facilities, petrochemical plants, and power generation plants, where grating must endure harsh environmental conditions.

Moreover, this grating type is increasingly utilized in architectural projects, such as bridges and public walkways. Designers appreciate riveted grating for its modern aesthetic and functionality, enhancing not only safety but also the visual appeal of structures.

Maintenance and Care

While riveted grating is known for its robustness, proper maintenance is essential to ensure its longevity. Regular inspections should be conducted to identify any signs of wear or damage. Cleaning the grating to remove debris and contaminants can prevent corrosion and preserve its integrity. In areas subject to harsh weather conditions, applying protective coatings can also extend the lifespan of the grating.

Conclusion

In conclusion, riveted grating represents an indispensable element in the realms of construction and engineering, offering a compelling mix of durability, load-bearing capacity, and aesthetic appeal. Its diverse applications across various industries underscore its significance in modern infrastructure. As technological advancements continue to evolve, riveted grating will remain a core solution for safe, reliable, and efficient construction practices.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025