- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

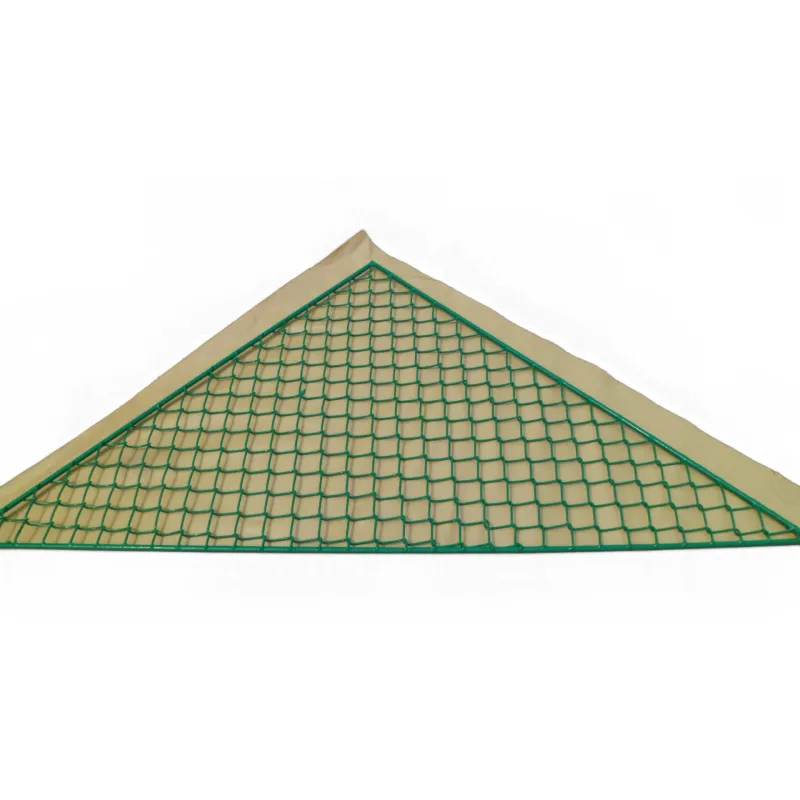

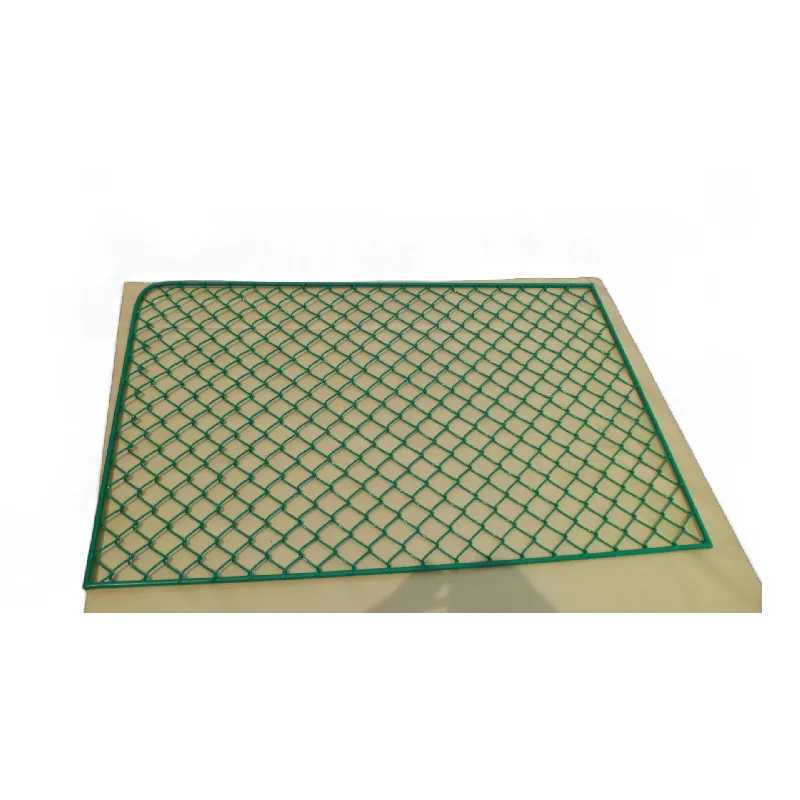

Perimeter Net – Durable, UV-Stable, Custom Safety Netting

Chain Link Helipad Perimeter Safety Netting: what’s changing on the edge of the deck

The first time I saw a rooftop helipad fitted with a chain-link [Perimeter Net], it looked almost too tidy for such a rough-duty job. But that’s the trend: more hospitals, energy sites, and offshore assets are swapping improvised rails for engineered, certified perimeter systems that stop tools—and people—from going overboard.

This product—Chain Link Helipad Perimeter Safety Netting—comes out of the industrial zone south of Anping Town, Hengshui, Hebei, China. If you follow wire mesh, you already know Anping is the world’s workshop for this stuff. And to be honest, that shows in the fit-and-finish.

Industry pulse: why chain link on helipads now?

Regulators keep pushing for continuous outboard protection, minimal snag risk, and proven corrosion resistance. Offshore, operators still cite CAP 437; onshore, it leans ICAO and FAA. Chain-link perimeter assemblies hit a sweet spot: predictable strength, easy inspection, and repeatable installations. Many customers say upkeep is simpler than fabric rope nets, especially where wind-driven grit chews up fibers.

Typical applications

- Hospital and commercial rooftop helipads (urban wind exposure).

- Energy and industrial helidecks (refinery, petrochemical, O&G).

- Ship and offshore platform decks where authority accepts chain-link.

- Temporary test pads and training facilities.

Product specifications (core model)

| Parameter | Spec (typ.) |

|---|---|

| Mesh aperture | ≈ 50–60 mm diamond |

| Wire diameter | 3.2–4.0 mm (ASTM A392 Class 2 or SS316) |

| Frame/stanchion height | ≈ 1.1–1.5 m above deck (per project) |

| Finish | HDG to ISO 1461 (≈ 70–100 µm) or SS316; optional powder coat |

| Edge treatment | Selvage knuckled or twisted; lashed to frame with SS ties |

| Service life | 10–15 years offshore; 15+ onshore (real-world use may vary) |

| Cert/Docs | Mill certs, CoC, MTC, NACE/paint DFT reports on request |

How it’s made (short version)

Materials: low-carbon steel wire (galvanized) or SS316; structural angles/tubes for frames. Methods: chain-link weaving → panel cutting → edge binding → hot-dip galvanizing or passivation → powder coating (optional) → mock assembly. Testing: zinc thickness (ISO 1461), mesh tensile (ASTM A392), salt spray (ASTM B117), weld/MPI on frames, torque checks on clamps. Final QA includes gauge verification and fit-up. I guess that’s why site installs tend to go quickly.

Real-world advantages

- Predictable rigidity with minimal rebound, reducing “slingshot” risk compared with loose textiles.

- Fast inspection—damage and corrosion are visible at a glance.

- Modular panels; easy swap-out without shutting the deck for days.

- Compliance mapping to CAP 437/ICAO layouts, subject to local AHJ acceptance.

Feedback? One facilities manager told me, “We’ve had fewer tool-escape incidents since switching to [Perimeter Net] panels—wind days used to be our pain point.”

Vendor comparison (snapshot)

| Vendor | Standards mapping | Lead time | Customization |

|---|---|---|---|

| HF Petro Mesh (Anping) | CAP 437, ICAO, FAA refs; ASTM/ISO material certs | 4–8 weeks | Aperture, height, coating, clamps, radius |

| Generic Importer | Basic ASTM only | 8–12 weeks | Limited sizes/colors |

| Local Fabricator | Varies; needs engineering sign-off | 2–6 weeks | High, but QA depends on shop |

Case note: coastal energy site

A Southeast Asia refinery upgraded to [Perimeter Net] panels: 1.2 m height, 60 mm mesh, HDG + RAL 6005 topcoat. Drop objects log fell by 31% in the first year; salt-spray coupons showed

Notes on compliance and selection

Always align geometry (height, overhang, slope) and load capacity with your authority having jurisdiction. CAP 437 and ICAO outline continuous perimeter protection and impact performance; FAA ACs guide U.S. rooftop layouts. Materials-wise, HDG works for most climates; SS316 is preferred in severe marine zones.

Ordering checklist

- Deck radius and corner geometry; door/ladder clearances.

- Mesh aperture and wire gauge; HDG vs SS316; color.

- Clamp pattern, fastener alloy, earthing/bonding plan.

- Test package: ISO 1461 DFT, ASTM B117 hours, tensile certs.

Authoritative references:

- UK CAA, CAP 437: Offshore Helicopter Landing Areas—Guidance on Standards.

- ICAO Annex 14, Volume II: Heliports.

- FAA AC 150/5390-2C: Heliport Design.

- ISO 1461: Hot dip galvanized coatings—zinc coating on fabricated iron and steel articles.

- ASTM A392: Specification for Zinc-Coated Steel Chain-Link Fence Fabric.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025