- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Reinforced Mesh Solutions for Pipeline Strength and Durability Enhancement

The Importance of Pipeline Reinforced Mesh in Modern Infrastructure

In today's rapidly evolving industrial landscape, the design and construction of pipelines play a crucial role in various sectors, including oil and gas, water supply, and drainage systems. With the increasing demand for safety, reliability, and efficiency in these systems, the use of advanced materials has become essential. One such material that has gained significant attention is pipeline reinforced mesh. This innovative solution not only enhances the structural integrity of pipeline installations but also contributes to the longevity and performance of the systems in which it is utilized.

Understanding Pipeline Reinforced Mesh

Pipeline reinforced mesh, often constructed from high-strength steel or synthetic materials, serves as a skeletal framework designed to provide additional support to pipelines. This mesh is engineered to distribute loads evenly along the structure, thereby minimizing the risk of deformation or failure under stress. By reinforcing pipes with a mesh, engineers can significantly improve the overall performance and durability of the pipeline system.

Applications of Reinforced Mesh in Pipelines

Reinforced mesh is employed across various applications, with key sectors benefiting from its use

1. Oil and Gas Industry The oil and gas sector frequently utilizes pipeline reinforced mesh in their operations to transport hydrocarbons safely. Given the high pressures and potential hazards associated with these materials, reinforced mesh helps ensure that pipelines can withstand the rigors of day-to-day use while minimizing the risk of leaks and ruptures.

2. Water Supply Systems In municipal water supply networks, reinforced mesh is crucial for ensuring the structural integrity of pipelines over long distances. As these systems must endure various environmental forces, including soil movement and hydraulic pressure changes, the added support provided by reinforced mesh helps maintain the operational efficiency and reliability of water delivery.

3. Drainage and Waste Management In waste management systems, reinforced mesh can enhance the stability of pipelines carrying wastewater or stormwater. The mesh provides added strength that can prevent collapses and blockages, thus improving the overall effectiveness of the drainage system.

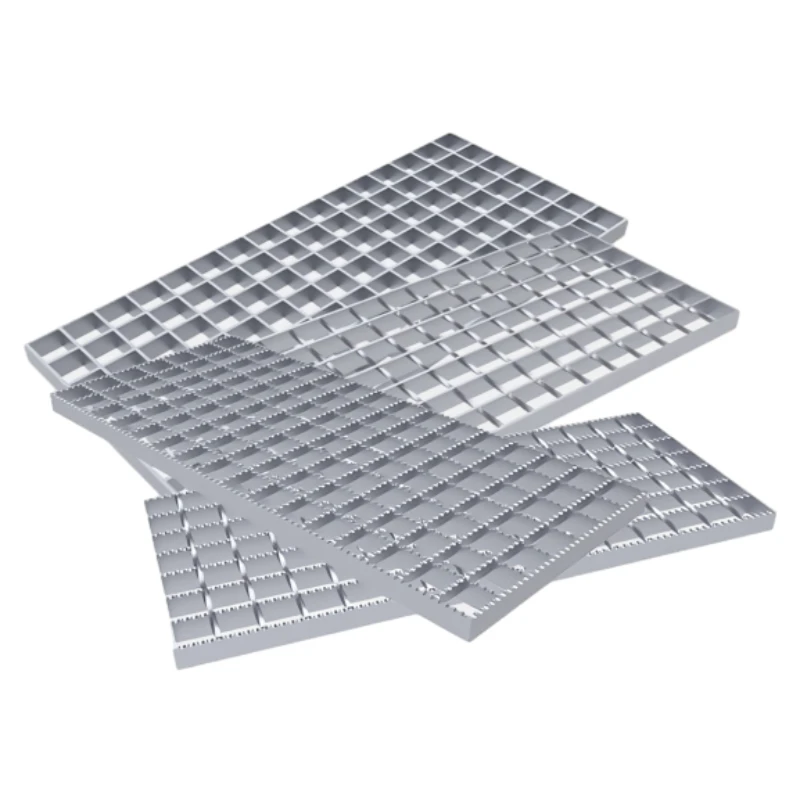

pipeline reinforced mesh

Benefits of Using Pipeline Reinforced Mesh

The incorporation of reinforced mesh in pipelines presents several key advantages

1. Enhanced Load Distribution One of the primary benefits of using reinforced mesh is its ability to evenly distribute loads along the pipeline. This reduces localized stresses that can lead to failures, ensuring that the pipeline maintains its structural integrity under varying conditions.

2. Increased Longevity With enhanced support, pipelines reinforced with mesh tend to have extended lifespans. This durability minimizes the need for frequent repairs or replacements, leading to reduced maintenance costs over time.

3. Improved Safety The added strength provided by reinforced mesh decreases the likelihood of catastrophic failures, thereby enhancing overall safety for both the infrastructure and the surrounding environment. This is especially critical in industries where hazardous materials are transported.

4. Cost-Effectiveness Although there may be initial costs associated with incorporating reinforced mesh into pipeline designs, the long-term savings from reduced maintenance and increased durability often outweigh these expenses. Moreover, the investment in reinforced mesh technology may result in fewer disruptions in service, benefiting businesses and communities reliant on these essential systems.

Conclusion

As industries continue to evolve, the importance of innovative materials and design solutions becomes ever more apparent. Pipeline reinforced mesh stands out as a significant advancement in ensuring the safety, reliability, and efficiency of pipeline infrastructures. With its versatile applications spanning the oil and gas sector, water supply systems, and drainage management, reinforced mesh is poised to play a critical role in shaping the future of pipeline engineering. By prioritizing robust materials like reinforced mesh, we can build a more resilient infrastructure capable of meeting the demands of a modern world while safeguarding our vital resources.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025