- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

metal grating sizes

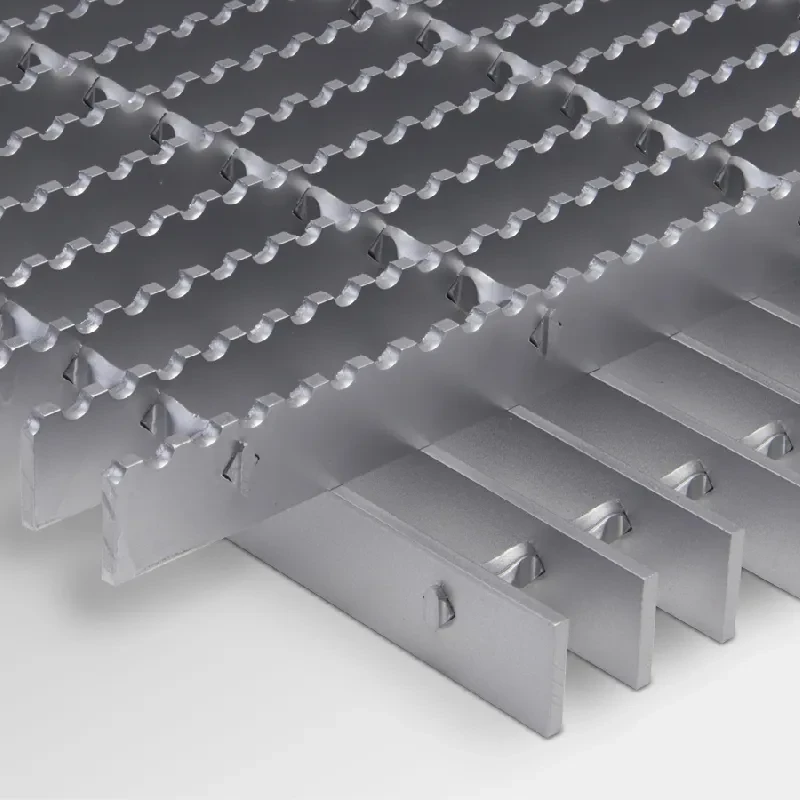

Understanding Metal Grating Sizes A Comprehensive Guide

Metal gratings are integral components utilized in various industries, including construction, manufacturing, and infrastructure. They serve multiple purposes, such as providing safety, facilitating drainage, and enabling ventilation. With functionality being the core aspect, the size of metal grating is equally important as it determines the operational efficiency and safety of the application. In this article, we delve into the significance of metal grating sizes and considerations for selecting the appropriate dimensions.

What is Metal Grating?

Metal grating refers to a framework of bars or rods that are arranged to create a grid-like structure. Common materials for metal gratings include steel, aluminum, and stainless steel, chosen for their strength, durability, and resistance to various environmental conditions. Metal gratings can be categorized into several types, such as welded, riveted, and molded, based on the manufacturing process, yet size remains a critical contributing factor across all types.

Importance of Size in Metal Grating

1. Load Requirements Different applications require a specific load capacity. For instance, industrial settings may necessitate heavy-duty grating capable of supporting the weight of machinery, equipment, and personnel. Conversely, pedestrian walkways may only need lighter gratings. The size of the bars, spacing between them, and overall dimensions of the grating must be carefully considered to meet these load requirements.

2. Safety Standards Grating sizes also play an essential role in adhering to safety standards. Proper spacing between bars is crucial to prevent accidents, especially in environments where fall protection is pertinent. Depending on the application, regulations may dictate maximum allowable spacing, especially in areas with foot traffic or where tools and materials may fall through the gaps.

3. Ventilation and Drainage In applications involving ventilation and drainage systems, the size of the grating affects airflow and water flow rates. The dimensions and spacing need to be optimized to ensure that as much air or water can pass through as needed, preventing clogs and maintaining system efficiency.

4. Installation and Maintenance The size of metal gratings also impacts installation processes. Larger gratings may be more difficult to maneuver and install, particularly in confined or hard-to-reach spaces. Smaller sizes may be easier to handle but could require more fasteners and additional supports. Maintenance considerations are equally important; larger gratings might require more substantial support systems while smaller ones may need more frequent replacement.

metal grating sizes

Choosing the Right Size

When selecting the appropriate size for metal grating, several factors need to be taken into account

- Application Type Understand the end use of the grating. Industrial applications usually warrant heavier, more robust designs, whereas residential or pedestrian applications might allow for lighter options.

- Environmental Conditions Consider the environment where the grating will be installed. Areas with heavy moisture may require gratings with protective coatings or materials that resist corrosion.

- Design Specifications Consult with engineers or design professionals to determine the right width, height, and spacing based on the load requirements and safety protocols.

- Manufacturing Standards Familiarize yourself with applicable manufacturing and safety standards to ensure compliance. The American National Standards Institute (ANSI) and other bodies provide guidelines on grating fabrication and installation.

Conclusion

In summary, understanding metal grating sizes is pivotal for ensuring safety, efficiency, and functionality across various applications. Whether for industrial, commercial, or residential uses, careful consideration of load requirements, safety standards, and installation challenges will lead to more effective and secure grating solutions. As industries continue to evolve, keeping abreast of innovations and best practices in metal grating design and sizing will remain essential for safety and operational effectiveness.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025