- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Innovative Thin Grating Technology for Enhanced Light Manipulation and Efficiency

Lightweight Grating Innovations and Applications

In the ever-evolving field of engineering and technology, the demand for more efficient, adaptable, and lightweight materials has become a focal point of research and development. Among these innovations, lightweight grating has emerged as a significant solution, especially in sectors like construction, aerospace, and automotive industries. This article explores the concept of lightweight grating, its materials, benefits, and various applications.

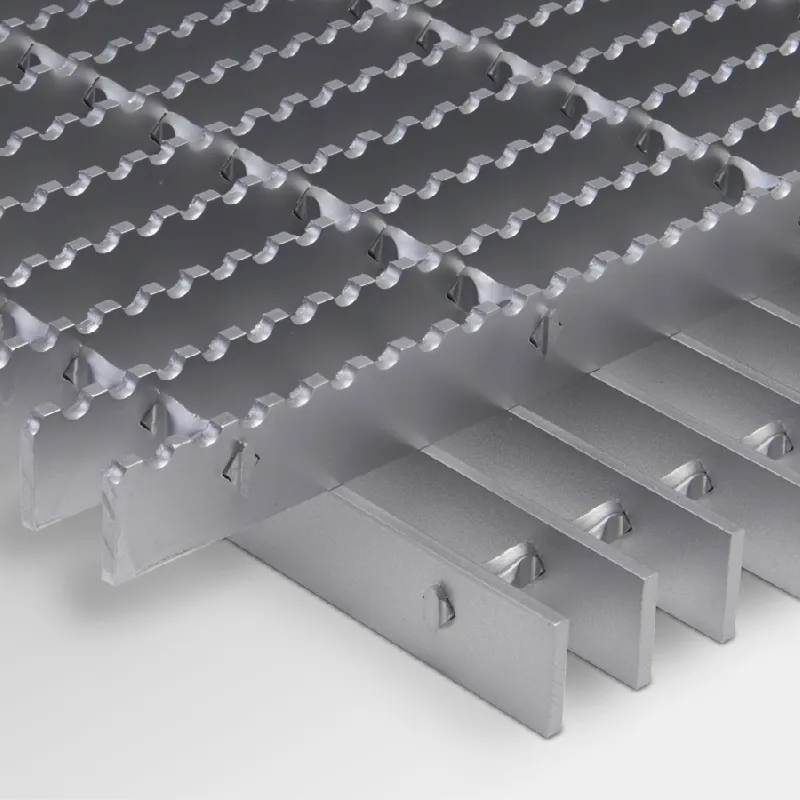

Lightweight grating refers to a structural element that combines high strength-to-weight ratios with enhanced durability and minimal material usage. Traditionally, grating has been manufactured using heavier materials like steel or aluminum, which, while strong, can contribute to higher overall structure weights and increased cost. Lightweight grating, on the other hand, employs advanced composite materials, plastics, and innovative design techniques to minimize weight without sacrificing performance.

One of the primary materials used in lightweight grating is fiberglass reinforced plastic (FRP). FRP grating offers remarkable corrosion resistance, making it ideal for environments where exposure to chemicals, moisture, and harsh weather conditions is common. Moreover, FRP is significantly lighter than its metal counterparts, which can lead to substantial savings in transportation costs and easier installation processes. Additionally, FRP grating is available in various colors and finishes, providing aesthetic advantages alongside its functional benefits.

Another emerging material in the realm of lightweight grating is advanced thermoplastics

. These materials can be engineered to provide exceptional mechanical properties while remaining lightweight. Thermoplastic grating can be molded into complex shapes, enabling innovative designs that were previously impossible with traditional grating materials. This versatility allows for custom solutions tailored to specific structural needs, such as those found in architectural designs or intricate machinery layouts.lightweight grating

The benefits of lightweight grating extend beyond merely reducing weight. By utilizing advanced materials, it enhances overall structural integrity and longevity. Reduced weight contributes to lower energy consumption in transportation and installation, thereby promoting sustainable practices. Additionally, lightweight grating can lead to lower maintenance costs due to its resistance to corrosion and wear, further enhancing its cost-effectiveness over time.

Applications of lightweight grating are broad and varied. In the construction industry, it is used extensively for walkways, platforms, and stairs, where reducing load on support structures is crucial. Its lightweight nature allows for greater flexibility in design and faster installation times, enabling projects to stay on schedule and within budget. Furthermore, in the energy sector, lightweight grating is increasingly used in wind and solar farms, where structures need to withstand environmental stresses while still optimizing efficiency.

In the aerospace and automotive industries, the push for lightweight materials is relentless. Engineers are consistently searching for ways to reduce the weight of aircraft and vehicles to improve fuel efficiency and performance. Lightweight grating can be integrated into various components, from support structures in fuselage designs to lightweight flooring solutions in vehicles, supporting the overall goal of enhancing performance while minimizing environmental impact.

As technology continues to advance, the possibilities for lightweight grating applications are bound to expand even further. Ongoing research in material science and engineering processes promises to unlock new potential in terms of weight reduction, strength enhancement, and design flexibility. In conclusion, lightweight grating represents a significant advancement in engineering and material usage, paving the way for more efficient, sustainable, and innovative solutions in a variety of fields. Its proven advantages in weight savings, durability, and design flexibility make it a valuable choice for contemporary and future projects. As industries look for substantial advancements in reducing environmental impact while enhancing performance, lightweight grating is poised to play a vital role in shaping the future of structural materials.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025