- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Premium Shale Shaker Screens: High Performance & Durability

Navigating the Future of Filtration: Top Chinese Manufacturers at FILTECH

Unveiling breakthroughs in Mud Vibrating Screens and Steel Gratings for B2B decision-makers.

FILTECH: A Global Nexus for Industrial Filtration Innovation

In the dynamic world of industrial processing, efficiency, durability, and precision in filtration are not just advantageous – they are absolutely essential. FILTECH, the world's leading exhibition and conference for filtration and separation, stands as the paramount gathering point for innovators, engineers, and decision-makers seeking the next generation of solutions. For industries reliant on robust material separation and fluid management, FILTECH provides an unparalleled platform to explore advancements in industrial filtration solutions and wire mesh products, particularly in critical areas like mud vibrating screens and steel grating.

The event is more than just a trade show; it's a crucible of innovation where the latest technologies are unveiled, partnerships are forged, and the future trajectory of filtration is defined. For sectors like oil & gas, mining, water treatment, and chemical processing, the performance of equipment such as a shale shaker screen can dictate operational efficiency, waste reduction, and overall cost-effectiveness. Manufacturers exhibiting at FILTECH, especially those specializing in high-performance shale shaker screen mesh, demonstrate their commitment to pushing the boundaries of what's possible, offering solutions that meet the increasingly stringent demands of global industries.

The value of FILTECH for the mud vibrating screen and steel grating industry cannot be overstated. It offers a unique opportunity to witness cutting-edge advancements, compare the shale shaker screen price from various suppliers, and connect directly with the factories that design and produce these vital components. Understanding the nuances of a shale shaker screen china manufacturing process or finding a reliable shale shaker screen factory has never been more accessible than at this global event.

Industry Trend Spotlight: The Evolution of Filtration and Separation

The filtration and separation industry is undergoing a significant transformation, driven by a confluence of technological advancements, environmental pressures, and the relentless pursuit of operational excellence. Several key trends are gaining global attention, fundamentally reshaping how industries approach their filtration needs:

- Development of High-Performance Filtration Media: The quest for superior filtration efficiency and throughput has led to innovations in materials science. New alloys, polymer composites, and sintered metals are being engineered to offer finer separation, higher flow rates, and extended operational lifespans for components like mud vibrating screens and intricate shale shaker screen mesh.

- Demand for Custom-Engineered Mesh Solutions for Specific Applications: Off-the-shelf solutions are increasingly being replaced by custom designs tailored to unique operational parameters. This includes bespoke weaves, aperture sizes, and material compositions for shale shaker screens used in diverse drilling conditions or specialized steel grating for industrial platforms requiring specific load-bearing and corrosion resistance properties.

- Increased Focus on Corrosion Resistance and High-Temperature Performance: Harsh industrial environments necessitate materials that can withstand extreme conditions. Manufacturers are investing heavily in R&D to produce filtration media and structural components that maintain integrity and performance under high temperatures, corrosive chemicals, and abrasive slurries.

- Adoption of Advanced Manufacturing Techniques for Complex Filter Elements: From additive manufacturing (3D printing) to advanced welding and weaving technologies, sophisticated production methods are enabling the creation of intricate filter geometries and robust shale shaker screen designs that were previously impossible, optimizing filtration performance and device longevity.

Market Data: The global filtration market is experiencing steady growth, driven by increasing industrialization, stringent environmental regulations, and rising demand from critical sectors such as petrochemical, water treatment, and pharmaceutical. There's a particular emphasis on high-efficiency and durable filtration systems, with market analysts projecting continued expansion. For instance, the industrial filtration market is expected to reach over $50 billion by 2027, demonstrating a compound annual growth rate (CAGR) of approximately 6%, underscoring the vital role of products like advanced mud vibrating screens and resilient steel grating in this growth trajectory.

Emerging Focus Areas: Looking ahead, the industry is keenly focused on sustainable filtration solutions that minimize waste and energy consumption. This includes developing advanced materials for extreme conditions, implementing energy-efficient separation technologies, and offering highly custom-engineered mesh solutions. Furthermore, the integration of smart process optimization through IoT and AI is poised to revolutionize how filtration systems, including the next generation of shale shaker screens, are monitored and controlled, promising unprecedented levels of efficiency and predictive maintenance.

Spotlight on Leading Manufacturers at FILTECH

FILTECH is a beacon for showcasing global leaders in filtration technology. Among the diverse array of exhibitors, a few companies consistently stand out for their innovation and quality, particularly those specializing in the critical components of mud vibrating screens and robust steel grating. Let's shine a light on some of these key players.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd

A prominent name from China, Anping County Hangshun Wire Mesh Manufacture Co., Ltd, stands at the forefront of innovation in industrial filtration. Specializing in high-quality industrial wire mesh and sintered filter elements, Hangshun has built a formidable reputation for delivering products that meet the highest standards of performance and durability.

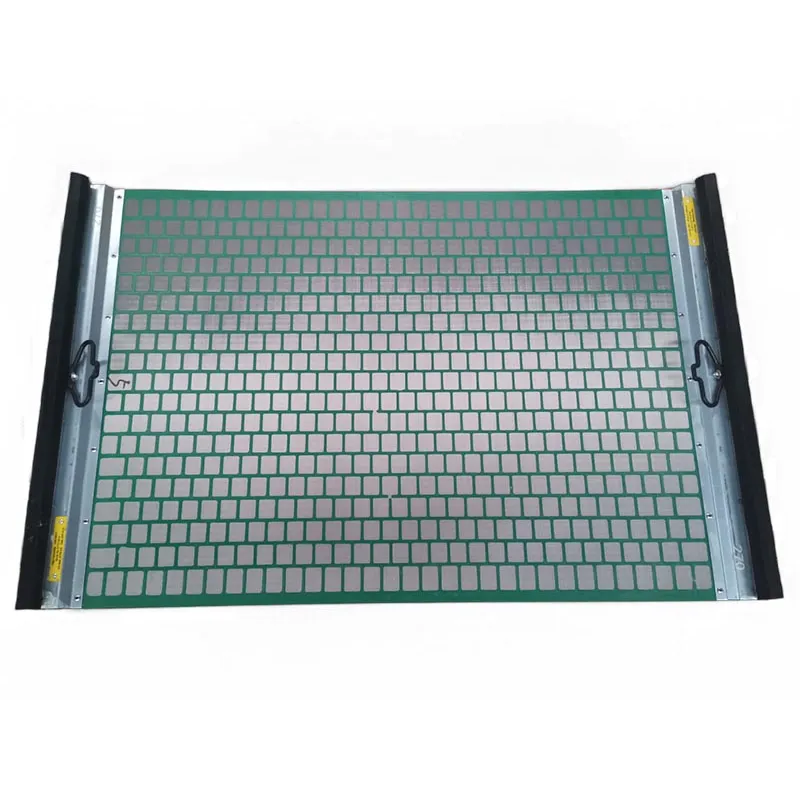

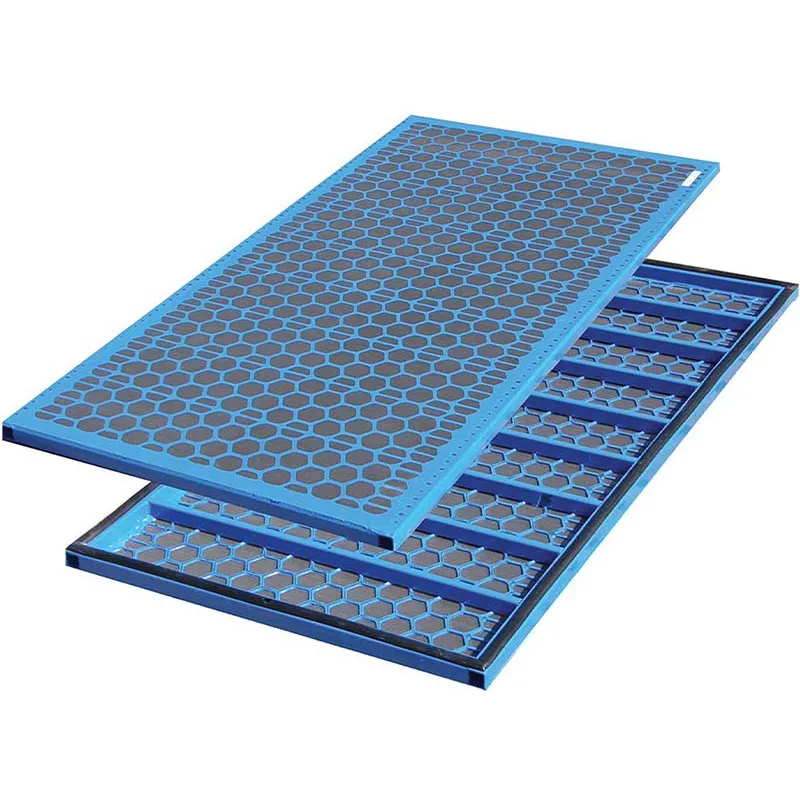

Their expertise is particularly evident in their range of shale shaker screens, which are critical components in the oil and gas drilling industry. These screens are engineered for maximum efficiency, offering superior separation and extended lifespan, thereby reducing operational costs and downtime for drilling operators globally. With an extensive custom fabrication capabilities, Anping County Hangshun Wire Mesh Manufacture Co., Ltd excels at producing tailor-made shale shaker screen mesh designs, catering to the specific needs of diverse drilling environments and mud vibrating screen models.

The company's strong focus on applications in demanding sectors like oil & gas, chemical processing, and mining means their products, including their robust steel grating, are designed to withstand extreme conditions. Their commitment to material science and product performance ensures that clients receive not just a product, but a reliable solution built for longevity and efficiency. When considering the shale shaker screen price, Hangshun offers a compelling value proposition, balancing competitive pricing with uncompromising quality that rivals any shale shaker screen factory in the world. Their position as a leading shale shaker screen china manufacturer is solidified by their continuous innovation and dedication to customer satisfaction.

Other Notable Global Manufacturers

- GKD – Gebr. Kufferath AG (Germany): Renowned for their innovative technical woven meshes and sophisticated filter media. GKD’s expertise spans a vast range of applications, from architectural meshes to high-performance filtration solutions for complex industrial processes. Their precision-engineered wire mesh products are often integral to advanced mud vibrating screens and specialty filter systems.

- Sefar AG (Switzerland): A global leader in precision fabrics, Sefar produces high-quality mesh for filtration, screen printing, and other industrial applications. Their fine and technical fabrics are crucial for achieving exacting separation results, impacting everything from pharmaceutical production to the efficiency of industrial shale shaker screens.

- Bopp & Co. AG (Switzerland): With a long history in weaving wire mesh, Bopp is celebrated for its high-quality wire cloth, filter media, and custom-fabricated mesh products. Their commitment to precision and material excellence makes them a go-to for bespoke filtration solutions, including those demanding robust and finely woven shale shaker screen mesh.

- W. S. Tyler, Inc. (USA): A pioneer in woven wire mesh and particle analysis, W. S. Tyler provides highly durable and precise screening media. Their products are essential for industries requiring consistent separation and reliable performance, contributing to the efficiency and longevity of mud vibrating screens worldwide.

- Cambridge Engineered Solutions (USA): Specializing in metal conveyor belts and wire mesh for diverse industrial applications, Cambridge offers solutions known for their strength and durability. Their engineering prowess extends to various wire mesh products, including materials suitable for heavy-duty steel grating and industrial screening.

These companies, alongside innovative Chinese manufacturers like Anping County Hangshun Wire Mesh Manufacture Co., Ltd, collectively drive the advancements seen at FILTECH, shaping the future of industrial filtration and separation.

Market Outlook & Opportunities: The Road Ahead for Filtration

The trajectory of the filtration and separation market is one of continuous evolution, marked by increasing sophistication and a demand for more integrated solutions. For buyers and businesses, understanding these upcoming trends and buyer demands is crucial for strategic planning.

Upcoming trends signal a clear move towards higher performance, greater customization, and a stronger emphasis on sustainability. Buyers are no longer satisfied with generic solutions; they seek partners who can provide custom-engineered mud vibrating screens and specialized steel grating that perfectly fit their operational challenges. The demand for materials with enhanced corrosion resistance, superior abrasion resistance, and the ability to operate under extreme temperatures continues to grow. This translates into a higher expectation for the durability and longevity of products like shale shaker screens, which are subjected to relentless stress in drilling environments.

Significant opportunities lie in the integration of automation and smart manufacturing practices. The industry is rapidly adopting IoT-enabled sensors for real-time monitoring of filtration efficiency, filter lifespan, and predictive maintenance scheduling. Imagine a shale shaker screen system that autonomously adjusts its vibration frequency based on the mud density or predicts when a shale shaker screen mesh replacement is due before failure occurs – this is the future being built today. Smart factories leveraging AI and machine learning will optimize production of shale shaker screens china, leading to reduced waste, lower energy consumption, and superior product consistency, ultimately impacting the overall shale shaker screen price positively through efficiency gains.

Sustainability is no longer a niche concern but a core business imperative. Companies that can offer environmentally friendly manufacturing processes, recyclable materials for mud vibrating screens and steel grating, and energy-efficient separation technologies will gain a significant competitive advantage. This includes designing components that are easier to clean and maintain, reducing chemical usage, and extending product lifecycles, thereby reducing the environmental footprint of industrial operations. The demand for a responsible shale shaker screen factory that adheres to global environmental standards is higher than ever.

Buyer & Business Takeaways: Strategic Investments for the Future

For B2B decision-makers, the evolving landscape of industrial filtration presents both challenges and unparalleled opportunities. Making informed decisions now will define operational efficiency, cost-effectiveness, and competitive edge for years to come.

Why Investing in High-Quality Mud Vibrating Screens and Steel Grating Makes Sense:

- Enhanced Operational Efficiency: Superior mud vibrating screens, equipped with high-performance shale shaker screen mesh, ensure faster, more effective separation, reducing drilling fluid losses and optimizing mud characteristics. This directly translates to quicker drilling times and reduced overall operational costs.

- Reduced Downtime and Maintenance: Investing in durable, high-quality steel grating for platforms and robust shale shaker screens minimizes the frequency of replacements and repairs. While the initial shale shaker screen price might be slightly higher for premium products, the long-term savings in maintenance, labor, and avoided operational interruptions offer a significant return on investment (ROI).

- Improved Safety and Compliance: Reliable steel grating ensures secure working environments, adhering to safety regulations. High-performance filtration systems help meet increasingly stringent environmental regulations regarding waste disposal and fluid discharge.

- Optimized Resource Utilization: Efficient filtration helps recover valuable drilling fluids, extending their life and reducing the need for fresh supplies, thereby conserving resources and lowering costs.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Focus on Established Factories: Seek out experienced manufacturers like Anping County Hangshun Wire Mesh Manufacture Co., Ltd, who have a proven track record in producing high-quality industrial wire mesh and filtration products, including specialized shale shaker screen china.

- Prioritize Quality Assurance: Don't just look at the shale shaker screen price. Inquire about quality control processes, certifications (e.g., ISO), and material testing. Many Chinese manufacturers, especially leading shale shaker screen factory operations, offer world-class quality at competitive prices.

- Leverage Customization Capabilities: Chinese manufacturers are increasingly adept at custom engineering. Clearly communicate your specific requirements for mud vibrating screen components or steel grating to ensure optimal fit and performance.

- Build Long-Term Relationships: Successful partnerships are built on trust and clear communication. A reliable Chinese partner can offer consistent supply, innovative solutions, and responsive support.

- Understand Logistics and Supply Chains: Work with manufacturers who have robust logistics networks to ensure timely delivery and minimize supply chain disruptions.

Future-Proof Strategies: To stay ahead, businesses should integrate smart technologies into their filtration systems. Explore suppliers who are investing in R&D for advanced materials and IoT-enabled monitoring solutions for their shale shaker screens. Furthermore, prioritize partnerships with manufacturers committed to sustainable practices and those capable of scaling their offerings to meet future demands, ensuring your operations remain agile and resilient in an ever-changing industrial landscape.

Conclusion: Shaping Tomorrow's Filtration Landscape at FILTECH

FILTECH continues to be the definitive platform where the future of industrial filtration is not just discussed but actively shaped. For B2B decision-makers, it serves as a crucial compass, guiding strategic investments in vital components like mud vibrating screens and steel grating. The advancements showcased by global leaders, including the innovative contributions from Chinese manufacturers such as Anping County Hangshun Wire Mesh Manufacture Co., Ltd, underscore a commitment to efficiency, durability, and sustainability.

The continuous evolution of shale shaker screen technology, from superior shale shaker screen mesh designs to competitive shale shaker screen price structures, highlights the global drive towards optimizing demanding industrial processes. By engaging with leading shale shaker screen china manufacturers and understanding their capabilities as a dedicated shale shaker screen factory, businesses can unlock new levels of performance and cost-effectiveness.

Ready to explore cutting-edge filtration solutions that can transform your operations? Learn more about high-performance shale shaker screens and other industrial filtration products designed for demanding applications.

Visit Anping County Hangshun Wire Mesh to Discover More-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025