- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Metal Grating Load Capacity Charts for Various Applications and Materials

Understanding Metal Grating Load Tables A Comprehensive Guide

Metal grating is an essential component in various industrial and construction applications, offering a range of benefits, including strength, durability, and safety. One of the most critical aspects of using metal grating is understanding the load tables associated with it. This article will explore what metal grating load tables are, their significance, and how to use them effectively in your projects.

What Are Metal Grating Load Tables?

Metal grating load tables are detailed charts that provide information on the load-carrying capacity of different types of metal grating under various conditions. These tables typically include various dimensions, materials, and loading conditions, allowing engineers and designers to select the appropriate grating for their specific needs.

Importance of Load Tables

The primary role of load tables is to ensure safety and reliability in the structures that utilize metal grating. When selecting grating for a project, it’s crucial to understand the expected loads—both static and dynamic—that the grating will need to support. This includes factors such as

1. Live Loads These refer to the weights of people, equipment, and other movable items that will be on the grating. 2. Dead Loads These include the permanent weights of the grating itself and any other structures or materials that are fixed in place. 3. Environmental Loads Factors like wind, snow, or seismic activity can also impact the load-bearing capacity of grating systems.

Using the load tables correctly ensures that the selected grating can safely handle the expected load under the projected conditions.

Components of Load Tables

1. Material Specification Metal gratings are available in various materials, such as stainless steel, aluminum, and carbon steel. The load tables will indicate how the material affects the grating's load capacity.

2. Span Length The distance between the supports beneath the grating plays a significant role in its load capacity. Load tables will show the maximum allowable span for various load conditions.

metal grating load tables

3. Grating Thickness and Section Properties Thicker gratings usually support greater loads. The load tables specify the load ratings for different thicknesses and any specific section properties relevant to performance.

4. Type of Load Tables will differentiate between uniform loads (spread evenly across the surface) and concentrated loads (applied at a single point), providing ratings for both scenarios.

How to Use Metal Grating Load Tables

Using load tables involves several critical steps

1. Determine Load Requirements Calculate the expected live and dead loads for your application, considering environmental factors if applicable.

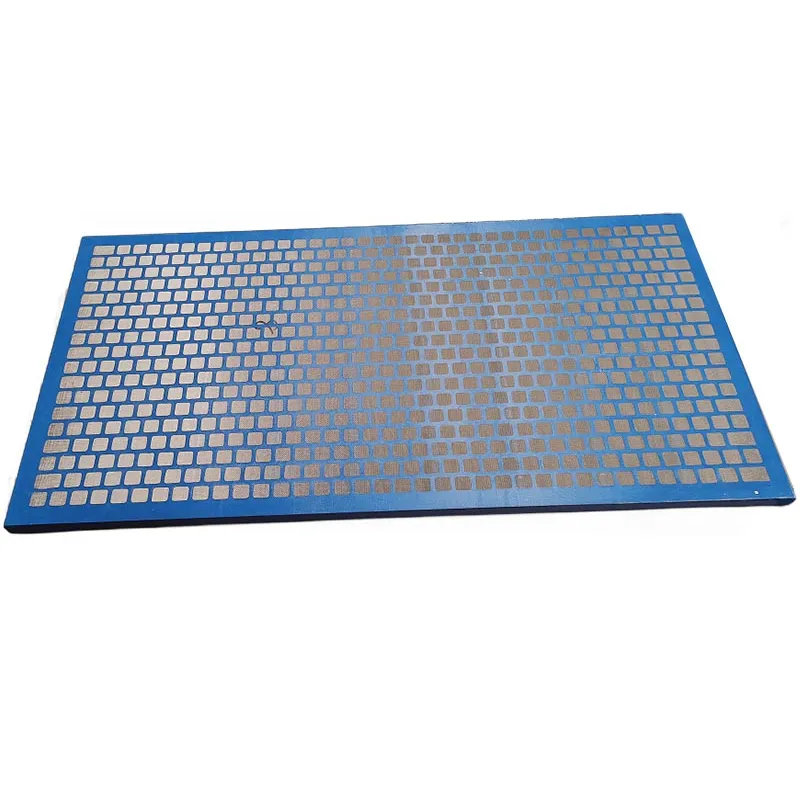

2. Select Grating Type Based on the application requirements, select the type of grating you intend to use—bar grating, expanded metal, or perforated metal, among others.

3. Consult the Load Table Find the corresponding load table for the specific type of grating. Locate the row that matches the grating thickness and material.

4. Evaluate the Span Cross-reference the required span length against the load table's ratings to ensure that it meets or exceeds your calculated loads.

5. Confirm Safety Factors Always account for safety factors as recommended for the specific application, which may necessitate selecting a grating that exceeds the minimum load requirements.

Conclusion

Understanding and using metal grating load tables is essential for ensuring the safety and effectiveness of any construction or industrial project involving metal grating. By thoroughly analyzing the load requirements, selecting the appropriate grating type, and consulting the load tables, engineers and designers can make informed choices that enhance safety and durability. This careful approach ultimately contributes to the longevity and success of the structures that rely on metal grating.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025