- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Enhanced Reinforcement Solutions for Pipeline Mesh Structures and Their Applications

Understanding Pipeline Reinforced Mesh Applications and Benefits

In the world of civil engineering and construction, the structural integrity and reliability of a project are paramount. One of the methods employed to ensure strength, especially in pipelines, is the utilization of reinforced mesh. Pipeline reinforced mesh combines the durability of traditional reinforcement techniques with the unique needs of pipeline construction. This article will delve into what pipeline reinforced mesh is, its benefits, and its applications.

What is Pipeline Reinforced Mesh?

Pipeline reinforced mesh is a type of steel reinforcement that consists of a grid of interwoven steel bars or wires. This mesh is particularly designed to support pipeline installations, enhancing their tensile strength and ductility. The design is adaptable and can be tailored to suit specific project requirements, ensuring that the mesh can withstand various environmental conditions that pipelines may encounter.

Benefits of Pipeline Reinforced Mesh

1. Enhanced Structural Integrity One of the primary benefits of using reinforced mesh is the significant improvement in structural integrity. The mesh provides additional support to pipelines, especially in areas that are prone to stress from soil shifting and environmental factors.

2. Durability Reinforced mesh is typically made of high-quality steel which is resistant to corrosion and wear. This durability is essential for pipelines that carry fluids in demanding environments, such as beneath roads or in regions with severe weather conditions.

3. Cost-Effectiveness While the initial investment in reinforced mesh may be higher than conventional methods, its longevity and ability to reduce maintenance costs make it a cost-effective choice over time. By minimizing the need for repairs and replacements, project managers can save on overall project expenses.

4. Versatility Pipeline reinforced mesh can be used in various applications, including water supply systems, sewage systems, and even in gas pipelines. Its adaptability means it can be integrated into different pipeline designs and configurations, making it a practical choice for diverse projects.

5. Ease of Installation The mesh can be produced in sheets or rolls, making it easier to handle and install on-site. This reduces labor costs and time, allowing for quicker project completion without sacrificing quality.

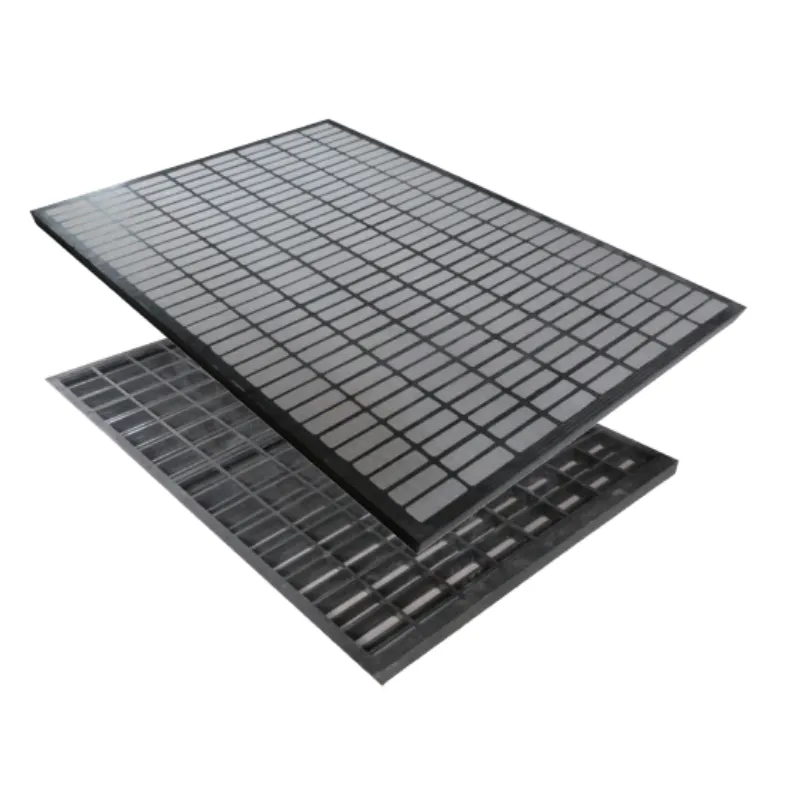

pipeline reinforced mesh

Applications of Pipeline Reinforced Mesh

The applications of pipeline reinforced mesh are extensive

. Here are some key areas where it is commonly utilized1. Water and Sewer Systems In municipal projects, reinforced mesh is used in the construction of underground water and sewage systems. The added support helps resist pressures from soil and water while ensuring a reliable flow.

2. Industrial Pipelines For industries that require pipelines to transport chemicals, petroleum, or gases, reinforced mesh provides the necessary reliability. The mesh can hold up against the heavy weights and harsh conditions that often accompany industrial applications.

3. Transportation Infrastructure As pipelines often run beneath or alongside major roads and transportation routes, reinforced mesh serves as a protective layer. It minimizes the risk of collapse or damage, which can disrupt traffic and lead to costly repairs.

4. Residential Developments In residential construction, the use of reinforced mesh in pipelines can improve the longevity and reliability of home plumbing systems, offering peace of mind to homeowners regarding their water supply.

5. Environmental Projects Pipeline reinforced mesh is also employed in environmental applications, such as drainage systems designed to prevent flooding. Its structural benefits help maintain the integrity of these crucial systems.

Conclusion

Pipeline reinforced mesh is a revolutionary approach to enhancing the strength and reliability of pipeline systems across various applications. Its benefits, including improved structural integrity, durability, cost-effectiveness, versatility, and ease of installation, make it an invaluable asset in modern construction projects. As the demand for efficient and robust pipeline systems continues to grow, the use of reinforced mesh will undoubtedly play a vital role in meeting these needs. By understanding its applications and advantages, engineers and project managers can make informed decisions to optimize their projects, ensuring safety and longevity in pipeline installations.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025