- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Durable Metal Catwalk Grating Solutions for Enhanced Safety and Performance in Industrial Settings

The Versatility of Metal Catwalk Grating

In the realm of construction and industrial design, metal catwalk grating plays a crucial role in ensuring safety, durability, and efficiency. As a solution for elevated walkways, catwalks are extensively used in various sectors, including manufacturing, oil and gas, and infrastructure projects. This article explores the significance of metal catwalk grating, its materials, benefits, and applications, along with maintenance considerations.

Understanding Metal Catwalk Grating

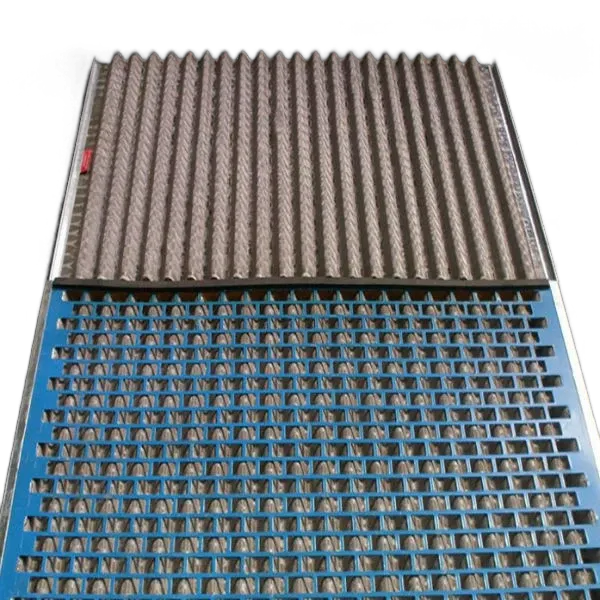

Metal catwalk grating refers to the open-grid structures fabricated from various metals, which are used as walkways or platforms. These grates allow for optimal drainage, reducing water accumulation and minimizing slip hazards. The structure is usually designed to support significant weight loads while providing structural stability.

Common materials used for metal grating include steel, aluminum, and stainless steel. Steel grating, often treated with anti-corrosive coatings, is prevalent in industrial environments where heavy loads are common. Aluminum grating, known for its lightweight nature, is ideal for applications where ease of handling is crucial. Stainless steel grating is favored for its resistance to corrosion and is suitable for food and pharmaceutical industries where hygiene is paramount.

Key Benefits of Metal Catwalk Grating

1. Safety The open design of metal grating enhances visibility and allows for the quick drainage of spills, reducing the risk of slips and falls. The textured surface of grating provides excellent traction even when wet.

2. Durability Metal catwalk grating is resistant to wear and tear, making it an ideal choice for high-traffic areas in industrial settings. Its ability to withstand extreme temperatures and harsh chemicals further enhances its longevity.

3. Low Maintenance Unlike wooden walkways that can rot or require frequent repairs, metal grating demands minimal maintenance. Regular cleaning and inspection are usually sufficient to keep it in good condition.

4. Versatility Metal catwalk grating can be customized to fit various applications, making it suitable for a wide range of industries. Whether it’s for a factory, power plant, or entertainment venue, metal grating provides a reliable answer to elevated walkways.

metal catwalk grating

5. Cost-Effectiveness Though the initial investment may be higher than some alternatives, the long lifespan and low maintenance requirements of metal grating make it a cost-effective solution over time.

Applications of Metal Catwalk Grating

The applications of metal catwalk grating are vast and varied. In industrial settings, it is commonly used for access platforms, machinery walkways, and maintenance platforms, allowing workers to navigate safely around equipment. In commercial buildings, these grates can be utilized in fire escapes, rooftop access, and even as shelving units in storage areas.

In the construction sector, metal catwalk grating is often employed in scaffolding systems, providing a safe and sturdy base for workers. The aviation and maritime industries also rely on metal grating for maintenance areas, ensuring safe access to aircraft and vessels.

In more innovative applications, metal catwalk grating is finding its way into the design of parks and urban spaces, where it is used as part of bridges, walkways, and viewing platforms, combining functionality with aesthetic appeal.

Maintenance Considerations

While metal catwalk grating is relatively low maintenance, some care is required to keep it in optimal condition. Regular inspections should be performed to check for signs of corrosion, especially in coastal areas where salt air can accelerate the degradation process. Cleaning should be conducted to remove debris and ensure optimal drainage capabilities.

For areas that experience heavy traffic or are exposed to harsh chemicals, it may be necessary to schedule maintenance more frequently to address any wear and tear.

Conclusion

Metal catwalk grating embodies a blend of safety, durability, and versatility, making it an integral component in various industries. Its capacity to withstand harsh conditions while requiring minimal maintenance solidifies its place in construction and industrial applications. As industries continue to evolve and innovate, metal catwalk grating will undoubtedly remain a favored choice for ensuring safety and efficiency in aerial workspaces.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025