- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

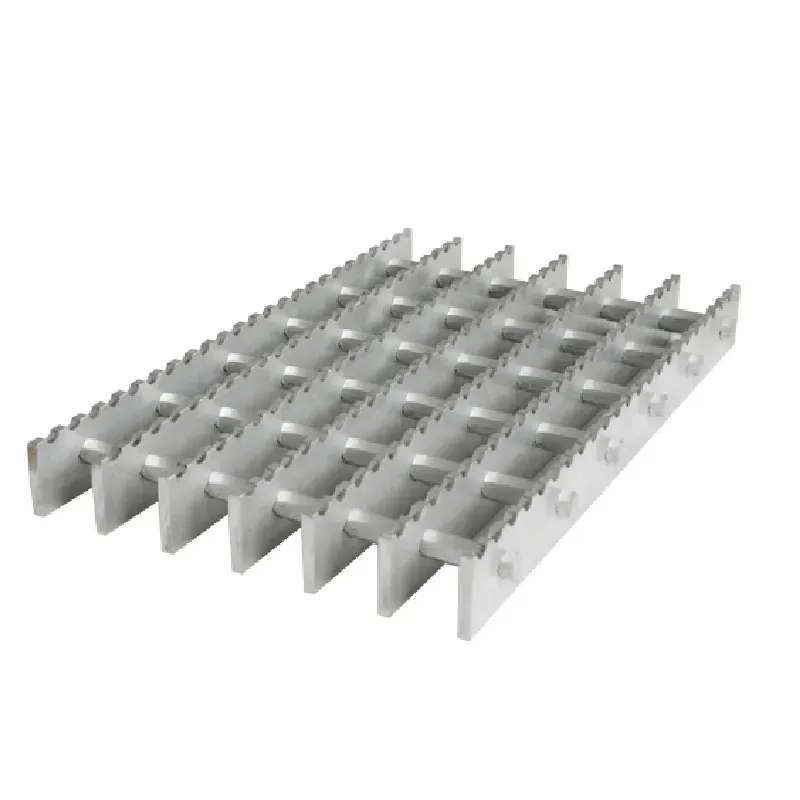

Riveted Grating: A Timeless Solution for Heavy-Duty Applications

Riveted bar grating stands as a trusted choice in industries requiring reliable, heavy-duty flooring solutions. Its construction combines load-bearing flat bars with cross bars secured by cold-pressed rivets, providing exceptional strength and stability. This unique design is highly resistant to impact and deflection, making it a preferred option for areas where durability and safety are paramount. Whether in industrial plants or high-traffic zones, riveted bar grating offers a timeless solution that guarantees superior performance under extreme conditions.

The Advantages of Open Steel Grating in Industrial Environments

Open steel grating is an essential component in facilities demanding efficient drainage and ventilation. Its design allows liquids, debris, and air to pass through effortlessly, making it ideal for applications such as wastewater treatment plants and chemical facilities. The open structure also ensures lightweight yet sturdy flooring, reducing overall structural load without compromising strength. When combined with steel grating galvanis, the grating achieves enhanced corrosion resistance, allowing it to perform reliably even in harsh environments. This combination is especially useful in offshore platforms and marine applications, where exposure to moisture and salt is a constant challenge.

The Importance of Steel Grating Panels in Structural Design

Steel grating panels serve as versatile building blocks in a wide array of industrial and commercial projects. They are pre-fabricated in standard sizes for quick installation, reducing construction time and labor costs. The panels’ rigidity and uniformity make them suitable for flooring, stair treads, and decking in industries like power generation and petrochemical processing. Furthermore, when manufactured with steel grating galvanis, these panels offer long-lasting protection against rust and wear. For projects demanding higher load-bearing capacities, steel grating heavy duty options ensure reliable performance under extreme stress, providing safety and longevity in even the most demanding applications.

Heavy-Duty Steel Grating: Built for Extreme Conditions

Steel grating heavy duty products are specifically engineered for demanding environments, such as warehouses, loading docks, and transportation hubs. Their robust construction ensures they can withstand the weight of heavy machinery, vehicles, and dynamic loads. This type of grating is often fabricated from high-strength materials like carbon steel, offering superior durability and resistance to deformation. The integration of open steel grating design within heavy-duty applications ensures excellent traction and drainage, reducing hazards and maintenance costs. Additionally, incorporating steel grating panels into the design streamlines installation, providing cost-effective solutions for large-scale projects.

Enhancing Longevity with Steel Grating Galvanis

One of the most effective ways to extend the lifespan of riveted bar grating is through galvanization. Steel grating galvanis involves coating the grating with a protective layer of zinc, which prevents rust and corrosion in exposed environments. This treatment is crucial for installations in outdoor or high-humidity areas, such as industrial walkways, parking structures, and offshore platforms. Galvanized grating not only resists wear but also maintains its aesthetic appeal, making it a popular choice for architects and engineers. Moreover, when combined with the structural advantages of steel grating heavy duty, galvanized grating delivers unparalleled performance, even in the most corrosive conditions.

Why Riveted Bar Grating is a Cost-Effective Solution

Choosing riveted bar grating for industrial applications often results in significant cost savings over time. Its robust design minimizes maintenance expenses and reduces the likelihood of replacements, even in harsh environments. Additionally, steel grating panels can be manufactured in customizable sizes and finishes to suit specific project needs, ensuring efficient material usage and reduced waste. The integration of steel grating galvanis extends the lifespan of the grating, adding long-term value to the investment. These combined advantages make open steel grating and its heavy-duty variations an economical choice for large-scale industrial operations.

Riveted bar grating remains a cornerstone in industrial applications, offering unparalleled strength, stability, and versatility. The integration of open steel grating ensures excellent drainage and ventilation, while steel grating panels simplify construction processes. For heavy-duty demands, steel grating heavy duty provides the durability needed to withstand extreme loads and challenging environments. Galvanization further enhances performance by protecting against corrosion, ensuring a long service life. By leveraging these advanced features, riveted bar grating continues to provide a timeless solution that meets the rigorous demands of modern industries.

-

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025