- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

metal grating weight

Understanding Metal Grating Weight Factors, Calculations, and Applications

Metal grating is a commonly used structural element in various industries, serving as a platform for walkways, stairs, drainage systems, and industrial flooring. One of the critical factors that engineers and architects must consider when selecting metal grating is its weight. The weight of metal grating plays a significant role in determining its application, structural integrity, and ease of installation. This article aims to provide an overview of the factors influencing metal grating weight, methods to calculate it, and some of its key applications.

Factors Influencing Metal Grating Weight

1. Material Type The choice of material significantly affects the weight of the grating. Common materials used for metal grating include steel, aluminum, and fiberglass. Steel grating is typically heavier but is known for its strength and durability, making it suitable for heavy industrial applications. Aluminum grating, on the other hand, is lighter and often used in areas where weight reduction is critical.

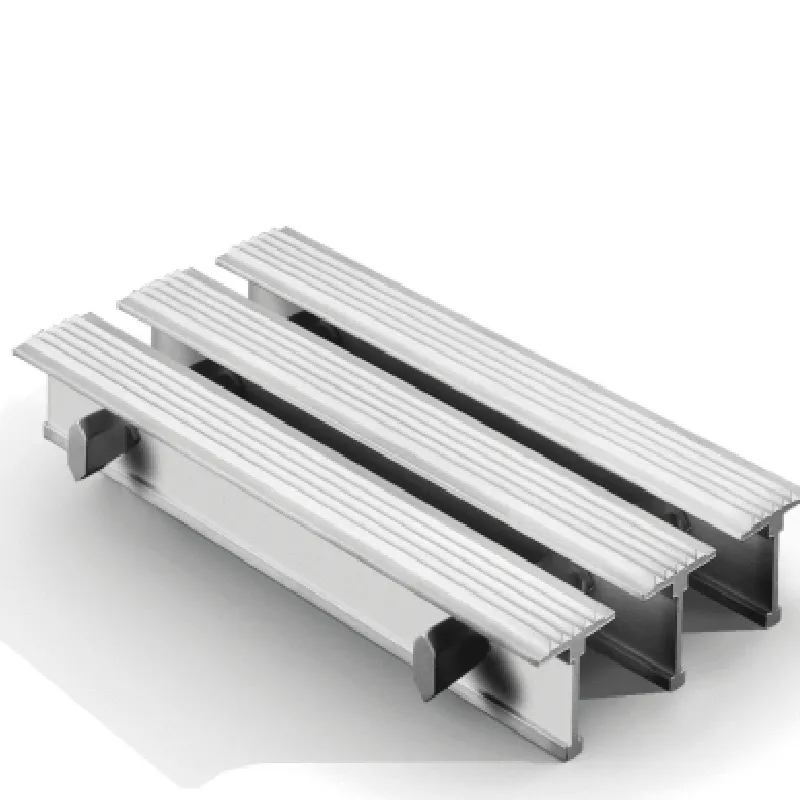

2. Grating Type There are various types of metal grating, including welded, swage-locked, and press-locked gratings. Each type has a unique manufacturing process that influences its weight. For example, welded grating tends to be heavier due to the additional material used in the welding process, whereas swage-locked grating can be lighter due to its less bulky design.

3. Bar Size and Spacing The dimensions of the individual bars and the spacing between them also impact the total weight. Thicker bars will contribute more weight to the grating, while wider spacing can lead to a reduction in weight but may compromise load-bearing capacity. Engineers must balance these factors to ensure both performance and structural integrity.

4. Surface Treatment Metal gratings are often coated or treated to enhance their durability and resistance to corrosion. Processes such as galvanization, powder coating, or anodizing can add to the overall weight of the grating. While these treatments are essential for longevity, they should be considered when calculating the total weight.

Calculating Metal Grating Weight

To accurately determine the weight of metal grating, one must consider its material density, dimensions, and configuration. The basic formula to calculate the weight of the grating is

\[ \text{Weight} = \text{Volume} \times \text{Density} \]

Where volume can be calculated based on the individual elements of the grating

metal grating weight

1. Volume Calculation The volume of a single bar can be calculated as \[ \text{Volume} = \text{Length} \times \text{Width} \times \text{Height} \] If there are multiple bars, the total volume can be calculated by multiplying the volume of one bar by the number of bars.

2. Density The density of the material (usually expressed in kg/m³) can be found in material property tables.

As an example, if you have a steel grating with bars that are 25 mm wide, 5 mm thick, and 1 meter long, and you want to calculate the weight for 10 such bars, the weight calculation process would be as follows

1. Calculate the volume of one bar \[ \text{Volume} = 1 \text{m} \times 0.025 \text{m} \times 0.005 \text{m} = 0.000125 \text{m}^3 \]

2. Multiply by the number of bars \[ \text{Total Volume} = 0.000125 \text{m}^3 \times 10 = 0.00125 \text{m}^3 \]

3. Use the density of steel (approximately 7850 kg/m³) \[ \text{Weight} = 0.00125 \text{m}^3 \times 7850 \text{kg/m}^3 \approx 9.8125 \text{kg} \]

By following this method, one can precisely estimate the weight of metal grating for specific applications.

Applications of Metal Grating

Metal grating finds extensive use across various industries, including construction, transportation, and manufacturing. For instance, in industrial settings, heavy-duty steel grating is utilized for flooring and platforms due to its high load-bearing capacity. In pedestrian areas, lightweight aluminum grating is favored for walkways and bridges as it permits easier transportation and installation. Additionally, grating is crucial in drainage systems to allow water flow while providing a sturdy surface for movement.

In conclusion, understanding the factors influencing metal grating weight is essential for selecting the right type for a specific application. By calculating its weight accurately, engineers and architects can ensure that their designs meet safety standards and functional requirements, ultimately leading to safer and more efficient structures.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025