- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Metal Bar Grating for Enhanced Structural Support and Versatile Applications in Various Industries

Understanding Metal Bar Grating A Comprehensive Overview

Metal bar grating has become an essential feature in various industrial, architectural, and safety applications. It is renowned for its strength, durability, and versatility. This article will explore the different aspects of metal bar grating, including its types, uses, benefits, and installation methods.

What is Metal Bar Grating?

Metal bar grating consists of a series of parallel bars that are spaced equidistantly apart. These bars can be made from various metals, including steel, aluminum, and stainless steel. Depending on the application and environment, the type of metal used can greatly impact the material's performance. The bars are usually joined by a process of welding or forging, resulting in a robust, load-bearing structure.

Types of Metal Bar Grating

There are several types of metal bar grating, each designed for specific applications. The most common types include

1. Welded Grating This type is produced by physically welding the cross bars to the bearing bars. It provides high strength and solid construction. Welded gratings are widely used in industrial settings, as they can handle heavy loads.

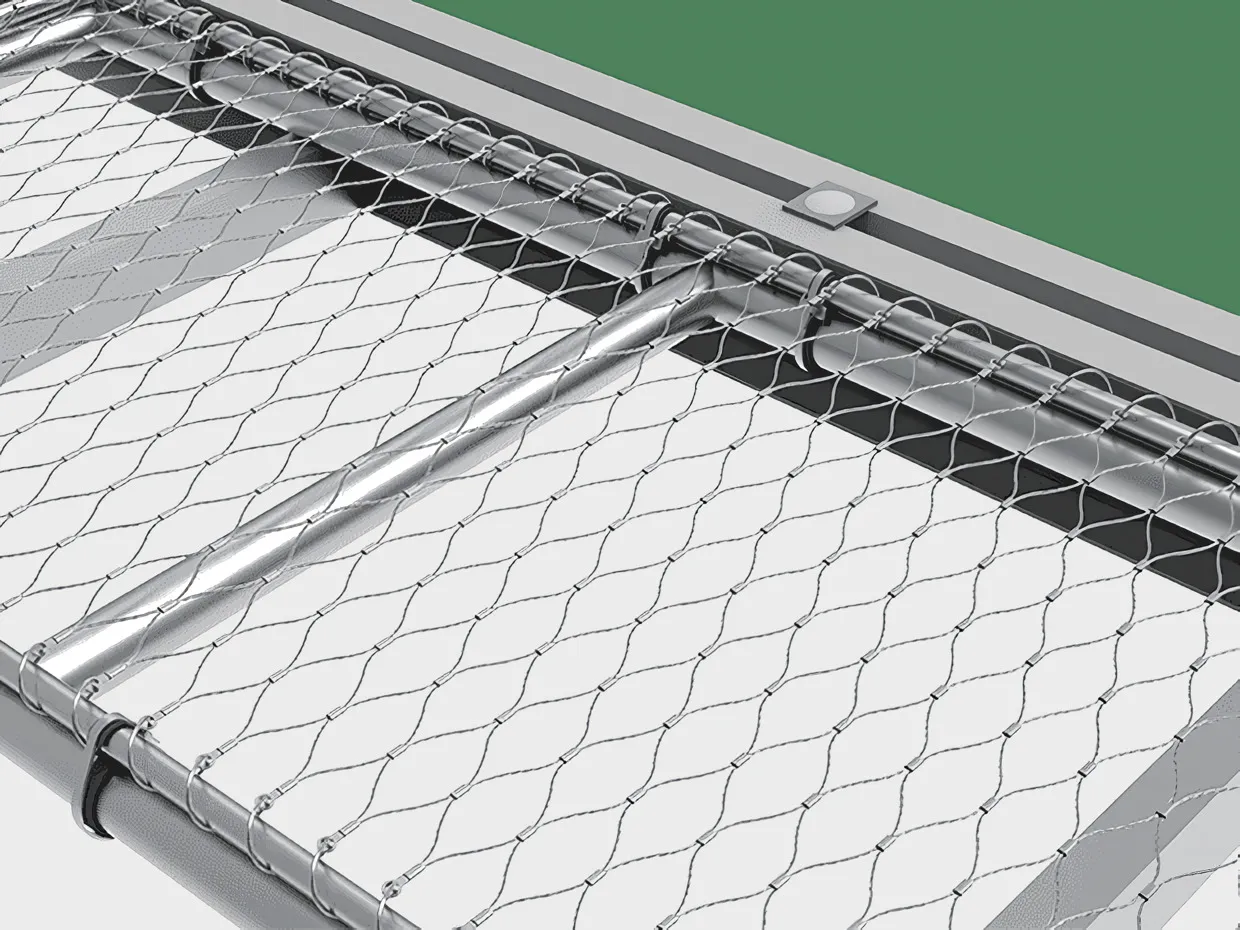

2. Swage Locked Grating A more advanced method involves swaging where the cross bars are mechanically locked into the bearing bars through pressure. This type offers a smooth surface, making it ideal for environments where cleanliness is paramount.

3. Press-Locked Grating In this variation, the cross bars are pressed into the bearing bars without welding. This method allows for faster production and is typically used in less demanding applications.

4. Heavy-Duty Grating Designed to bear significant weight loads, heavy-duty grating is often utilized in places like freight terminals and loading docks. Its enhanced durability helps it withstand harsh conditions.

Applications of Metal Bar Grating

The versatility of metal bar grating lends itself to many applications across different industries

- Industrial Flooring Metal grating is commonly used for walkways, platforms, and floors in industrial facilities. Its open design allows for drainage and reduces the risk of slips due to wet conditions.

metal bar grating

- Safety Grating In environments where safety is a priority, metal bar grating can be installed over equipment or hazardous areas to prevent accidents.

- Drainage Systems Grating is often used in drainage pits and channels. Its design allows debris to flow through while preventing larger objects from blocking the system.

- Architectural Elements Beyond industrial use, metal bar grating is also used in architecture, such as in facades, railings, and decorative elements. Its aesthetic appeal combined with its functionality makes it a popular choice among architects.

Benefits of Metal Bar Grating

Choosing metal bar grating over other flooring or walkways has multiple advantages

- Strength and Durability Metal grating can withstand heavy loads and harsh weather conditions, extending its service life.

- Low Maintenance Unlike traditional materials that may require regular upkeep, metal grating is largely maintenance-free and can resist corrosion, particularly when made from stainless steel or coated with protective finishes.

- Versatility Metal grating can be customized to fit any size or design specification. This makes it suitable for numerous applications across various sectors.

- Cost-Effectiveness While the initial cost may be higher compared to other materials, the long-term durability and low maintenance requirements can make metal bar grating a more economical choice over time.

Installation of Metal Bar Grating

Installing metal bar grating requires careful planning and execution. Proper measurements and cutting of the grating must be conducted to ensure a perfect fit. It is crucial to secure the grating using appropriate fixing methods, whether it be clips, screws, or welding, depending on the specific type of grating and its application. If the installation is in a safety-critical environment, adherence to local safety regulations and standards is paramount.

Conclusion

Metal bar grating is a vital component in numerous industrial and architectural applications. Its combination of strength, durability, and versatility makes it an ideal choice for a wide array of uses. Understanding the types, benefits, and installation methods of metal bar grating can help businesses and individuals make informed decisions in their projects, ensuring both safety and functionality. Whether utilized in an industrial setting or as a design element in architecture, metal bar grating continues to prove its value across sectors.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025