- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

helideck netting

The Importance of Helideck Netting in Offshore Operations

In the realm of offshore operations, safety is paramount. One of the critical components that ensure the safety of helicopter landings and take-offs on offshore platforms is helideck netting. This specialized netting system plays an essential role in preventing accidents and enhancing operational efficiency. In this article, we will explore the significance of helideck netting, its design features, and its impact on offshore operations.

The Role of Helideck Netting

Helidecks serve as landing pads for helicopters transporting personnel and supplies to and from offshore facilities. These landings are often executed under challenging weather conditions and in high-stress environments. To bolster safety measures, helideck netting is employed to minimize the risks associated with helicopter operations.

Primarily, helideck netting is designed to catch any falling objects that may inadvertently be released during takeoff or landing. This is a critical safety feature, as loose tools or equipment can pose a significant danger to personnel working on the deck below or nearby platforms. By ensuring that no item falls overboard, helideck netting plays an essential role in protecting both human life and valuable offshore equipment.

Design Features of Helideck Netting

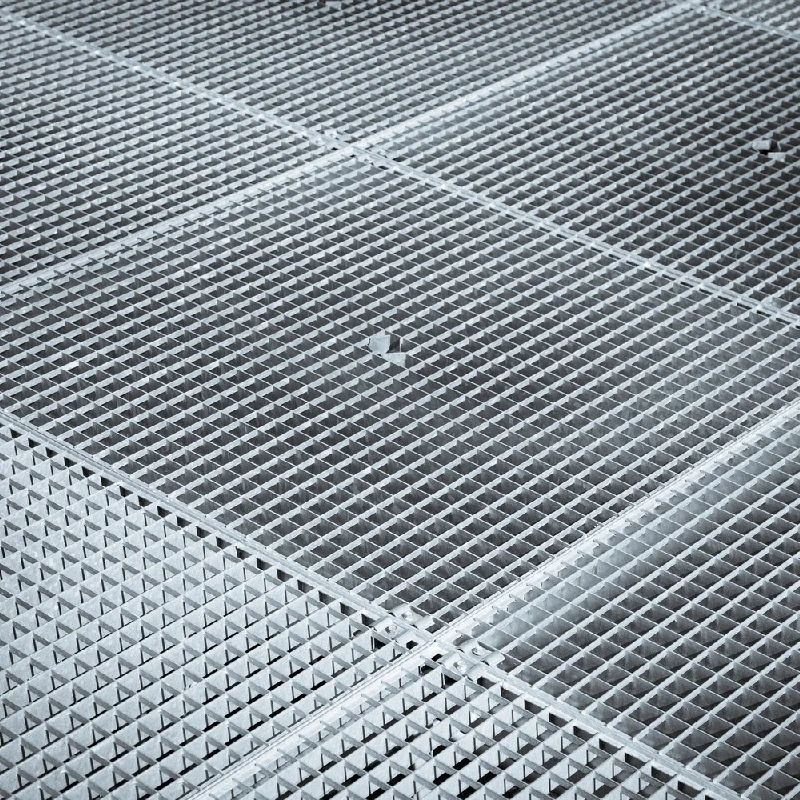

Helideck netting is typically made from high-strength materials that can withstand harsh offshore conditions. The design must account for factors such as wind, rain, and the corrosive nature of saltwater. High-density polyethylene (HDPE) and other synthetic fibers are commonly used for their durability and resistance to environmental degradation.

The mesh of the netting must also be finely woven to ensure that small tools and equipment do not pass through. This is crucial for maintaining safety standards and preventing potential hazards associated with falling items. Moreover, the netting must be anchored securely to the helideck to withstand strong winds and the vibrations produced by landing helicopters, ensuring that it remains in position during operations.

helideck netting

Enhancing Operational Efficiency

Besides enhancing safety, helideck netting contributes to overall operational efficiency. In offshore operations, every second counts. Delays can lead to increased costs and operational frustrations. The presence of helideck netting allows for quicker turnaround times as personnel can work with less worry about the safety of loose items. Crews can focus on loading and unloading tasks, knowing that there is a safety mechanism in place to catch anything that might fall.

Furthermore, the psychological benefit of having safety measures like netting in place cannot be overstated. Crew members are more likely to perform their duties with confidence when they know that safety standards are being upheld. This can lead to improved morale, enhanced productivity, and a more efficient workflow.

Compliance and Regulatory Standards

Adhering to safety regulations is a cornerstone of offshore operations. Regulatory bodies such as the International Maritime Organization (IMO) and various national agencies have established guidelines regarding helideck safety equipment, including netting. Operators must ensure that their helidecks are equipped with compliant netting systems that meet or exceed these standards.

Regular inspections and maintenance of helideck netting are essential to ensure its continued effectiveness. Aging infrastructure, wear and tear, and environmental factors can degrade netting performance over time. Consequently, operators must invest in proper training and resources to regularly assess the condition of helideck netting and replace it when necessary.

Conclusion

In summary, helideck netting is an indispensable component of offshore aviation safety. Its ability to catch falling objects not only protects personnel and equipment but also enhances operational efficiency. By utilizing high-quality materials designed to withstand challenging conditions, helideck netting ensures that offshore operations can continue with minimal risk. Moreover, compliance with regulatory standards reinforces the importance of safety in all offshore activities. As the strive for safety continues in the offshore industry, helideck netting will remain a crucial element in safeguarding lives and ensuring smooth operational workflows. As such, investing in quality helideck netting systems is not only a regulatory requirement but a moral imperative in the demanding world of offshore operations.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025