- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

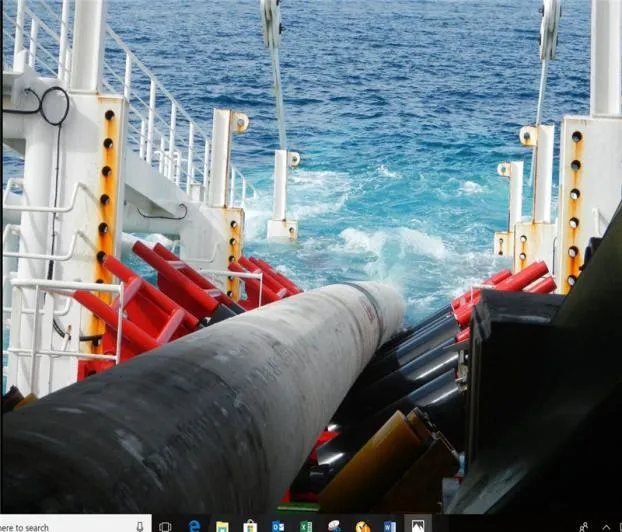

Offshore Pipeline Counterweight Using Welded Wire Mesh for Enhanced Stability and Support

The Role of Welded Wire Mesh in Offshore Pipeline Counterweights

In the offshore oil and gas industry, the stability and safety of pipelines are of paramount importance. One of the innovative solutions that have emerged to address the challenges posed by underwater currents and environmental factors is the use of welded wire mesh as counterweights for offshore pipelines. This article will explore the significance of welded wire mesh in the context of offshore pipeline installations, its construction, benefits, applications, and future prospects.

Understanding Offshore Pipelines

Offshore pipelines are vital components in the transportation of oil and gas from extraction sites to processing facilities. They are often laid on the seabed or buried in the sediment, exposed to various natural forces such as waves, currents, and sediment movement. To maintain their integrity and functionality, these pipelines require effective support systems that can counteract the dynamic forces acting upon them.

The Concept of Counterweights

Counterweights serve to stabilize pipelines, preventing them from floating or shifting under the influence of environmental forces. Welded wire mesh has emerged as a preferred material for this application due to its strength, flexibility, and durability. It consists of a grid of wires that are welded at their intersections, forming a robust yet lightweight structure that can be easily molded to fit the requirements of specific pipeline installations.

Construction of Welded Wire Mesh

Welded wire mesh is typically made from high-strength steel or other corrosion-resistant materials. The process of manufacturing welded wire mesh involves drawing wires from metal rods, followed by cutting and forming them into grids before welding at the intersections. This results in a product that can withstand substantial tensile and compressive forces while maintaining a lightweight profile, making it ideal for underwater applications where weight and drag are significant considerations.

Benefits of Welded Wire Mesh in Offshore Applications

1. Strength and Durability One of the foremost advantages of welded wire mesh is its inherent strength. The welded intersections provide higher load-bearing capacity compared to simpler mesh forms, making it suitable for application in harsher environments.

offshore pipeline counterweight welded wire mesh

2. Corrosion Resistance In offshore environments, materials are subjected to saline water and other corrosive elements. Welded wire mesh can be coated with protective finishes, enhancing its resistance and extending its service life.

3. Adaptability Welded wire mesh can be manufactured in various shapes and sizes, allowing it to be tailored to fit specific pipeline configurations. This adaptability ensures optimal performance and stability.

4. Cost-Effectiveness The production process of welded wire mesh is relatively efficient, resulting in lower material costs compared to alternative stabilization solutions. Its long lifespan further contributes to overall lifecycle savings.

5. Ease of Installation The lightweight nature of welded wire mesh allows for easier handling and installation on-site, which can significantly reduce labor costs and enhance project timelines.

Applications in Offshore Projects

Welded wire mesh is employed as counterweights in various offshore pipeline projects worldwide. For instance, it is often used in conjunction with sandbags or concrete weights to anchor pipelines securely to the seabed. Additionally, it can be used in marine construction projects, including platforms and anchors, where stability and resistance to tidal forces are critical.

Future Prospects

As the offshore oil and gas industry continues to explore deeper waters and more challenging environments, the demand for innovative stabilization solutions like welded wire mesh is likely to grow. Ongoing research and development efforts aim to improve the properties of welded wire mesh, potentially integrating advanced materials and technologies that can further enhance its performance in adverse conditions.

In conclusion, welded wire mesh plays a crucial role in the offshore pipeline industry, providing effective counterweight solutions that enhance stability and safety. As the industry evolves, the continued innovation in materials and construction techniques will ensure that welded wire mesh remains an integral component of offshore infrastructure for years to come.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025