- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

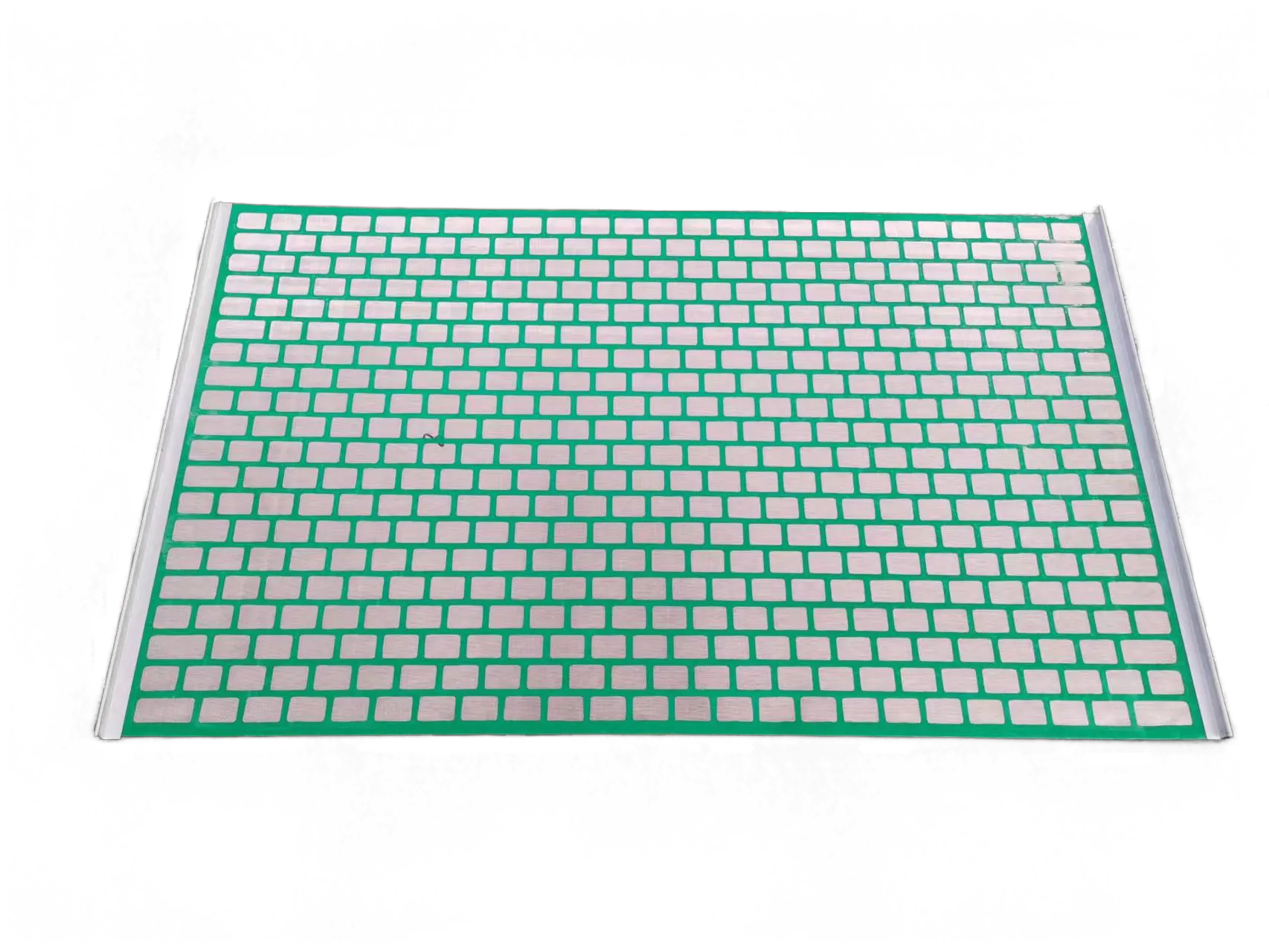

pipeline reinforced mesh

Exploring the Importance of Pipeline Reinforced Mesh in Modern Engineering

In the realm of modern engineering and construction, the utilization of reinforced materials has become a cornerstone for enhancing structural integrity and durability. One such innovative solution is the pipeline reinforced mesh, a material designed to improve the performance and longevity of pipelines across various applications. This article delves into the significance, functionality, and benefits of pipeline reinforced mesh, highlighting its role in contemporary infrastructure projects.

What is Pipeline Reinforced Mesh?

Pipeline reinforced mesh is a specifically designed mesh material that integrates into pipeline systems to offer additional strength, stability, and resistance to various types of external forces. The mesh typically comprises high-strength materials such as steel or polymer composites, which are woven or welded to create a network of interconnected elements. This structure allows it to distribute stress and load more evenly, which is crucial in preventing failures in pipeline systems that operate under high pressure or in extreme environments.

Applications in Structural Engineering

The application of pipeline reinforced mesh spans numerous sectors, including oil and gas, water supply, drainage systems, and construction infrastructure. In the oil and gas industry, reinforced mesh is utilized to protect pipelines from environmental stresses caused by soil movement, temperature fluctuations, and pressure changes. Additionally, in water management systems, the mesh acts as a protective layer that helps prevent the external corrosion of pipelines, thereby reducing maintenance costs and extending the lifespan of these critical systems.

Moreover, in construction, reinforced mesh is often used in the trenches and around pipelines to maintain the integrity of the ground structure. By providing additional support, it prevents soil erosion and minimizes the risk of cave-ins during installation or maintenance processes.

Benefits of Using Reinforced Mesh

pipeline reinforced mesh

1. Enhanced Structural Integrity One of the primary advantages of pipeline reinforced mesh is its ability to bolster the structural integrity of pipelines. The mesh effectively absorbs and distributes loads, reducing the risk of cracks, leaks, or catastrophic failures that could result from excessive pressure.

2. Corrosion Resistance Many types of reinforced mesh are designed to withstand harsh environmental conditions, including humidity, chemicals, and extreme temperatures. This corrosion-resistant quality significantly reduces the need for frequent inspections and repairs, making it a cost-effective solution in the long run.

3. Improved Flexibility The flexibility offered by reinforced mesh allows for easy installation and adaptation during pipeline construction. This characteristic is particularly useful in complex environments where traditional materials may struggle to conform.

4. Safety and Reliability By reinforcing pipelines, the mesh contributes to a safer infrastructure. Stronger pipelines lower the chances of catastrophic failures that could harm workers, damage the environment, or disrupt essential services.

5. Versatility Pipeline reinforced mesh can be engineered to meet specific project requirements, making it suitable for various sizes and types of pipelines. Its adaptability ensures that it can be used in diverse applications, from small residential plumbing systems to large-scale industrial pipelines.

Conclusion

As the world continues to evolve and urbanize, the demand for robust infrastructure systems will only increase. Pipeline reinforced mesh stands out as a vital material that enhances the strength, durability, and reliability of pipeline systems across multiple industries. By incorporating this innovative mesh into engineering projects, stakeholders can ensure the longevity of their pipelines, save on maintenance costs, and contribute to a safer working environment.

In summary, the integration of pipeline reinforced mesh into modern engineering practices not only addresses current infrastructural challenges but also paves the way for sustainable and resilient future developments. As technology continues to advance, materials like reinforced mesh will play an essential role in shaping the infrastructure of tomorrow, providing solutions that meet the rigorous demands of a rapidly changing world.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025