- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

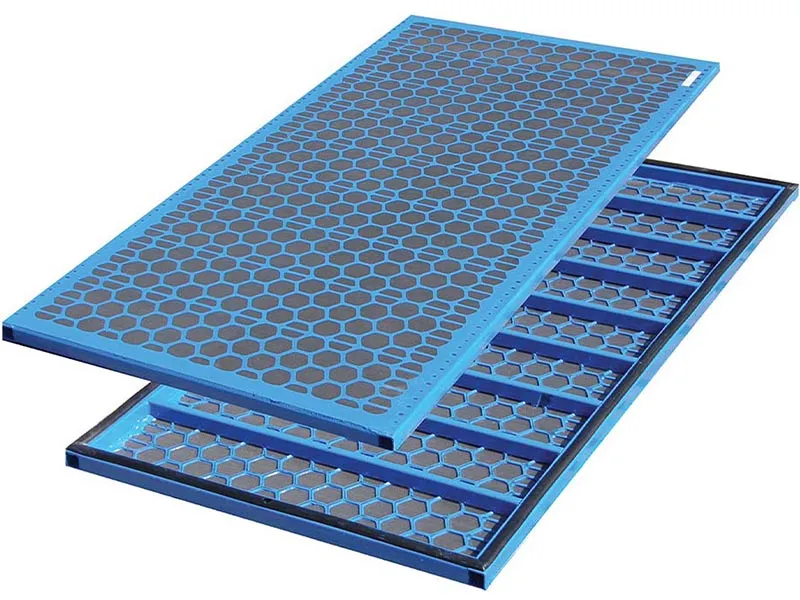

non serrated grating

Non-Serrated Grating An Overview of Applications and Innovations

Grating is a fundamental optical component used in various scientific and engineering fields. Among the different types of gratings, non-serrated gratings are of particular interest due to their unique properties and versatile applications. Unlike serrated gratings, which have raspy or sharp-edged profiles, non-serrated gratings feature smooth, continuous lines that allow for varied optical functions with minimal light scattering from the grating surface. This article explores the characteristics, manufacturing techniques, and applications of non-serrated gratings, highlighting their significance in modern technology.

Characteristics of Non-Serrated Gratings

Non-serrated gratings are characterized by their regular, sine-wave, or linear profiles that produce light diffraction without substantial interruption of the wavefront. One of the primary advantages of non-serrated gratings is their ability to achieve high efficiency in light diffraction. The smoothness of the grating surface minimizes scattering and unwanted diffraction orders, ensuring that a higher proportion of incident light is directed into the desired output beam.

Additionally, non-serrated gratings can be produced with varying groove densities, allowing for customization tailored to specific applications. The spacing and depth of the grooves play crucial roles in determining the wavelength-specific response of the grating, making them highly adaptable to various optical requirements. Their broad wavelength range, from ultraviolet to infrared, makes non-serrated gratings a universal tool in spectroscopic applications.

Manufacturing Techniques

The manufacturing process of non-serrated gratings involves several advanced techniques. One of the most common methods is photolithography, where a light-sensitive material is patterned to create the grating structure. This process allows for precise control over groove dimensions and spacing, further ensuring high efficiency and optimal diffraction characteristics.

Another promising technique is the use of laser writing systems. This method utilizes focused laser beams to etch the grating pattern onto a substrate material. Laser writing offers the advantage of being able to create complex structures with high precision while maintaining the non-serrated profile. Moreover, it can be employed to manufacture gratings on a variety of substrates, including glass, silicon, and polymers, enhancing the versatility of non-serrated grating designs.

Applications of Non-Serrated Gratings

Non-serrated gratings find their relevance in numerous applications across different fields

non serrated grating

1. Spectroscopy These gratings are widely used in spectrometers for analyzing the spectral composition of light. Their ability to produce sharp and distinct diffraction patterns makes them ideal in scientific research, environmental monitoring, and pharmaceuticals.

2. Optical Communications In the realm of telecommunications, non-serrated gratings play a crucial role in wavelength division multiplexing (WDM) systems. Their capability to efficiently separate different wavelengths allows for increased data transmission capacities.

3. Laser Systems Lasers often use non-serrated gratings as wavelength selectors to ensure the output is confined to specific frequencies. This quality is essential for precision applications in medicine, manufacturing, and scientific research.

4. Imaging Systems Non-serrated gratings are increasingly used in imaging applications, such as optical coherence tomography (OCT). Their smooth profiles help in obtaining clearer images with reduced artifacts, enhancing diagnostic procedures.

5. Metrology In metrology, non-serrated gratings are employed for measuring optical properties. Their ability to deliver consistent and accurate measurements makes them indispensable in calibrations.

Future Innovations

As the demand for more advanced optical components grows, the development of non-serrated gratings is expected to continue evolving. Innovations might involve the integration of nanotechnology, allowing for the creation of ultra-compact and highly efficient gratings. Additionally, research is underway to develop adaptive gratings that can change their properties in real-time, potentially revolutionizing fields like optical communication and sensor technology.

Conclusion

Non-serrated gratings are pivotal components in a variety of optical applications, bridging gaps in technology with their efficiency and adaptability. As manufacturing techniques advance and new applications are discovered, the significance of non-serrated gratings is set to expand, making them an integral aspect of contemporary and future optical systems. Their ability to facilitate precise control over light makes them not only a tool of the present but also a cornerstone for future innovations across multiple industries.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025