- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

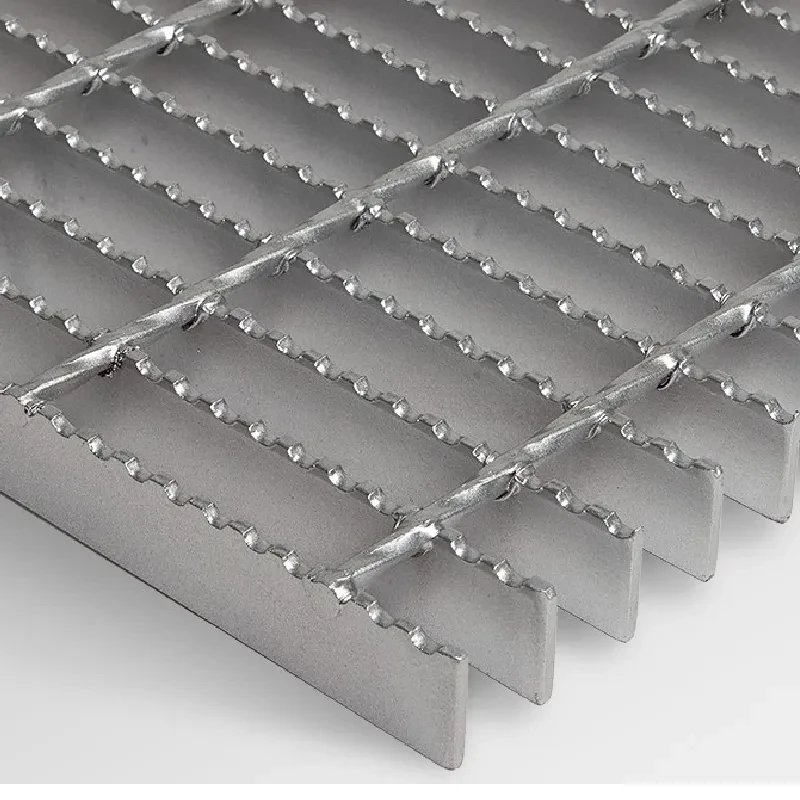

Durable Industrial Metal Grating Solutions for Enhanced Safety and Efficiency in Heavy-Duty Applications

Understanding Industrial Metal Grating Applications, Types, and Benefits

Industrial metal grating is a crucial component in a variety of industrial applications, serving not only functional purposes but also contributing to safety and efficiency across numerous sectors. This article explores what industrial metal grating is, its various types, applications, and the benefits of using metal gratings in different environments.

What is Industrial Metal Grating?

Industrial metal grating is a type of flooring material that consists of a series of longitudinal bars and cross bars formed into a grid pattern. This structure provides a robust, durable surface that allows for the passage of light, air, and fluids while offering excellent load-bearing capacity. Typically made from materials like steel, aluminum, or stainless steel, metal grating can be manufactured to meet specific requirements regarding load capacity, spacing, and surface finish.

Types of Industrial Metal Grating

1. Bar Grating This is one of the most common forms of metal grating, made up of flat bars (or planks) that are placed parallel to each other. The spaces between them can vary based on the application needs, allowing for drainage or airflow.

2. Safety Grating Designed specifically to reduce slipping accidents, safety grating features a textured surface or additional materials that improve traction. It is often used in areas where workers are likely to encounter wet or oily conditions.

3. Expanded Metal Grating This type is fabricated from sheets of metal that are simultaneously cut and stretched to form a mesh-like pattern. This offers increased visibility and ventilation, making it ideal for security applications or as a lightweight alternative.

4. Perf Grating Perforated metal grating is made from panels with a series of holes that enhance drainage and airflow. It is particularly useful in environments that require ventilation without sacrificing strength.

Applications of Metal Grating

Industrial metal grating is widely used in various sectors due to its versatility. Some common applications include

- Walkways and Platforms Metal grating provides safe, slip-resistant walkways in industrial settings, warehouses, and factories.

- Drainage Systems The design of grating allows for efficient drainage in areas prone to water accumulation, such as outdoor facilities and chemical plants.

industrial metal grating

- Manufacturing Facilities In factories, metal grating is essential for creating heavy-duty flooring surfaces that can withstand machinery and equipment loads.

- Chemical Processing The non-combustible properties of certain metal gratings make them suitable for environments where flammable materials are present

.- Transportation Metal grating is often used in pedestrian bridges and airport terminals for durable, maintenance-free flooring solutions.

Benefits of Industrial Metal Grating

1. Durability Metal gratings are built to withstand extreme conditions, making them ideal for heavy industrial environments. They can resist corrosion, impact, and wear.

2. Safety The design of metal grating reduces the risk of slips and falls, which can significantly enhance workplace safety.

3. Cost-Effectiveness With their long lifespan and low maintenance requirements, metal gratings are a cost-effective flooring option in the long term.

4. Versatility Available in various sizes, materials, and finishes, metal grating can be custom-made to fit unique specifications in different applications.

5. Lightweight Compared to solid materials, metal grating is much lighter, reducing the structural load on buildings and allowing for easier installation.

6. Aesthetic Appeal Some styles of metal grating can also enhance the visual appeal of a space while maintaining functionality.

Conclusion

Industrial metal grating plays an indispensable role in numerous applications, providing safety, support, and efficiency across various industries. Understanding the types, applications, and benefits of metal grating can aid businesses in selecting the right solution for their specific needs, ultimately contributing to improved operational performance and workplace safety. Whether in manufacturing, construction, or chemical processing, investing in quality industrial metal grating is a choice that pays dividends in durability, efficiency, and safety.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025