- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

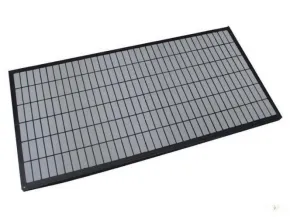

Innovative Design for Efficient Lightweight Gratings in Modern Optical Applications

The Advantages and Applications of Lightweight Grating Technology

In recent years, the field of material science and engineering has seen exponential growth in innovative concepts aimed at enhancing the performance and efficiency of traditional materials. One such notable advancement is the development of lightweight grating technology. This innovation not only addresses the need for high-performance structures but also caters to the modern demands for sustainability and efficiency across various industries.

Understanding Lightweight Grating

Lightweight grating, often referred to as a type of engineered grating, integrates composite materials and advanced manufacturing techniques to reduce the weight while maintaining strength and durability. Traditional grating materials—such as steel or aluminum—can be heavy and cumbersome, posing challenges in terms of transportation, installation, and overall structural load. In contrast, lightweight grating is designed to optimize performance without the burden of excessive weight.

Materials and Design

The core of lightweight grating technology lies in the selection of materials and the design process. Advanced composites, such as fiberglass reinforced plastic (FRP) or other high-strength polymer materials, are commonly utilized. These materials boast a high strength-to-weight ratio, which allows for reduced mass without sacrificing performance. The design of these gratings often incorporates advanced computer-aided design (CAD) software, which enables engineers to simulate and optimize the structural integrity of the grating before manufacturing.

Benefits of Lightweight Grating

1. Reduced Weight The most significant advantage of lightweight grating is its weight reduction. This not only translates to easier handling and installation but also lessens the load on structural frameworks, potentially extending their lifespan.

2. Cost Efficiency While the initial investment for lightweight materials may be higher than traditional options, the overall cost savings become evident in the long term. Reduced transportation costs, simplified assembly, and lower maintenance requirements contribute to a decreased total cost of ownership.

3. Durability and Corrosion Resistance Many lightweight grating materials are inherently resistant to corrosion, making them ideal for use in harsh environments such as chemical plants, wastewater treatment facilities, and coastal areas. This durability ensures a longer service life compared to conventional materials, which often require regular maintenance or replacement.

lightweight grating

4. Sustainability Lightweight grating solutions play a pivotal role in promoting sustainability. By using less material and ensuring longer lifespans, they contribute to resource conservation. Furthermore, advancements in manufacturing processes have led to less waste production, highlighting a more eco-friendly approach.

Applications Across Industries

Lightweight grating technology has a vast array of applications across different sectors

- Construction Used for flooring, walkways, and platform structures, lightweight grating provides safety and durability in buildings, particularly in industrial settings.

- Transportation In the automotive and aerospace sectors, reducing weight is crucial for improving fuel efficiency. Lightweight grating components contribute to overall weight reductions in vehicles, leading to lower emissions.

- Marine Industry Lightweight grating is increasingly used in shipbuilding and offshore platforms. Its corrosion resistance is essential for applications exposed to seawater and harsh marine environments.

- Renewable Energy Solar and wind energy installations benefit from lightweight grating materials, which enable efficient design and less weight on support structures, thereby maximizing energy generation potentials.

- Agriculture In agricultural applications, lightweight grating can be employed in livestock feeding areas or greenhouse flooring, enhancing functionality while minimizing weight.

Conclusion

As industries continue to evolve, the necessity for efficient and sustainable materials becomes paramount. Lightweight grating technology stands out as a significant innovation that meets these demands through its myriad advantages. By providing a solution that combines reduced weight with enhanced performance, lightweight grating is poised to play an integral role in shaping the future of various sectors. With ongoing research and development, the full potential of lightweight grating will undoubtedly continue to unfold, leading to even more widespread applications and benefits.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025