- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

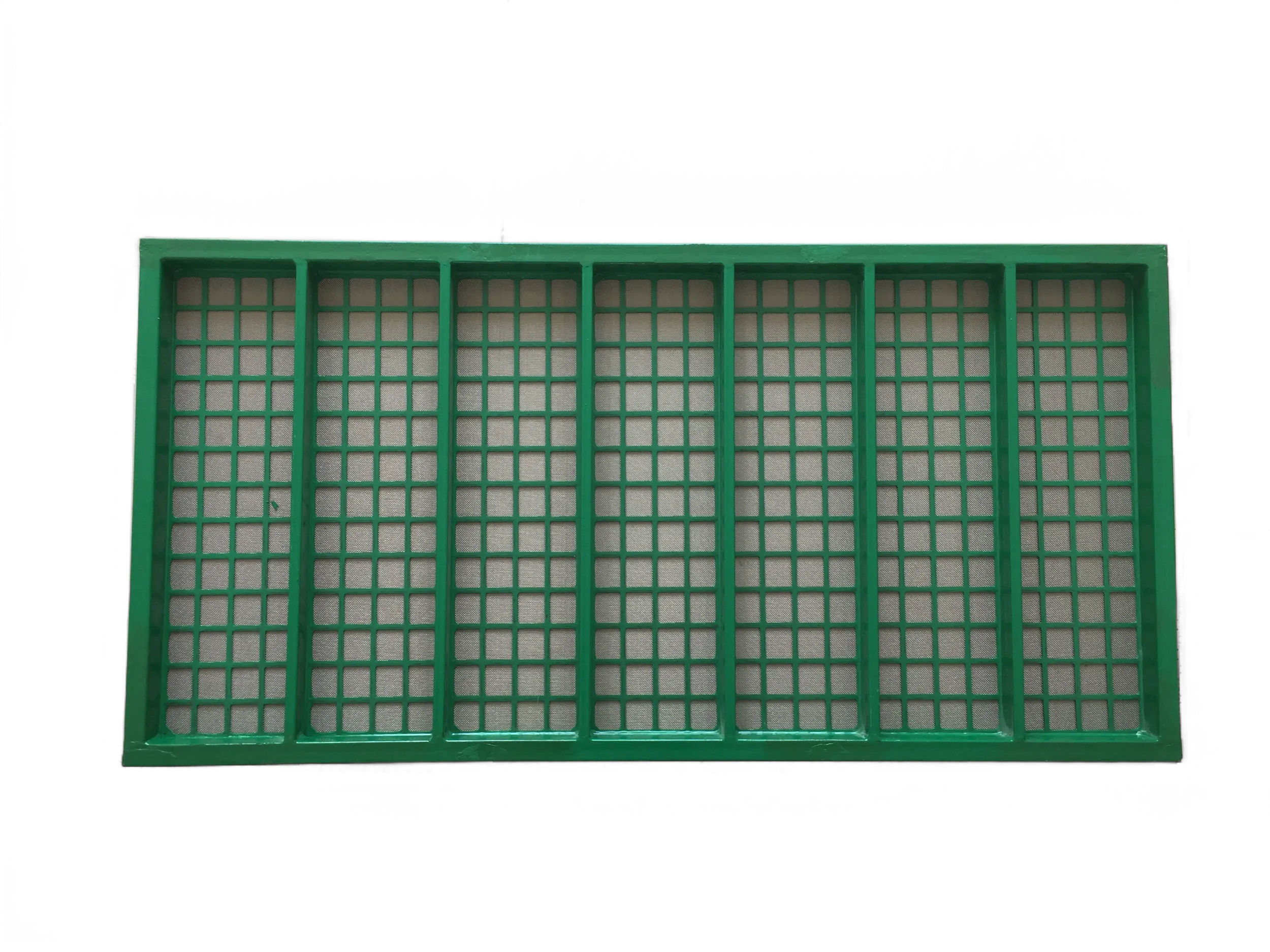

plastic frame shaker screen

The Role of Plastic Frame Shaker Screens in the Oil and Gas Industry

In the oil and gas industry, the separation of solid particles from drilling fluids is a vital task that directly affects the efficiency and costs of drilling operations. One of the essential components in the process of separating these solids is the shaker screen. Among the various types of shaker screens available, plastic frame shaker screens have emerged as a significantly beneficial option. This article explores the advantages and applications of plastic frame shaker screens in the industry.

Plastic frame shaker screens are designed to optimize the performance of shale shakers, which are essential equipment used during drilling operations. These screens are constructed with a polymer material for the frame, which provides several advantages over traditional metal frames. The lightweight nature of plastic frames allows for easier handling and installation, reducing the downtime associated with equipment changes.

One of the most compelling benefits of plastic frame shaker screens is their resistance to corrosion and chemical damage. In drilling operations, screens are often exposed to various harsh chemicals and environmental conditions. Unlike metal frames, which can corrode over time, plastic frames maintain their integrity and performance, making them a more durable choice for continuous use in the field. This durability translates to lower maintenance costs and extended service life, making them a cost-effective solution for drilling companies.

plastic frame shaker screen

Additionally, plastic frame shaker screens provide superior screening efficiency. Their design allows for better fluid and solid separation, which is crucial in ensuring that drilling fluids are adequately cleaned and reused. This efficiency not only conserves resources but also enhances the overall performance of the drilling operation. By using plastic frame screens, companies can improve the quality of their drilling fluids, allowing for more effective drilling and reduced operational costs.

Another significant advantage of plastic frame shaker screens is their flexibility in design and customization. Manufacturers can produce screens with a range of mesh sizes to meet specific drilling needs. This customization allows oil and gas companies to tailor their shaker screens to the particular requirements of their drilling environment, whether that involves dealing with sandy soils, clay-heavy environments, or other geological conditions. Furthermore, the adaptability in screen design enables easier integration with existing shaker systems.

Environmentally, plastic frame shaker screens are also a more sustainable option. The use of plastic materials that are recyclable reduces the environmental footprint associated with drilling operations. As the industry increasingly moves towards more sustainable practices, using eco-friendly materials becomes an important consideration. Companies that adopt plastic frame shaker screens not only benefit from their operational advantages but also align with broader environmental goals.

In conclusion, plastic frame shaker screens play a crucial role in enhancing the efficiency and effectiveness of the drilling process within the oil and gas industry. Their lightweight construction, resistance to corrosion, superior separation capabilities, customizable designs, and environmental advantages make them an attractive option for drilling companies striving to optimize their operations. As the demand for more efficient and sustainable drilling practices grows, the adoption of technologies such as plastic frame shaker screens is likely to become increasingly prevalent, paving the way for advancements in drilling technology and practices in the future. The benefits they offer not only enhance operational performance but also contribute to the long-term sustainability of the industry.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025