- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

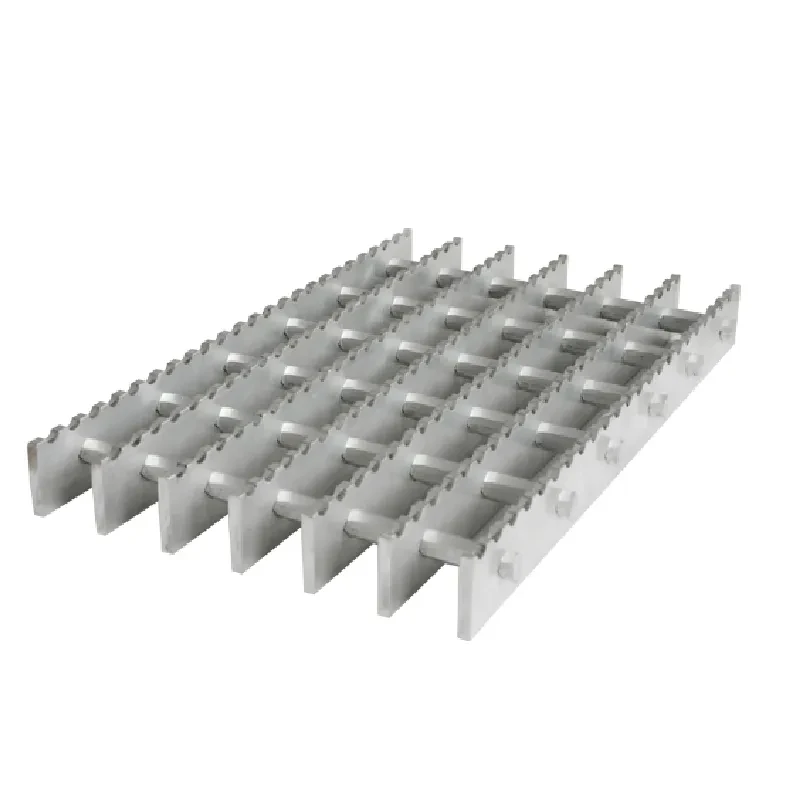

plastic frame shaker screen

The Benefits and Applications of Plastic Frame Shaker Screens in the Oil and Gas Industry

In the realm of the oil and gas industry, efficient separation of solids from fluids is crucial for maintaining operational efficacy. One of the pivotal tools utilized to achieve this is the shaker screen, specifically those constructed with plastic frames. These screens have gained popularity due to their myriad benefits and applications, which will be discussed in this article.

What Are Plastic Frame Shaker Screens?

Plastic frame shaker screens are specialized screens used in shale shakers, which are devices designed to separate drilling cuttings from the drilling fluid. Traditionally, shaker screens were made from metal, which, while durable, often presented challenges such as added weight and susceptibility to corrosion. The introduction of plastic frames has revolutionized this aspect of drilling operations. These screens are generally constructed from high-density polyethene (HDPE) or other high-performance plastics that provide significant advantages over their metal counterparts.

Advantages of Plastic Frame Shaker Screens

1. Weight Reduction One of the most significant benefits of plastic frame shaker screens is their lightweight nature. This reduction in weight translates into lower transportation costs and easier handling during installation and maintenance. Operators can manage these screens without the need for heavy machinery, leading to enhanced safety and efficiency on-site.

2. Corrosion Resistance Plastic frames are inherently resistant to corrosion, which is a considerable issue in the oil and gas industry due to the harsh chemical environments. Unlike metal frames that can degrade over time, plastic frames maintain their integrity and performance, leading to longer-lasting products and reduced replacement costs.

3. Cost-Effectiveness While the initial investment in plastic frame shaker screens may be comparable to metal options, the total cost of ownership decreases when considering their longer lifespan and reduced maintenance needs. Over time, the savings incurred from lower replacement and operational costs can be significant.

plastic frame shaker screen

4. Customizability Plastic frame screens can be tailored to specific applications and requirements. Manufacturers often offer a variety of mesh sizes and configurations that can be customized based on the particular challenges faced in different drilling environments. This flexibility ensures optimal performance in separating solids from drilling fluids.

5. Enhanced Performance The design and material properties of plastic frames allow for greater flexibility, which can lead to improved performance under different operational conditions. For instance, during high-frequency vibrations, these screens can maintain their shape and function, providing consistent separation efficiency.

Applications in the Oil and Gas Industry

Plastic frame shaker screens are utilized in various phases of drilling operations, particularly in the exploration and production stages. They are essential in

- Shale Shakers These screens are primarily used in shale shakers to remove unwanted solids, thereby maintaining the cleanliness of the drilling fluid and extending its life. This, in turn, reduces the need for frequent fluid replacements and associated costs. - Mud Recycling Systems In mud recycling systems, plastic frame shaker screens play a vital role by ensuring that solid particles are efficiently separated from the drilling mud. This recycling process is crucial for environmental sustainability and cost reduction in drilling operations.

- Horizontal Directional Drilling (HDD) The adaptability of plastic frame screens makes them suitable for HDD applications where managing the fluid's viscosity and consistency is critical in navigating through various geological formations.

Conclusion

In conclusion, plastic frame shaker screens are an innovative solution in the oil and gas industry that addresses numerous operational challenges. With their lightweight design, corrosion resistance, cost-effectiveness, customizability, and enhanced performance, these screens are poised to become a standard in effective drilling operations. As the industry continues to strive for efficiency and sustainability, the demand for such advanced tools will likely increase, solidifying the role of plastic frame shaker screens in the future of drilling technologies.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025