- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

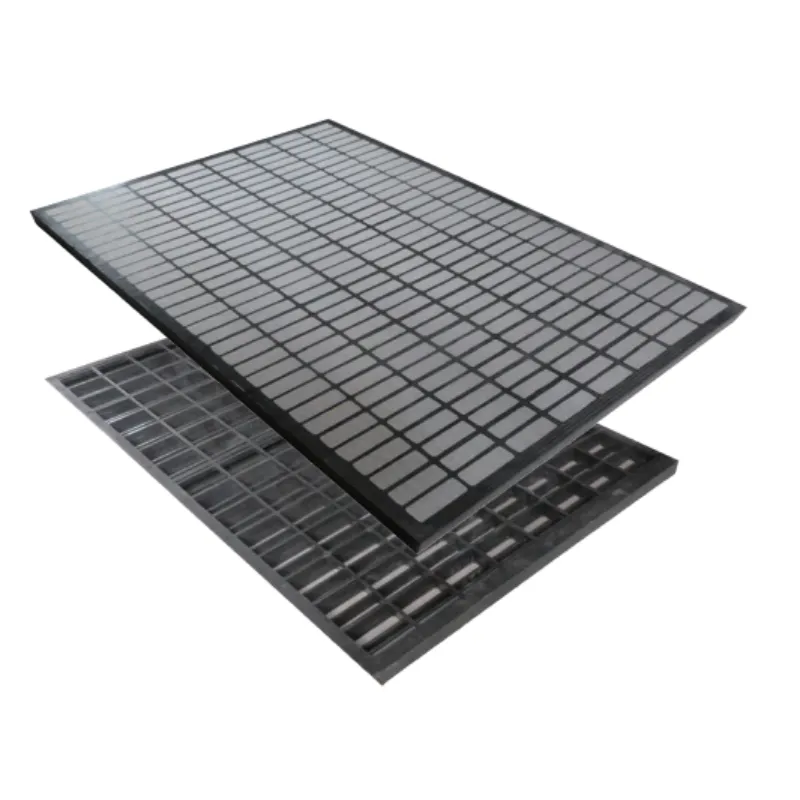

Metal Grating Panels for Durable and Versatile Construction Solutions

The Benefits and Applications of Metal Grating Panels

Metal grating panels have emerged as an indispensable material in various industrial and commercial applications due to their durability, strength, and versatility. Comprised of a series of parallel bars or rods with openings that allow for drainage and light penetration, these panels are often fabricated from steel, aluminum, or other metals, making them suitable for a wide range of environments.

Strength and Durability

One of the primary features of metal grating panels is their exceptional strength and load-bearing capabilities. They are designed to withstand heavy weights and intense wear, making them ideal for applications in factories, warehouses, and outdoor environments. Unlike plastic or wooden alternatives, metal grating panels are resistant to corrosion and weathering, significantly extending their lifespan. This durability means they require less frequent replacement or maintenance, ultimately leading to cost savings for businesses.

Safety and Traction

In areas where slip hazards exist, such as walkways, staircases, and industrial workspaces, metal grating panels provide an excellent solution. The openings in the grating enhance traction, reducing the likelihood of falls and injuries. Many metal grating panels also feature additional surface treatments, such as serrated or surface-treated finishes, to further improve grip. This safety feature is particularly crucial in environments where water, oil, or other slippery substances are present.

Versatile Applications

Metal grating panels are incredibly versatile and can be used in numerous applications across various industries. In construction, they are commonly employed as flooring for catwalks and platforms, allowing for easy access to machinery while ensuring safety. In the manufacturing sector, these panels serve as walkways in assembly lines and production areas. Their strength and ability to support heavy loads make them ideal for use in loading docks and storage facilities.

metal grating panels

Additionally, metal grating panels are extensively used in the oil and gas industry, where they facilitate safe access over pipelines and other facilities while allowing for drainage and airflow. Furthermore, they are prevalent in water treatment plants, where corrosion-resistant properties are essential due to exposure to harsh chemicals and environments.

Aesthetic Options

While functionality is the primary concern, aesthetics also play a significant role in the selection of materials for many projects. Metal grating panels are available in various designs, finishes, and colors, allowing them to be integrated into architectural projects smoothly. Whether used in commercial buildings, urban installations, or public transportation systems, metal grating can enhance the visual appeal of a structure while maintaining its practical functionalities.

Environmental Considerations

As sustainability becomes increasingly important in material selection, metal grating panels stand out for their recyclability. Metals such as aluminum and steel can be recycled multiple times without degrading their quality, making them an eco-friendly choice. This feature aligns with the growing trend of using sustainable materials in construction and industrial applications.

Conclusion

In conclusion, metal grating panels are a vital component in modern construction and industrial design. Their exceptional strength, safety features, versatility in application, aesthetic adaptability, and environmental friendliness make them a top choice for a wide range of needs. As industries continue to evolve, the demand for innovative solutions like metal grating panels is sure to grow, underscoring their importance in ensuring safe, efficient, and sustainable operations. Whether for industrial floors, walkways, or architectural features, metal grating panels offer a robust solution that meets both functional and aesthetic requirements.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025