- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

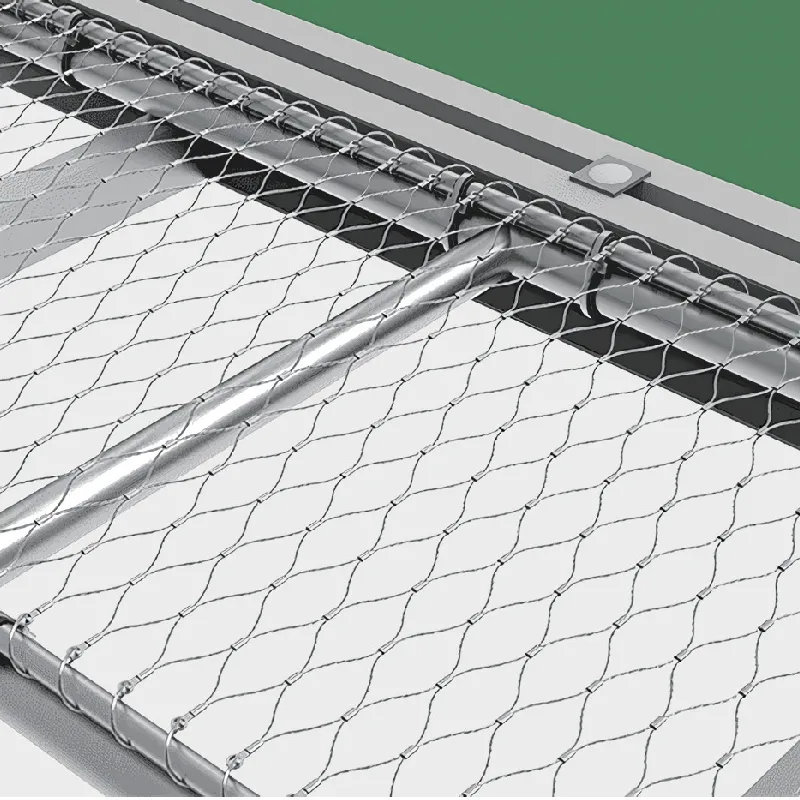

Innovative Applications of Steel Pipe Winding Mesh in Modern Structural Engineering and Design

The Versatility and Importance of Steel Pipe Winding Mesh

Steel pipe winding mesh is a remarkable innovation in the field of construction and industrial applications. This specialized mesh offers unique benefits, enhancing various processes in sectors ranging from construction to manufacturing. As industries evolve and seek more efficient and durable materials, steel pipe winding mesh stands out as a versatile solution for strengthening structures and improving performance.

At its core, steel pipe winding mesh is designed to provide additional support to steel pipes used in a myriad of applications. The mesh is typically made of high-strength steel wires that are woven together, forming a grid-like pattern. This structure enhances the pipe's ability to withstand external pressures, prevent deformation, and prolong its lifespan. Its usage is particularly prevalent in applications requiring high levels of durability and resistance to environmental factors.

One of the primary advantages of steel pipe winding mesh is its ability to strengthen the integrity of the pipes. In scenarios where pipes are subjected to significant stress—such as those found in oil and gas pipelines, water supply systems, and various industrial processes—the mesh acts as a reinforcement layer. This additional support reduces the risk of cracks and failures, which can lead to costly repairs and environmental hazards. By using winding mesh, industries can ensure a greater degree of safety and reliability.

Moreover, steel pipe winding mesh enhances the efficiency of construction projects. Traditional methods often require extensive materials and labor to achieve the necessary strength and support for steel pipes. However, the application of winding mesh can streamline these processes. The mesh can be easily applied, reducing installation time and labor costs. This efficiency is particularly beneficial in large-scale projects, where time and budget constraints are paramount.

steel pipe winding mesh

Another noteworthy aspect of steel pipe winding mesh is its versatility. It can be customized to suit different sizes and types of pipes, making it applicable in a variety of sectors. Whether it's constructing bridges, highways, or residential buildings, the mesh can be tailored to meet specific engineering requirements. Additionally, its corrosion-resistant properties make it suitable for environments where exposure to moisture, chemicals, or extreme temperatures is a concern. This adaptability strengthens its position as a go-to material in many construction and industrial settings.

In terms of environmental impact, steel pipe winding mesh is also a sustainable option. Steel is a recyclable material, and the production of winding mesh typically adheres to environmentally friendly practices. Utilizing steel mesh not only contributes to the longevity of infrastructure but also aligns with the growing emphasis on sustainable building materials.

Furthermore, as industries continue to innovate, the demand for enhanced safety and performance in construction materials increases. Steel pipe winding mesh meets this demand by providing solutions that ensure structural integrity and resilience. Its use is expected to grow in various applications, supporting modern infrastructures that require high standards of durability and reliability.

In conclusion, steel pipe winding mesh represents a significant advancement in construction and industrial applications. Its strength, versatility, and efficiency make it an essential component for reinforcing steel pipes and ensuring their longevity. As industries strive for better performance and safety, steel pipe winding mesh stands as a pivotal solution, reflecting the continuous evolution of materials used in modern engineering and construction. Through its implementation, companies can not only enhance their structural integrity but also contribute to a more sustainable future.

-

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025