- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Versatile Plastic Frame Shaker Screens for Enhanced Filtration and Durability

The Advantages of Plastic Frame Shaker Screens in Modern Drilling Operations

In the world of drilling and exploration, efficiency and reliability are paramount. One of the key components that play a significant role in the drilling process is the shaker screen. Among various designs and materials, plastic frame shaker screens have emerged as a popular choice for many companies in the oil and gas industry. This article delves into the advantages of plastic frame shaker screens and why they are increasingly favored over traditional metal frame options.

Understanding Shaker Screens

Shaker screens are crucial in the drilling process as they separate the cuttings from the drilling fluid, ensuring the mud remains reusable and minimizing waste. Rubber, metal, and plastic are commonly used frames in the construction of these screens, each with its pros and cons. The focus here is on the plastic frame variety, which has showcased numerous benefits in recent years.

Lightweight and Durable

One of the most significant advantages of plastic frame shaker screens is their lightweight nature. Compared to metal frames, plastic frames are considerably lighter, making them easier to handle, transport, and install. This characteristic is particularly beneficial in remote areas where accessibility can be challenging. The reduced weight not only eases the physical burden on workers but also lowers transportation costs.

Despite their lightweight composition, plastic frames exhibit impressive durability. Modern plastic materials are designed to withstand harsh conditions, including extreme temperatures, chemicals, and mechanical stress. This resilience extends the lifespan of the screens, allowing for fewer replacements and, thus, cost savings in the long run. Companies can confidently rely on plastic frame shaker screens to perform consistently, even in demanding environments.

Corrosion Resistance

One major drawback of metal frame shaker screens is their susceptibility to corrosion, particularly in environments that involve exposure to drilling fluids and saline conditions. Corrosion can lead to a degradation of the screen's structure and efficacy, resulting in operational delays and increased maintenance costs. Plastic frames, however, are inherently resistant to corrosion, making them a more reliable choice for prolonged use in various environments.

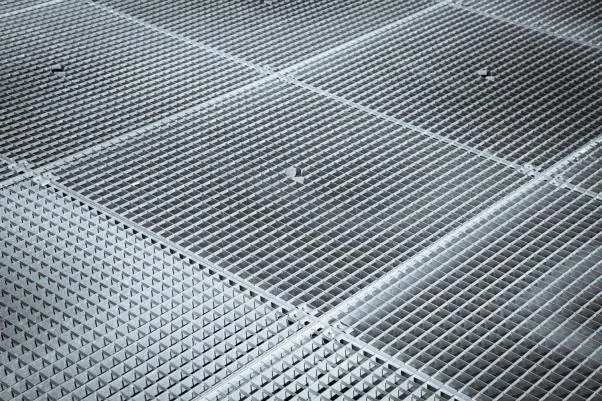

plastic frame shaker screen

Enhanced Separation Efficiency

Plastic frame shaker screens can also provide enhanced separation efficiency compared to their metal counterparts. The design and construction of these screens allow for better fluid flow and more effective particle separation. This characteristic ensures that the drilling fluid remains cleaner and requires less frequent replacement. As a result, drilling companies can maintain optimal performance while decreasing their environmental footprint.

Cost-Effectiveness

When considering the overall lifecycle cost, plastic frame shaker screens can be more economical than metal frames. Although the initial procurement cost may be comparable, the longevity, reduced maintenance expense, and operational efficiency offered by plastic frames ultimately lead to lower costs over time. Companies investing in plastic frame screens often find hidden savings through decreased downtime, fewer repairs, and reduced labor costs associated with handling and replacing screens.

Eco-Friendly Options

With an increasing focus on sustainability in the drilling industry, many manufacturers are producing plastic frame shaker screens using eco-friendly materials. These options not only reduce the ecological impact during production but also promote recycling efforts after their operational life. Companies that adopt such sustainable practices can enhance their corporate image and appeal to environmentally conscious consumers.

Conclusion

In summary, plastic frame shaker screens present a myriad of advantages that make them an attractive option for modern drilling operations. Their lightweight nature, durability, corrosion resistance, enhanced separation efficiency, cost-effectiveness, and eco-friendly potential contribute to their growing popularity in the industry. As companies continue to seek ways to improve operational efficiency while minimizing environmental impact, plastic frame shaker screens will undoubtedly play an essential role in the future of drilling technologies. The ongoing evolution of material science suggests that the development of even more advanced shaker screens is on the horizon, paving the way for improvements in drilling efficiency and sustainability.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025