- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

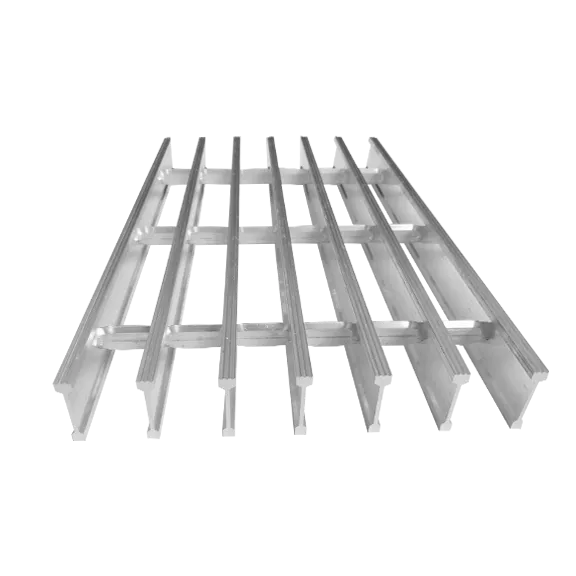

pipeline reinforced mesh

Understanding Pipeline Reinforced Mesh A Comprehensive Overview

In the modern construction and engineering landscape, the need for robust and efficient infrastructure is paramount. One of the emerging materials that have gained traction in recent years is the pipeline reinforced mesh. This innovative construction solution is increasingly being employed in various applications, from civil engineering to industrial projects, due to its numerous advantages.

What is Pipeline Reinforced Mesh?

Pipeline reinforced mesh is a specialized type of reinforcement used primarily to enhance the structural integrity of concrete and other materials. It consists of a network of steel or composite fibers arranged in a grid pattern, which is then embedded in concrete or other building materials. The primary purpose of this mesh is to distribute loads evenly, provide tensile strength, and prevent cracking or deformation in structures.

Advantages of Using Pipeline Reinforced Mesh

1. Enhanced Structural Strength One of the most significant benefits of using pipeline reinforced mesh is its ability to provide superior structural strength. The mesh helps to withstand various loads and stresses, making it ideal for use in critical infrastructure such as bridges, highways, and buildings.

2. Durability and Longevity Structures reinforced with this mesh are generally more durable than those that rely solely on conventional reinforcement methods. The interconnected fibers in the mesh help to mitigate the risks of cracking and deterioration over time, leading to longer-lasting buildings and infrastructure.

3. Cost-Effectiveness While the initial investment in pipeline reinforced mesh might be higher than traditional reinforcement methods, the long-term benefits often outweigh the costs. Reduced maintenance and repair needs due to the material's durability can lead to significant savings over the lifespan of a structure.

pipeline reinforced mesh

4. Ease of Installation Pipeline reinforced mesh is relatively easy to handle and install compared to traditional rebar systems. Its lightweight nature and flexibility allow for quicker setups, reducing labor costs and time on site. Additionally, the mesh can be cut to size with ease, enabling customization for specific projects.

5. Corrosion Resistance Many pipeline reinforced meshes are designed to resist corrosion, which is critical in environments prone to moisture or chemical exposure. This resistance contributes to the longevity of the structures and reduces the need for frequent repairs and replacements.

6. Environmental Considerations As the construction industry increasingly focuses on sustainability, pipeline reinforced mesh presents an eco-friendlier alternative. Many options are made from recycled materials, and their durability means that structures require fewer resources over time, minimizing the overall environmental impact.

Applications of Pipeline Reinforced Mesh

The versatility of pipeline reinforced mesh allows it to be used in various applications. Here are some areas where it is particularly useful

- Concrete Pavements The mesh provides additional support to concrete streets and highways, helping to reduce cracking and maintenance costs. - Building Foundations In residential and commercial constructions, the mesh ensures that foundations can bear heavy loads without significant wear and tear. - Retaining Walls The added strength of the mesh makes it an ideal reinforcement solution for walls that need to hold back earth and water, enhancing stability. - Precast Concrete Products The mesh can be integrated into precast concrete products, such as panels and blocks, providing additional strength for modular construction.

Conclusion

Pipeline reinforced mesh stands out as a modern solution that meets the demands of contemporary construction and infrastructure projects. Its advantages, including enhanced strength, durability, cost-effectiveness, and ease of installation, make it a popular choice among engineers and builders alike. As the industry continues to evolve, embracing innovative materials like pipeline reinforced mesh will be crucial in creating resilient and sustainable structures that stand the test of time. Whether in urban development or industrial applications, the integration of this advanced reinforcement technology promises to significantly improve the quality and longevity of our built environment.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025