- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

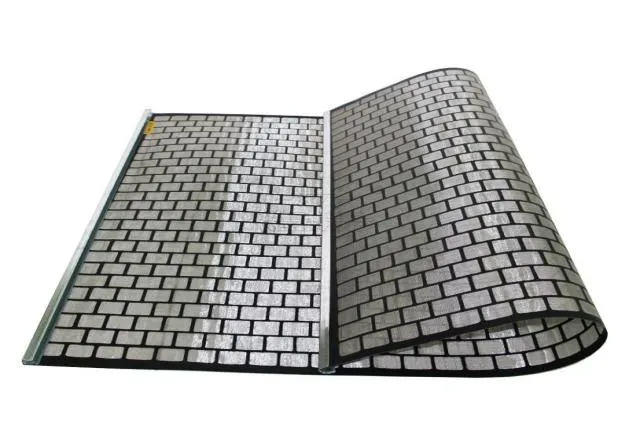

lightweight grating

The Emergence of Lightweight Grating A Revolutionary Advancement in Material Science

In the realm of material science, innovations are constantly reshaping the landscape of engineering and technology. One such advancement that has garnered significant attention is lightweight grating. Offering a host of advantages over traditional materials, lightweight grating has become a transformative solution across various industries. In this article, we delve into the properties, applications, and future potential of lightweight grating.

What is Lightweight Grating?

Lightweight grating refers to a type of structural material characterized by its low weight, high strength, and excellent durability. Typically fabricated from composite materials such as fiberglass or advanced polymers, these gratings are engineered to provide maximum strength while minimizing mass. This key feature makes them particularly valuable in applications where weight is a critical factor, such as aerospace, automotive, and construction.

The manufacturing processes for lightweight grating involve advanced techniques such as pultrusion and extrusion, which allow for the creation of complex shapes without sacrificing structural integrity. As a result, lightweight grating can be designed to meet precise specifications while maintaining a lower environmental impact due to reduced material usage.

Advantages of Lightweight Grating

1. Weight Reduction One of the most significant benefits of lightweight grating is its reduced weight compared to traditional steel and aluminum materials. This reduction in weight not only lowers transportation costs but also contributes to improved fuel efficiency in vehicles and aircraft. In construction, lightweight grating allows for easier handling and installation, saving both time and labor costs.

2. Corrosion Resistance Many lightweight grating materials are inherently resistant to rust and corrosion, thanks to their composite nature. This property is particularly important in applications exposed to harsh environments, such as marine and industrial settings. By reducing the need for protective coatings, lightweight grating can lower maintenance costs and extend the lifespan of structures.

3. High Strength-to-Weight Ratio Despite their lightness, these gratings offer exceptional strength. The advanced materials used in lightweight grating are designed to withstand heavy loads and resist deformation, making them suitable for both supporting structures and functional surfaces.

4. Customization Lightweight grating can be easily tailored to meet specific project requirements. With advancements in manufacturing technology, designers can create gratings with various patterns, colors, and surface finishes, enhancing both aesthetic appeal and functionality.

lightweight grating

Applications of Lightweight Grating

The versatility of lightweight grating has led to its adoption across a wide range of industries

- Aerospace In the aerospace sector, reducing weight is crucial for improving fuel efficiency and enhancing performance. Lightweight grating is used in aircraft flooring, access platforms, and walkways, contributing to overall weight savings.

- Construction In building and construction, lightweight grating is employed in flooring systems, stair treads, and safety barriers. Its ease of installation and resistance to environmental degradation makes it an ideal choice for modern architecture.

- Transportation The automotive industry benefits from lightweight grating in the manufacturing of vehicles where every ounce counts. Lightweight components can lead to better fuel economy and lower emissions.

- Marine Applications In marine settings, lightweight grating is used for decks, walkways, and platforms. Its resistance to corrosion and water damage ensures longevity in demanding maritime environments.

The Future of Lightweight Grating

As the demand for sustainable and efficient materials continues to grow, the future of lightweight grating appears bright. Ongoing research and development efforts are focused on improving the performance of these materials, exploring new composite options, and enhancing their recyclability. Furthermore, as industries strive to reduce their carbon footprint, the adoption of lightweight grating can play a pivotal role in achieving these goals.

In conclusion, lightweight grating represents a significant leap forward in material technology, combining low weight with high strength and durability. Its applications span various industries, providing critical solutions that enhance efficiency, reduce costs, and promote sustainability. As technology continues to evolve, lightweight grating is poised to become an integral component of the infrastructure and manufacturing sectors, paving the way for a more innovative and sustainable future.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025