- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Innovative Plastic Frame Shaker Screens for Enhanced Separation Efficiency and Durability

The Importance of Plastic Frame Shaker Screens in Modern Industries

In contemporary industrial applications, especially within the oil and gas sector and mineral extraction, the efficiency of solids control equipment plays a fundamental role in ensuring optimal productivity and environmental compliance. One of the critical components of this equipment is the shaker screen, and in recent years, plastic frame shaker screens have garnered significant attention due to their innovative design and functional advantages.

What are Shaker Screens?

Shaker screens are vital components in shale shakers, which are equipment used to separate solids from liquids, specifically in drilling operations. The purpose of these screens is to facilitate the separation process by allowing fluid to pass while retaining larger particles. Traditionally, shaker screens were made with metal frames, which, while durable, presented several challenges such as corrosion, weight issues, and higher manufacturing costs.

The Rise of Plastic Frame Shaker Screens

Plastic frame shaker screens have emerged as a modern alternative to their metal counterparts. These screens are typically constructed using high-quality, engineered plastics that offer numerous advantages. One of the primary benefits is the reduction in weight, making them easier to transport and install. This lightweight nature also contributes to reduced energy consumption in shaker operations since the equipment can operate more efficiently with less strain.

Moreover, plastic frame shaker screens exhibit exceptional resistance to corrosion and chemicals. In many drilling environments, exposure to various drilling fluids can lead to rapid deterioration of conventional metal frames. The longevity of plastic frames reduces the frequency of replacements, thereby optimizing operational costs and minimizing downtime.

Performance Enhancements

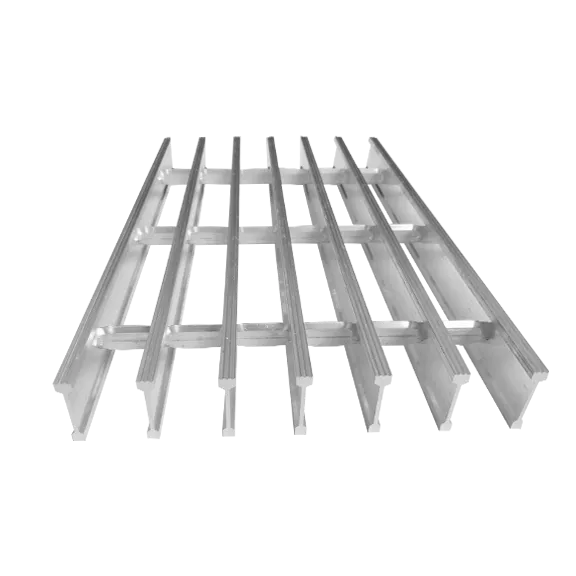

plastic frame shaker screen

The design and mesh configurations of plastic frame shaker screens can be tailored to meet specific operational needs. Customized mesh sizes allow for precise separation of solids based on various drilling conditions. Furthermore, advancements in manufacturing technology enable the production of screens that offer improved throughput and larger surface areas, significantly enhancing the efficiency of the solids separation process.

Another critical aspect is the ability to maintain optimal screen tension. Proper tensioning is crucial for effective performance, and plastic frames can often achieve better and more consistent tension than some traditional metal frames. This feature directly impacts the screening performance, as it helps prevent blinding and ensures a steady flow of fluids through the screen.

Environmental Considerations

In today’s environmentally conscious world, the choice of materials and processes in industrial applications has become increasingly important. Plastic frame shaker screens not only offer performance benefits but also contribute to sustainability efforts. The reduced need for replacements and the potential for recycling engineered plastics at the end of their lifecycle translate into less waste and a lower carbon footprint.

Conclusion

As industries continue to evolve and prioritize operational efficiency, cost-effectiveness, and environmental sustainability, the adoption of plastic frame shaker screens is likely to increase. Their numerous advantages over traditional metal frame screens make them an attractive option for operators looking to enhance their drilling and separation processes.

The integration of plastic frame shaker screens in the oil and gas sector, as well as in other industries such as mining and construction, is a testament to the ongoing innovations in materials technology that aim to meet modern challenges. With their superior durability, customizable performance, and environmental benefits, plastic frame shaker screens are indeed shaping the future of solids control in industrial applications. As we witness these advancements, it is clear that such innovations will play a crucial role in the ongoing quest for efficiency and sustainability in industrial operations worldwide.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025