- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

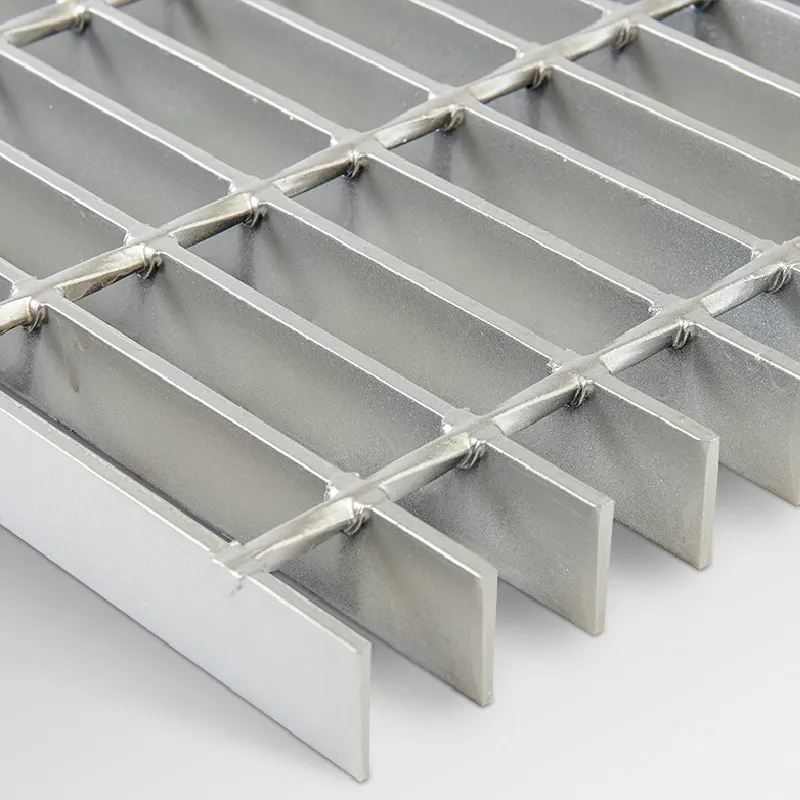

industrial floor grates

Understanding Industrial Floor Grates Importance, Types, and Applications

Industrial floor grates play a pivotal role in various sectors, offering improved safety, functionality, and efficiency. These structures are not merely functional components; they contribute to the overall integrity of industrial spaces, particularly in environments that experience high foot traffic, heavy machinery use, or exposure to hazardous materials. In this article, we will explore the significance of industrial floor grates, the various types available, and their applications across multiple industries.

Importance of Industrial Floor Grates

Industrial floor grates serve several crucial purposes. Primarily, they enhance safety by providing a slip-resistant surface that helps to prevent accidents in workplaces where liquids or debris are common. Safety is paramount in industrial settings, and installations like floor grates can significantly reduce the risk of slips, trips, and falls.

Additionally, industrial floor grates facilitate drainage and ventilation. In many manufacturing plants and warehouses, spills can occur frequently. Grates allow fluids to flow through, preventing the accumulation of hazardous substances on the floor. This also helps maintain a clean working environment, promoting efficiency and productivity.

Moreover, the ability to support heavy loads makes industrial floor grates an essential feature in facilities where heavy machinery operates. They ensure that the flooring can withstand the stress and weight of equipment and materials without compromising structural integrity.

Types of Industrial Floor Grates

1. Steel Grates These are among the most common types of industrial grates due to their durability and strength. Steel grates can be designed to withstand heavy loads and are resistant to wear and tear. They are often used in areas where high traffic and heavy machinery are common.

2. Aluminum Grates Lightweight and corrosion-resistant, aluminum grates are ideal for environments where rust might be a concern. These grates are often used in food processing plants and pharmaceutical facilities where hygiene is crucial.

3. Fiberglass Grates These are known for being lightweight and resistant to chemicals, making them suitable for environments where corrosive materials are prevalent. Fiberglass grates are non-conductive, which adds an additional level of safety in industrial settings.

4. Plastic Grates Although not as strong as steel or aluminum, plastic grates can be beneficial in specific applications, particularly in areas where light loads are present. They are often used in drainage systems and light-duty flooring.

industrial floor grates

5. Composite Grates Made from a mixture of materials, composite grates offer a balance between strength and weight. They can be designed to meet specific requirements, including resistance to chemicals and UV exposure.

Applications Across Industries

Industrial floor grates find applications in a wide range of sectors

- Manufacturing In manufacturing plants, floor grates are primarily used in areas with high machinery use and potential spill hazards. The grates aid in quick drainage and maintain a safe working surface.

- Food and Beverage In the food industry, hygiene standards are paramount. Aluminum and fiberglass grates are commonly used as they offer corrosion resistance and support safe drainage, thus preventing contamination.

- Pharmaceutical Similar to the food industry, pharmaceutical facilities require strict compliance with hygiene standards. Non-corrosive materials like fiberglass are often used to maintain a sanitary environment.

- Waste Management In waste management facilities, floor grates are essential for controlling the flow of liquids and ensuring safety where waste materials are processed.

- Oil and Gas Industrial grates are extensively employed in the oil and gas sector to provide safe working conditions around drilling sites and refineries, where spills of hazardous materials are common.

Conclusion

Industrial floor grates are a vital component in enhancing safety, promoting efficiency, and ensuring cleanliness in various workplaces. With an array of materials and types available, businesses can select the grates that best fit their specific needs, ensuring long-term durability and functionality. As industries continue to evolve, the importance of these structures remains significant, emphasizing the need for thoughtful design and selection in industrial settings. Whether it’s a manufacturing plant, a food processing facility, or an oil refinery, understanding the benefits and applications of industrial floor grates is crucial for maintaining safety and compliance in today’s industrial landscapes.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025