- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

plastic frame shaker screen

The Evolving World of Plastic Frame Shaker Screens

In the realm of industrial processes, shaker screens play a pivotal role, particularly in the oil and gas, mining, and construction industries. Among the various types of shaker screens available, plastic frame shaker screens have garnered significant attention for their unique advantages and applications. This article delves into the characteristics, benefits, and future prospects of plastic frame shaker screens, highlighting their impact on operational efficiency and sustainability.

Understanding Shaker Screens

Shaker screens are integral components of filtration systems, utilized to separate solids from liquids. The basic function of these screens is to permit certain particles to pass through while retaining others, ensuring that the output stream meets the required specifications. Traditionally, shaker screens were constructed from metal frames with woven wire mesh, ensuring both durability and reliability. However, innovations in materials have led to the emergence of plastic frame shaker screens, which offer competitive advantages over their metal counterparts.

Advantages of Plastic Frame Shaker Screens

1. Lightweight and High Durability The primary benefit of plastic frame shaker screens lies in their lightweight nature. This characteristic makes them easier to handle, transport, and install compared to heavier metal screens. Additionally, modern plastics are engineered to possess high resistance to corrosion and wear, extending the lifespan of these screens far beyond that of traditional metal options.

2. Cost-Effectiveness The production of plastic frame shaker screens tends to be more cost-effective than metal construction. This reduction in manufacturing costs translates to lower prices for end-users, making them an attractive option for companies seeking to optimize their budget while maintaining quality.

3. Enhanced Performance Plastic frames can be designed to accommodate various mesh sizes and configurations, allowing for tailored solutions that meet the specific needs of different applications. Furthermore, the smooth surface of plastic frames minimizes particle adhesion, reducing blinding and increasing efficiency during operations.

plastic frame shaker screen

4. Environmental Considerations As industries increasingly focus on sustainability, plastic frame shaker screens provide a more environmentally friendly alternative. Many manufacturers are now producing screens from recyclable materials, reducing waste and promoting a circular economy. Moreover, the lightweight design contributes to lower transportation emissions, aligning with global sustainability goals.

5. Resistance to Chemicals In industries such as oil and gas, exposure to harsh chemicals is unavoidable. Plastic frame shaker screens are often designed to withstand a wide range of chemical interactions without degrading, thus ensuring reliability even in challenging environments.

Applications Across Industries

Plastic frame shaker screens have found their application across various sectors. In the oil and gas industry, they are utilized for drilling mud separation, while in the mining sector, they facilitate the efficient separation of valuable minerals from waste materials. The construction industry incorporates these screens in processes such as sand and gravel separation, providing precise sizing required for construction materials.

Challenges and Future Perspectives

Despite their advantages, plastic frame shaker screens are not without challenges. Their resistance to high temperatures can be a limitation in some applications, necessitating ongoing research into high-temperature-resistant materials. Nevertheless, the future of plastic frame shaker screens appears bright. Continuous advancements in polymer science may lead to the development of even more resilient materials, expanding the range of applications and improving overall performance.

Conclusion

Plastic frame shaker screens represent a significant advancement in filtration technology, combining efficiency, cost-effectiveness, and environmental consciousness. As industries worldwide continue to evolve, the adoption of innovative solutions like plastic frame shaker screens will be critical in enhancing productivity and sustainability. By embracing these modern materials, companies can not only improve their operational efficiency but also contribute positively to the environment. The journey toward a more sustainable and efficient industrial world is well underway, and plastic frame shaker screens are at the forefront of this transformation.

-

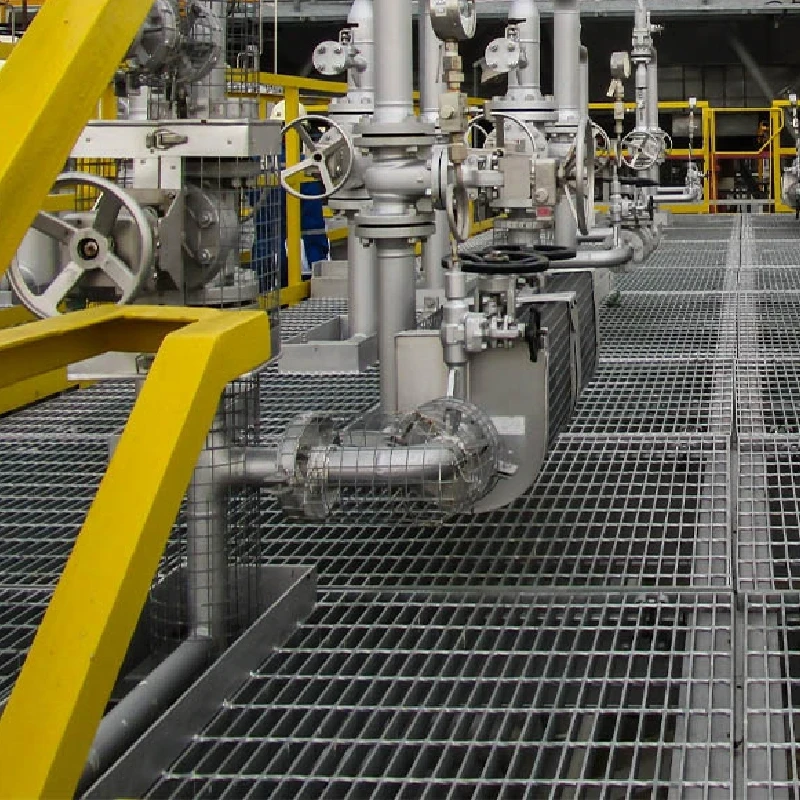

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025