- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

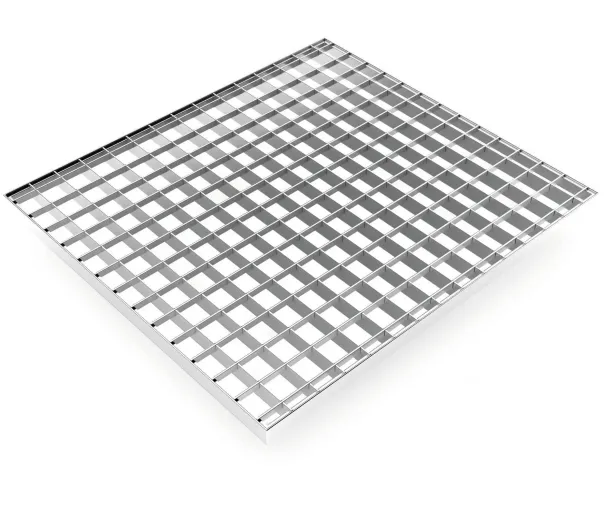

industrial floor grates

Industrial Floor Grates Essential Components for Safety and Efficiency

In the contemporary industrial landscape, safety and efficiency have become paramount. Among the myriad components contributing to these fundamental objectives, industrial floor grates play a vital role. These often-overlooked elements are indispensable in various industrial settings, from manufacturing plants to warehouses, providing not only safety benefits but also aiding in operational efficiency and maintenance.

Functionality and Types of Industrial Floor Grates

Industrial floor grates serve multiple functions. Primarily, they provide a safe walking and working surface while facilitating the drainage of fluids and debris. This is crucial in environments prone to spills or where heavy machinery may be used, as it helps prevent accidents and maintains a clean working atmosphere.

There are several types of industrial floor grates, each designed for specific applications

1. Bar Grates These are made from metal bars and are commonly used in areas where high loads are anticipated. They are robust and allow for excellent drainage, ensuring that fluids can flow away quickly and do not accumulate, which could lead to hazards.

2. Fiberglass Grates Known for being lightweight and corrosion-resistant, fiberglass grates are ideal for environments that involve chemicals or harsh conditions. They are also non-conductive, making them a safe option for electrical installations.

3. Steel Grates Often found in heavy-duty applications, steel grates are strong and durable. They can be coated or treated to resist rust and corrosion, extending their lifespan in challenging environments.

4. Plastic Grates Used in less demanding situations, plastic grates are lightweight and easy to install. They are typically utilized in areas that require adequate drainage without the need for heavy-load capacity.

Safety Considerations

industrial floor grates

In industrial settings, injuries due to slipping, tripping, or falling can have severe repercussions. Industrial floor grates mitigate these risks effectively. By allowing for proper drainage, they ensure that surfaces remain dry and free from hazardous fluids, reducing the likelihood of accidents. Moreover, many grates have slip-resistant surfaces to provide better traction, which is particularly important in environments where employees are on their feet for prolonged periods.

Regular maintenance is essential to maximize the safety benefits provided by floor grates. Routine inspections can help identify wear and tear, ensuring that any damaged sections are repaired or replaced promptly. Additionally, cleaning debris from the grates and ensuring that drainage areas are clear can prevent blockages that might lead to standing water and subsequent hazards.

Enhancing Operational Efficiency

Beyond safety, industrial floor grates can significantly enhance operational efficiency. By streamlining drainage processes, these grates help maintain cleaner floors, which in turn can lead to smoother workflow operations. For instance, in a manufacturing plant, minimizing downtime due to spills or cleaning can translate to improved productivity levels.

Furthermore, the choice of grate material can influence ongoing operational costs. For example, while steel grates may have a higher initial investment, their durability might save costs on replacements and maintenance over time. On the other hand, fiberglass or plastic options could offer greater short-term savings but might need more frequent replacements in high-stress situations.

Environmental Considerations

In addition to their practical applications, the use of industrial floor grates can also contribute to environmental sustainability. Many modern grates are designed with recyclable materials, minimizing the ecological footprint of industrial operations. Furthermore, by promoting better drainage and reducing fluid spills, these grates can assist in preventing soil and water contamination, aligning with best practices in environmental stewardship.

Conclusion

Industrial floor grates are more than just functional components of an industrial facility; they are integral to promoting safety, enhancing efficiency, and supporting environmental sustainability. With the variety of types available, businesses can select the appropriate floor grates to meet their specific needs, ensuring a safer and more productive working environment. Investing in quality industrial floor grates is not merely a matter of compliance; it represents a critical step towards safeguarding workers and boosting operational success. As industries continue to evolve, so too will the technologies and designs of these essential components, ensuring they remain at the forefront of safety and efficiency in the workplace.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025